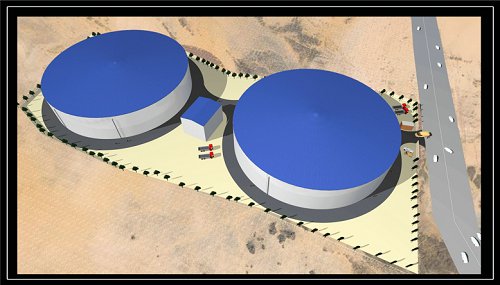

沙特Abha区域二期战略水罐Rawna水罐工程

Saudi Arabia Strategic Water Reservoirs for Urban Abha-Phase 2-Rawna Tanks

1. Project Back Ground:

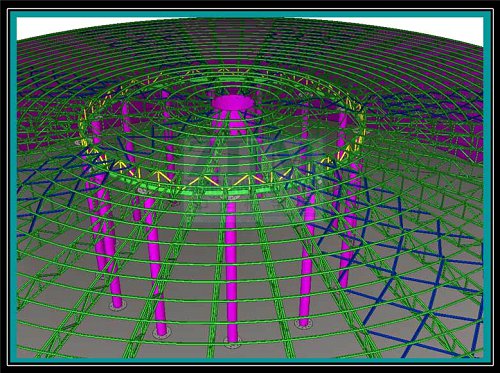

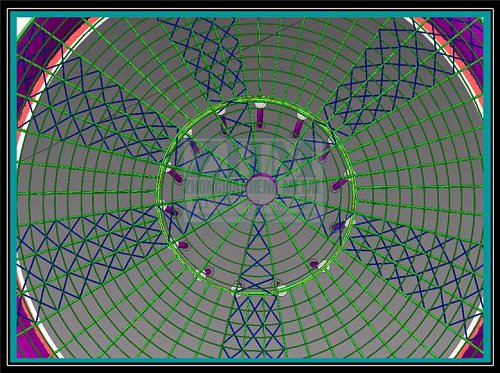

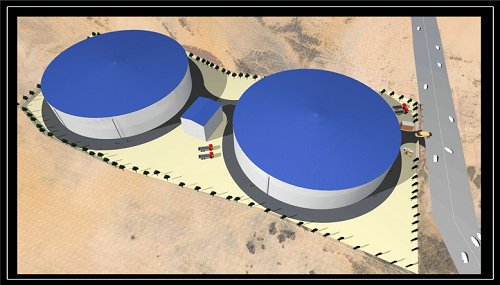

Total Tonnage: 6100Ton, including two isolated water reservoir tanks size at 95.000M Diameter and 19m Height, Total 125000m2 capacity per tank

Location: Urban Abha

Raw Material: ASTM A537 Cl.1 for Shell course No.1 , 2 and 3,

ASTM A572 Gr.50 For Others

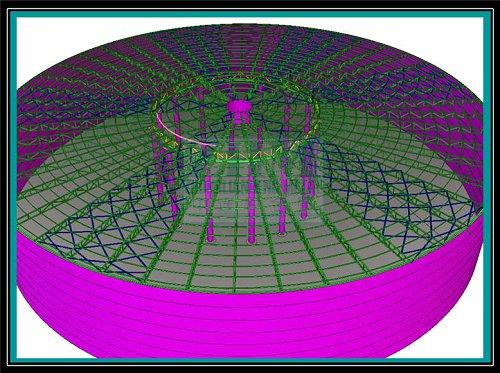

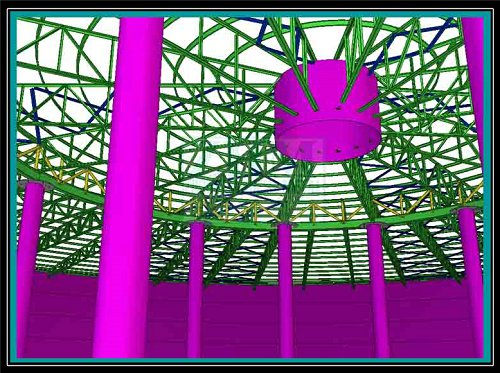

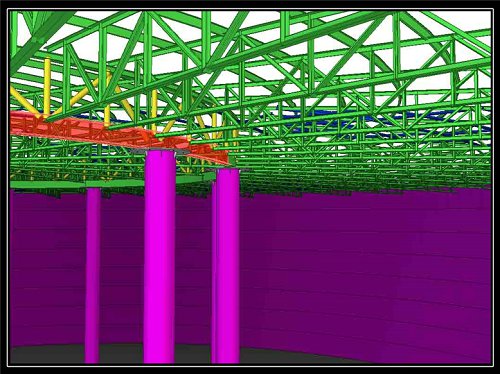

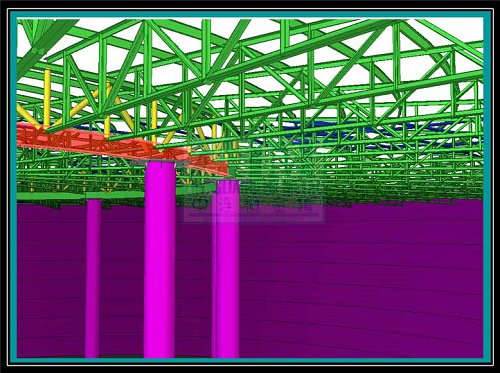

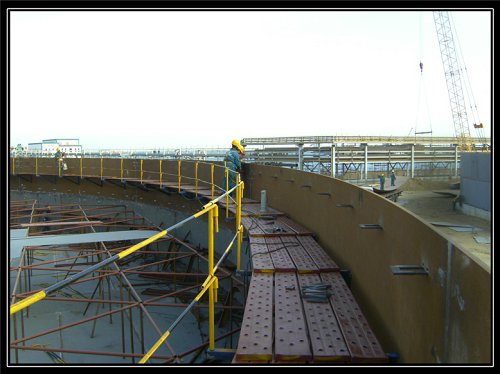

Structure Type: Water Tank(Dia.95mxHeight19m) plus middle tubular columns and truss space frames

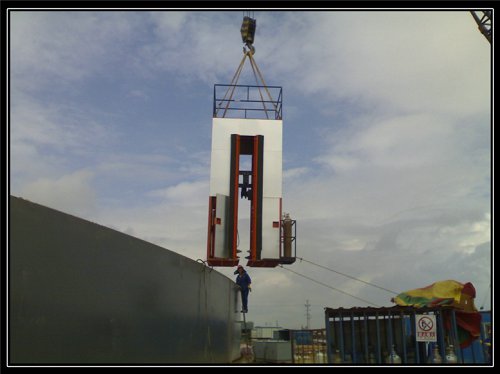

Scope of supply: Engineeering, procurement, construction and commissioning for the shell materials, structure support materials, tubeworks, painting

Single Unit of Tank: 2700T+320T Column&truss support system

Structure Type: Vertical Type Water Tank

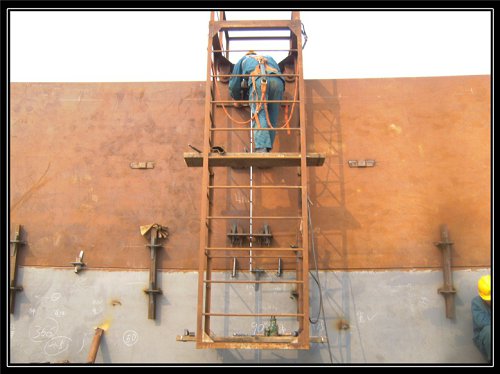

Structure Description: Large volume of welding plate work and high requirement on the welding quality, welding distortion control requirement, long water filling & testing period.

The workers shall strictly carry out the construction as per the Construction Plan

Construction Site: Khamis Mushait, Saudi Arabia

2.Design and construction Basis

SYSTEM ONE:

Original construction drawings and technical requirement from client.

Contract and tendering documents(Commercial&Technical), general conditions and special conditions

ASTM API 650, Welded Tanks for Oil Storage, 11th Edition

AWWA D 100: Welded Carbon Steel Tanks for Water Storage

AWWA D 105, DISINFECTION OF WATER STORAGE FACILITIES

BS 5950(Steel Manufactures Industrial Standards,

SBC 301:Saudi Building Code Requirements

API 510:Pressure Vessel Inspection Code

SYSTEM TWO:

GBJ128-90(Vertical Cylinder Shell Steel Welded Oil Tank Construction and Acceptance Code);

GB50235-97(Industrial Metal Pipeline Project Quality Acceptance Code);

GB50236-98(Site equipment and industrial pipeline welding project construction acceptance code);

JB4730-94(Pressure vessel NDT Testing Code);

SH3046-923(Oil&Chemical Vertical Cylinder Shell Welded Tank Design Code);

SHS3048-1999(Oil&Chemical Steel Welded Tank Equipment Seismic Load Design Code);

Q/HD0026-1995(Vertical Cylinder Shell Welded Tank Anti-corrosion and Insulation Project Construction and Acceptance Code);

GB4053.2-1993(Fixed Type Steel Ladder);

GB8923-88(Steel Corrosion Grade Before Painting)

Company Internal QUALITY CONTROL MANUEL and QUALITY SYSTEM AND PROCEDURE DOCUMENTS

In case of any conflication between the above mentioned items, the sequence of SYSTEM ONE shall be deemed as the priority List.

3. Tank Parameters:

Volume: 125000m2

I.DxWall thk: 95m(3@18mm&2.2/2.4/2.4m(W),2@30mm&2.4m(W),3@45mm&2.4m(W);

Height: 19M(Single Ring Plate=2400mm,U.N.O);

Liquid storage height: 18m

Material Grade: ASTM A572 GR.50

Design Temperature: 50℃

Maximum Temp of stored liquid: 40 ℃

Live load on roof: 1kN/m2, wind load: 160km/h

Seismic load acceleration=0.12g

Medium: Fresh water @ density 1000kg/m3

Steel Quantity: Refer to the Bill of quantity and quotation

Bottom Plate: 14mm

Welding specifications: API650

Inlet opennings: 600mm dia. Outlet opennings: 700mm dia.

Drainage openning: 3x200mm Overflow openning: 600mm

" "1. Project Back Ground:

Total Tonnage: 6100Ton, including two isolated water reservoir tanks size at 95.000M Diameter and 19m Height, Total 125000m2 capacity per tank

Location: Urban Abha

Raw Material: ASTM A537 Cl.1 for Shell course No.1 , 2 and 3,

ASTM A572 Gr.50 For Others

Structure Type: Water Tank(Dia.95mxHeight19m) plus middle tubular columns and truss space frames

Scope of supply: Engineeering, procurement, construction and commissioning for the shell materials, structure support materials, tubeworks, painting

Single Unit of Tank: 2700T+320T Column&truss support system

Structure Type: Vertical Type Water Tank

Structure Description: Large volume of welding plate work and high requirement on the welding quality, welding distortion control requirement, long water filling & testing period.

The workers shall strictly carry out the construction as per the Construction Plan

Construction Site: Khamis Mushait, Saudi Arabia

2.Design and construction Basis

SYSTEM ONE:

Original construction drawings and technical requirement from client.

Contract and tendering documents(Commercial&Technical), general conditions and special conditions

ASTM API 650, Welded Tanks for Oil Storage, 11th Edition

AWWA D 100: Welded Carbon Steel Tanks for Water Storage

AWWA D 105, DISINFECTION OF WATER STORAGE FACILITIES

BS 5950(Steel Manufactures Industrial Standards,

SBC 301:Saudi Building Code Requirements

API 510:Pressure Vessel Inspection Code

SYSTEM TWO:

GBJ128-90(Vertical Cylinder Shell Steel Welded Oil Tank Construction and Acceptance Code);

GB50235-97(Industrial Metal Pipeline Project Quality Acceptance Code);

GB50236-98(Site equipment and industrial pipeline welding project construction acceptance code);

JB4730-94(Pressure vessel NDT Testing Code);

SH3046-923(Oil&Chemical Vertical Cylinder Shell Welded Tank Design Code);

SHS3048-1999(Oil&Chemical Steel Welded Tank Equipment Seismic Load Design Code);

Q/HD0026-1995(Vertical Cylinder Shell Welded Tank Anti-corrosion and Insulation Project Construction and Acceptance Code);

GB4053.2-1993(Fixed Type Steel Ladder);

GB8923-88(Steel Corrosion Grade Before Painting)

Company Internal QUALITY CONTROL MANUEL and QUALITY SYSTEM AND PROCEDURE DOCUMENTS

In case of any conflication between the above mentioned items, the sequence of SYSTEM ONE shall be deemed as the priority List.

3. Tank Parameters:

Volume: 125000m2

I.DxWall thk: 95m(3@18mm&2.2/2.4/2.4m(W),2@30mm&2.4m(W),3@45mm&2.4m(W);

Height: 19M(Single Ring Plate=2400mm,U.N.O);

Liquid storage height: 18m

Material Grade: ASTM A572 GR.50

Design Temperature: 50℃

Maximum Temp of stored liquid: 40 ℃

Live load on roof: 1kN/m2, wind load: 160km/h

Seismic load acceleration=0.12g

Medium: Fresh water @ density 1000kg/m3

Steel Quantity: Refer to the Bill of quantity and quotation

Bottom Plate: 14mm

Welding specifications: API650

Inlet opennings: 600mm dia. Outlet opennings: 700mm dia.

Drainage openning: 3x200mm Overflow openning: 600mm