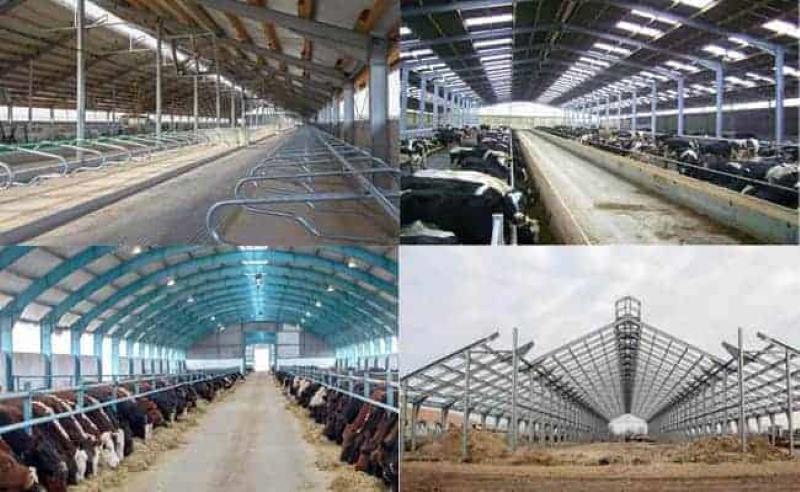

Steel structure cowsheds play a vital role in modern animal husbandry. Its rapid construction, spacious ventilation, superior thermal insulation performance, and durability provide a comfortable, safe, and efficient growing environment for cattle.

During the construction process, reasonable site selection, scientific layout, and careful design are the key factors to ensure the success of steel structure cowsheds, bringing more scientific and sustainable development opportunities to the animal husbandry industry.

Table of Contents

1.1.Large width, spacious, and ventilated inside:

1.2.Good thermal insulation:

1.3.Durability:

2.What factors need to be considered when building a steel structure cowshed?

2.1.1. Select the appropriate address.

2.2.2. The layout should be reasonable.

2.3.Properly design production areas, management areas, feces treatment areas, and isolation areas.

2.4.The design of the steel structure cowshed must be reasonable and thoughtful.

Advantages of steel structure cowsheds:

Large width, spacious, and ventilated inside:

Steel structure cowsheds can provide cattle with a more comfortable and hygienic environment, which can not only improve the production performance of livestock and reduce the occurrence of diseases but also reduce the pressure on natural pastures.

What factors need to be considered when building a steel structure cowshed?

The steel cowshed should be built on flat ground and at a relatively high location. Do not build in depressions to prevent damage caused by heavy rains during the summer flood season. Livestock breeding has a strong smell, and cattle sheds should be far away from residential areas, schools, hospitals, markets, other living areas, and major traffic arteries.

The layout should be reasonable.

Design a cowshed of reasonable size according to the number of cattle raised and the floor area. The cowshed door is made into a push-pull type, which is convenient for cattle to enter and exit. The floor inside the house needs to be dry and flat, solid and wear-resistant, with good scrubbing performance, impervious to water, not slippery, and should not be too hard.

A milking room should be set up in a large dairy farm, including a milking table, a milk processing room, a washing room, a machine room, a boiler room, and other auxiliary rooms. The location of the milking room must consider the walking route of the cows and the convenience of milk collection and has higher requirements in terms of construction and sanitary conditions.

Properly design production areas, management areas, feces treatment areas, and isolation areas.

The design of the steel structure cowshed must be reasonable and thoughtful.

The node structure of the cowshed steel structure building is relatively complex, and there are many forms of welded joints. Moreover, the cowshed structural engineering has a relatively high building height and a large span, which requires relatively high steel structure design requirements.

Depending on the size of the cattle farm, the number of cattle, the area of cattle sheds, and other buildings should be 15% to 20% of the total site area. The most commonly used roof is double-pitched. This roof can be applied to larger-span cattle sheds and used for all types of cattle of all sizes. This type of roof is economical, has good thermal insulation properties, and is easy to construct. The door should be more significant to facilitate the entry and exit of cattle, and it can be designed as a double door or rolling shutter door. The windows should also be more significant for better lighting.

The safety, earthquake resistance, impact resistance, and short construction period of steel structure buildings are suitable for livestock breeding buildings.

Why ZHM Huawu Metal Steel Structure Cowsheds | Steel Frame Cow Barns ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Steel Structure Cowsheds | Steel Frame Cow Barns ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com