The "Reefer Container Monitoring System" successfully replaced the traditional mode of manual handing operations. Real-time monitoring of reefer containers and abnormal alarms are realized, which effectively improves the intelligent monitoring level of reefer containers and improves the quality of cold chain logistics.

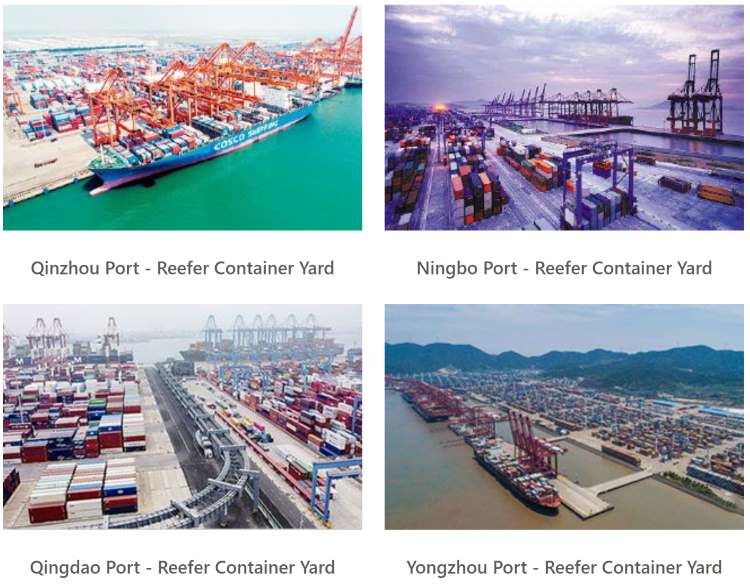

Application Scenario & Case

Ningbo Port - Reefer Container Yard

Qingdao Port - Reefer Container Yard

Yongzhou Port - Reefer Container Yard

Product Description

Collecting Data In Real Time |

Collecting Data In Real Time Through the collection, transmission and monitoring of real-time data, to reduce manual handing operations |

|

|

|

Abnormal Inspection Alarm |

Abnormal Inspection Alarm The whole process of automatic data collection/reporting/storage of refrigerated container, real-time automatic inspection of fault alarms about refrigerated containers |

|

|

|

Data Visualization |

Data Visualization Adopt 2D/3D data visualization management to realize the informatization of data management and precision of that |

The Advantage of Product

|

Automatic Inspection And Warning Check with data collectors, save labor costs and eliminate human error, respond quickly to discrepancies and warn of heat load events, reducing costly claims |

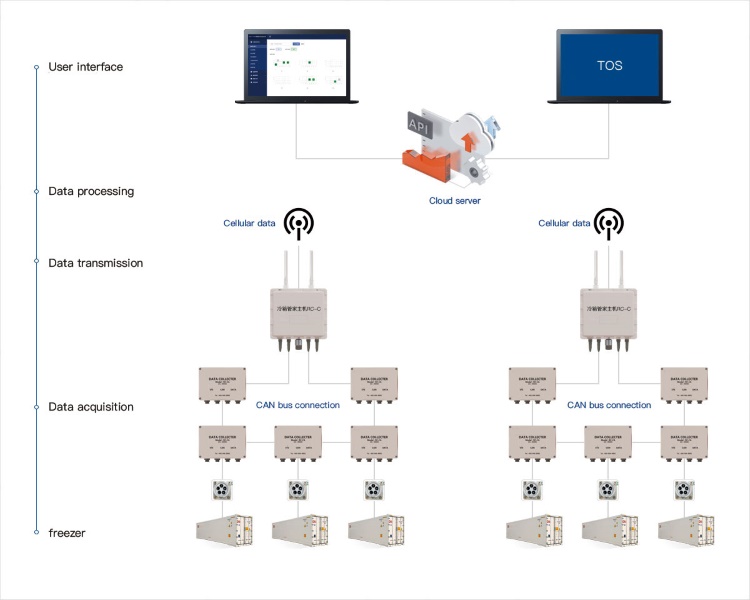

Data Transmission - Multiple Methods Available Communication between equipment and server: Ethernet, WIFI, 4G cellular network, port designated private network, etc. |

|

|

|

|

Domestic Products And Data Security The product has a full set of independent intellectual property rights, patent certificates, soft works, etc.; data security: support the SM2/SM3/SM4/SM9 encryption algorithm issued by the China's State CryptographyAdministration' |

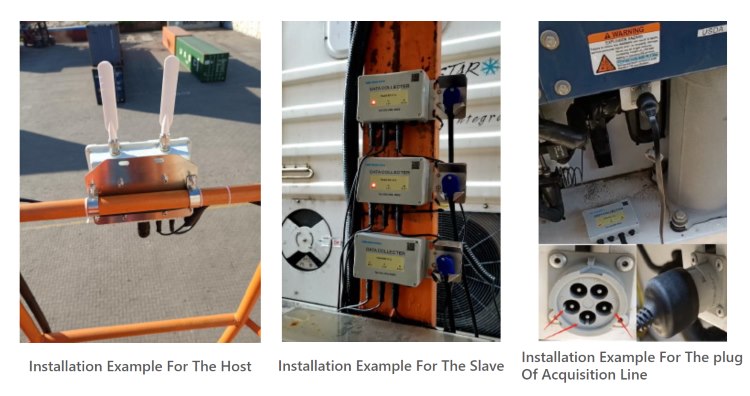

Equipment Use - Simple and Practical The equipment is simple and efficient to use. When the reefer container crew plugs the power supply into the reefer container, they can insert the plug of the data acquisition line by the way. |

|

|

|

|

Visual Management Visual management makes the production management process more intuitive, makes information communication more effective, and visualizes the information inside the port and yard, so as to achieve transparent and accurate management |

Equipment Maintenance - Simple and Convenient Troubleshoot the indicator lights of the data collector, and check the bolt loosening of the equipment installation |

Monitoring Hardware Products For Reefer Containers

The "Reefer Container Monitoring System" Host: RC-C |

The "Reefer Container Monitoring System"Slave: RC-CA |

|

|

|

|

|

|

The "Reefer Container Monitoring System" Host: RC-C It is installed on the shelf of reefer container, collects the real-time data from data collector of each reefer container, and transmits upload data to the system server. |

The "Reefer Container Monitoring System"Slave: RC-CA Installed on the shelf of reefer containers, collecting real-time data (such as temperature, supply air and return air) of major brands of reefer containers , and transmit them to the "Reefer Container Monitoring System" . |

The platform of the "Reefer Container Monitoring System" and server of that It is installed in the computer room of the user information management center (IT department), and the deployed server is delivered to the customer for daily maintenance management. |

System Structure

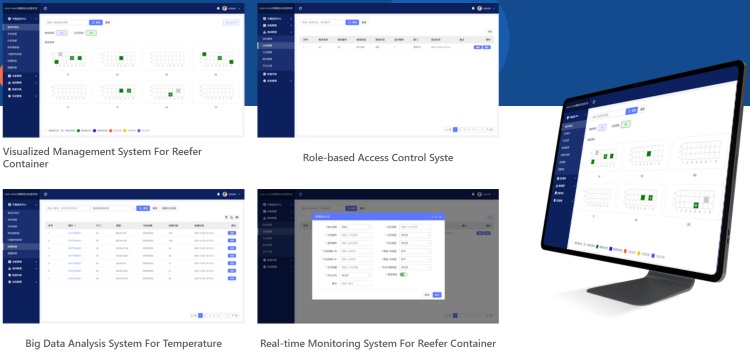

Platform Display

Role-based Access Control Syste

Big Data Analysis System For Temperature

Real-time Monitoring System For Reefer Container

Parameter Specification

|

Product Name |

The monitoring terminal of the "Reefer Container Monitoring System" : the host of the CAN version |

The monitoring terminal of the "Reefer Container Monitoring System" : the slave of the CAN version |

|

Product Type |

RC-C |

RC-CA |

|

Size |

300mm150mm95mm |

100mm*68mm*50mm |

|

Material |

304 Stainless Steel |

ABS Material |

|

Weight |

-- -- |

- -- |

|

Power Supply Equipment |

DC12~24V |

DC12~24V |

|

Method of Data Transmission |

Host & Server: Ethernet, Optional: WIFI/Cellular Network |

Master-slave: CAN Bus |

|

Monitor The Number Of Reefer Containers |

≤32 Channels |

One-To-One |

|

Communication Interface Of Reefer Containers |

Communication Between Slave And Reefer Container: RS232 |

-- |

|

Data Reporting Frequency |

>40S' |

>40S' |

|

Protection Class |

IP67 |

IP67 |

|

Operating Temperature |

-40°C~+85°C |

-40°C~+85°C |

|

Operating Humidity |

5%RH~95%RH |

5%RH~95%RH |

|

Prompt Status |

None |

4 Channel LED |

|

SIM Card Interface |

1 |

-- |

|

Processor |

ARM7 |

-- |

|

Operating System |

FreeRTOS |

-- |

|

Power Rating |

≤10W |

-- |

|

Wireless Interface |

SMA |

-- |

|

Localstorage Capability For Data |

It can store ≥3000 data of reefer containers, at least 60 reefer containers can work together for 24 hours, and one piece of data can be stored half an hour. |

-- |

|

|

|

|

|

|

|

|

Why ZHM Huawu Integrated Cold Chain Reefer Container Monitoring System?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Integrated Cold Chain Reefer Container Monitoring System ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com