Electrical Steel Substation Structures in Steel Works | ZHM Huawu Steel,China

Electrical Steel Substation Structures in Steel Works | ZHM Huawu Steel,China

Before electricity can travel into final consumer's home, it must pass through a substation first. A substation is an assemblage of equipment where electrical energy is passed in order to be stepped up or stepped down.

Transformers inside a substation change the voltage levels between high transmission voltages and lower distribution voltages. The high transmission voltages are used to carry electricity longer distances, like across the country, whereas lower distribution voltages travel to industrial, commercial or residential consumers.

In a T&D system, the major components typically consist of transmission lines, distribution lines, substations and switchyards.

An electrical substation is a collection of equipment used in order to step up or step down electrical currents before they can be used. The most common structures you’ll find in an electrical substation include:

Dead-End Substation Steel Structures

Dead end substation structures are located at the point in the substation where the line angles off or ends. They are usually made with heavy steel in order to carry heavy tension, but they can also be made of the same materials as the other structures in the substation, such as wood poles, concrete, tubular steel or aluminum lattice. The most common dead-end structures are A-Frame steel structures and H-Frame steel structures. A dead-end tower is fully self-supported and at the end of each conductor, it uses horizontal strain insulators to resist unbalanced forces. Dead-end towers are often used as a transition to the entry of a slack-span, but they can also be used when the circuit turns into a buried cable when a line of transmission changes direction sharply or simply to reduce the likelihood of a serious collapse.

Dead-end towers are used to minimize the tower failures that might result from the failure of a conductor. An in-line dead-end tower will be built with two pairs of strain insulators intended to support the lines from both directions, while the lines are connected by a jumper.

Electrical Steel Substation Structures in Steel Works: H-Frame Dead End Substation Steel Structures

Electrical Steel Substation Structures in Steel Works: A-Frame Dead End Substation Steel Structures

A static pole is a singular, free-standing pole used in order to protect all of the equipment in a substation from lightning strikes by acting as a barrier. Static poles can be made of various materials, such as fiberglass, concrete, metal or wood, and the number of poles a substation requires will depend on the substation’s size. Static poles are often referred to as telegraph posts, hydro poles, power poles, telephone poles, or transmission poles, depending on their function.

Static poles may or may not have overhead shield wires attached to enhance protection. It depends on the size of the substation as to how many static poles are needed.

NOTE: Tapered tubular design is typically efficient and economical in dead-end and static pole situations when compared to AISC standard shape structures.

In order to enhance the pole’s protective qualities, they can also have shield wires attached overhead to protect equipment such as fiber optic cables, electrical cables, street lights, and transformers. Routing these cables overhead is an affordable way of keeping them out of the path of any vehicles and people while keeping them insulated from the ground. Today, static poles are often replaced by underground distribution lines in residential neighborhoods because they can be perceived as an eyesore.

Bus Supports/Equipment Stands Substation Steel Structures

Bus supports are one of the most straightforward structures that you’ll find within a substation. The main function of a bus support is to connect low and high voltage equipment at electrical switchyards and battery banks. Bus supports are both uninsulated and stiff so that they will stay in place in poor weather conditions, making them extremely useful in high seismic locations in order to dampen and move any seismic forces when they appear.

Equipment stands are specially made stands used to store equipment and can come in various forms, such as switch stands, lightning arrestors, coupling capacitor voltage transformer stands, current transformer stands and potential transformer stands.

Bus Supports are the most basic structure found inside a substation. Its main purpose is to provide support for rigid bus as it travels through the substation. Rigid bus is stiff and will not move around during weather events. Unlike rigid, flexible bus is typically used in high seismic areas in order to be able to move and dampen the seismic forces that occur.

Descriptions of our Products of Electrical Steel Substation Structures:

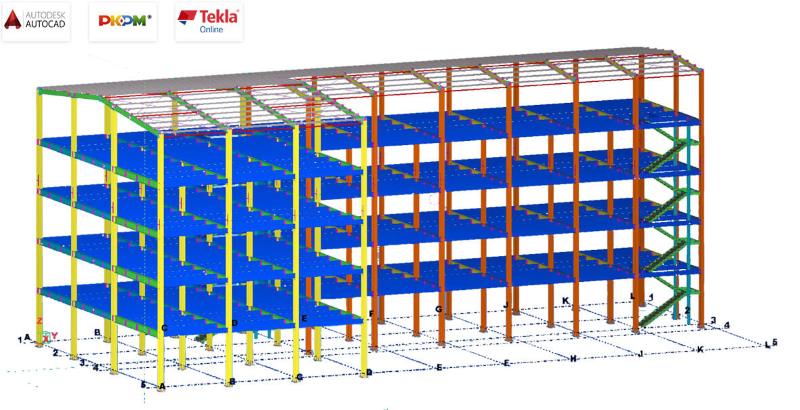

The substation structure has a rigid frame structure used to hang conductors, or support conductors, switch equipment, and other electrical equipment. ZHM Huawu Steel substations are divided into central substations, terminal substations, step-up transmission substations, step-down transmission substations, power system substations, mining operation substations, tower substations (27.5KV, 50HZ); substations with different voltage grades of 1000KV, 750KV, 500KV, 330KV, 220KV, 110KV, 66KV, 35KV, 10KV, 6.3KV, and other KV levels, 10KV small substations, and box type substations. We are also able to produce substation structures between 35 and 1,000KV.

ZHM Huawu Steel has exported a variety of substation structures to North America, Europe, Africa, other countries in Asia, and other locations. We have been engaged in this field for more than 20 years, and are experts at different substation structures. Our excellent design team, professional technical personnel, and experienced production staff can solve every problem that may arise during the production process.

ZHM Huawu Steel has professional testing equipment for quality control, and our strict production schedule ensures we are able to meet delivery deadlines. Delivery is traditionally 30 to 60 days depending on the order quantity.

If you do not have a product blueprint, we can design and produce the substation Steel structures to meet customer requirements, as well as produce samples and manufacture products according to drawings to satisfy their requests.

Why ZHM Huawu Metal Electrical Steel Substation Structures in Steel Works ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Electrical Steel Substation Structures in Steel Works ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com