High Rise Fire Simulator Training Building Liberia | Industrial Iron Ore Mines | ZHM,China Manufacturer Factory Supplier

High Rise Fire Simulator Training Building Liberia | Industrial Iron Ore Mines

Fire Simulator Structure for Training and Practical Assessment

1. Introduction:

The scope of work of this project including: designing, fabrication and constructing, and implementing a fire simulator structure tailored to the needs of a 15MTPA iron ore mining operation. The fire simulator and training platform will serve as a crucial training and practical assessment tool for emergency response teams and personnel.

The fire simulator building was made up of pre-manufactured and pre-assembled fixed modular training units to provide a complete installation of a modular training structure. The modular training structure was used to provide training for firefighters in a controlled simulated environment, which is commensurate with actual fire conditions. These specifications was used in conjunction with the drawings for dimensions, features, and exact configuration of the training structure. All components were new materials and designed specifically for the modular training tower.

Project Location: Yekepa, Nimba County and Buchanan,Grand Bassa County,Liberia,West Africa (CIF Freeport,Monrovia,Liberia

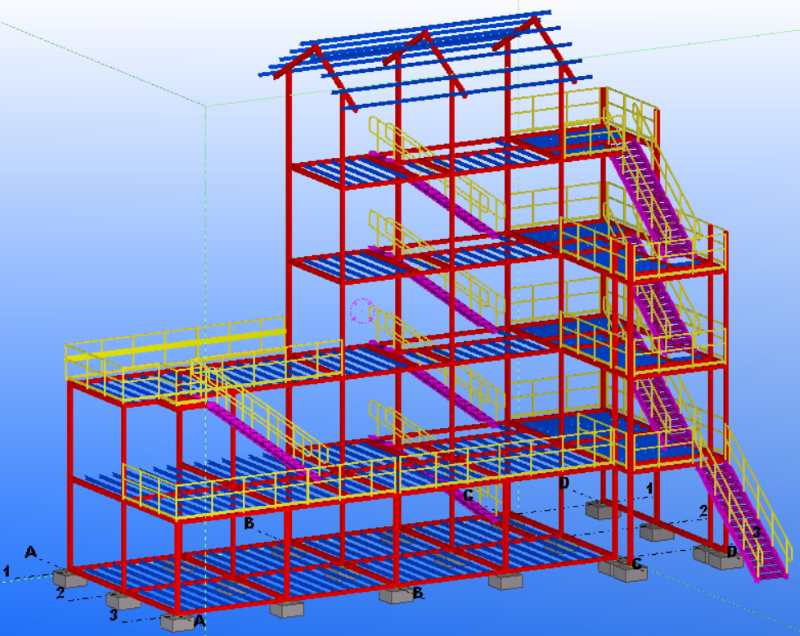

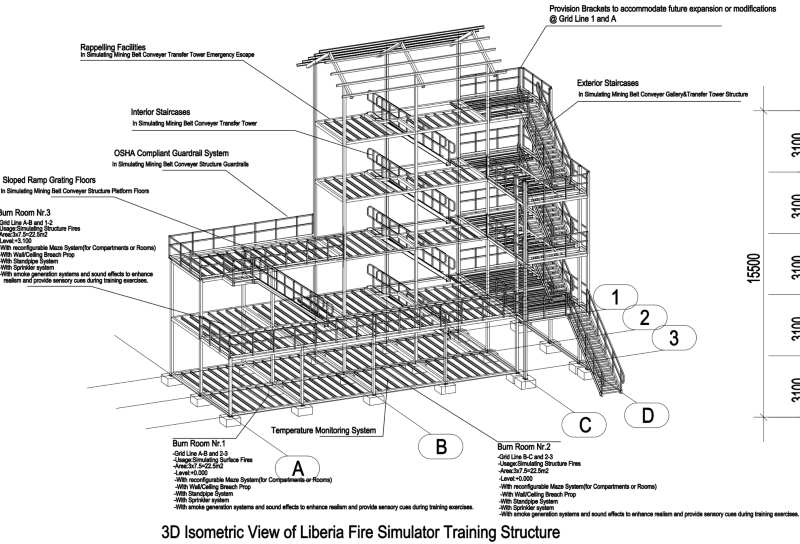

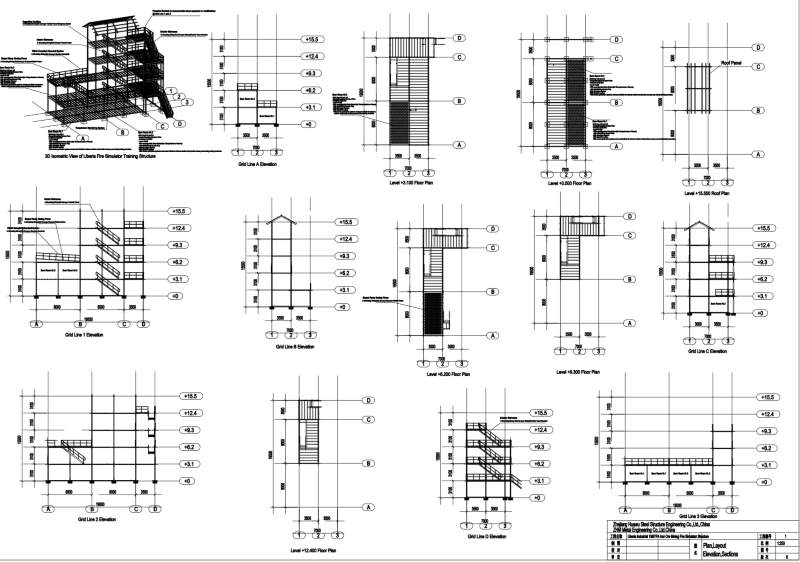

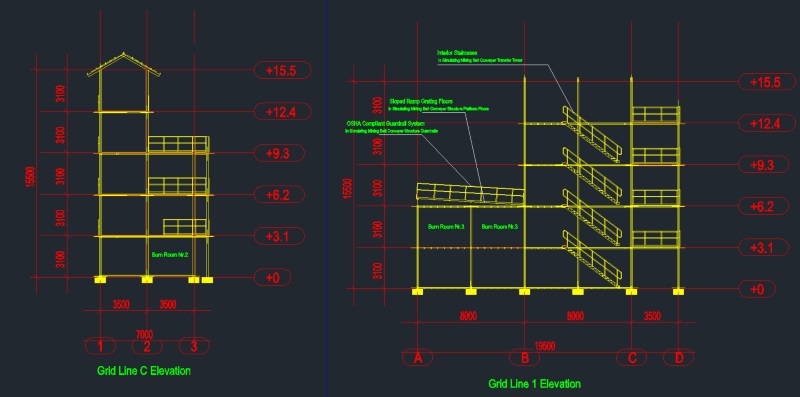

Building Size:

6-Storey, Overall Length=18.000m(center/center of columns)

Overall width=9.000m(Center/Center of columns)

Overall Height=18.000m(roof beam level)

Level 1: +0.000m (Ground Floor)

Level 2: +3.100m (1st Floor)

Level 3: +6.200m(2nd Floor)

Level 4: +9.300m(3rd Floor)

Level 5: +12.400m(4th Floor)

Level 6: +15.500m(5th Floor)

2. Objectives:

- Design, manufacture and construct a realistic fire simulator structure replicating various scenarios encountered in an iron ore mining environment.

- Provide a safe and controlled environment for training emergency response teams in fire suppression, evacuation procedures, and emergency management.

- Enable practical assessment of personnel competency in responding to fire emergencies, ensuring readiness and effectiveness in real-world situations.

- Incorporate features that simulate different types of fires, including those involving heavy machinery, equipment, and combustible materials commonly found in mining operations.

3. Key Features of this project:

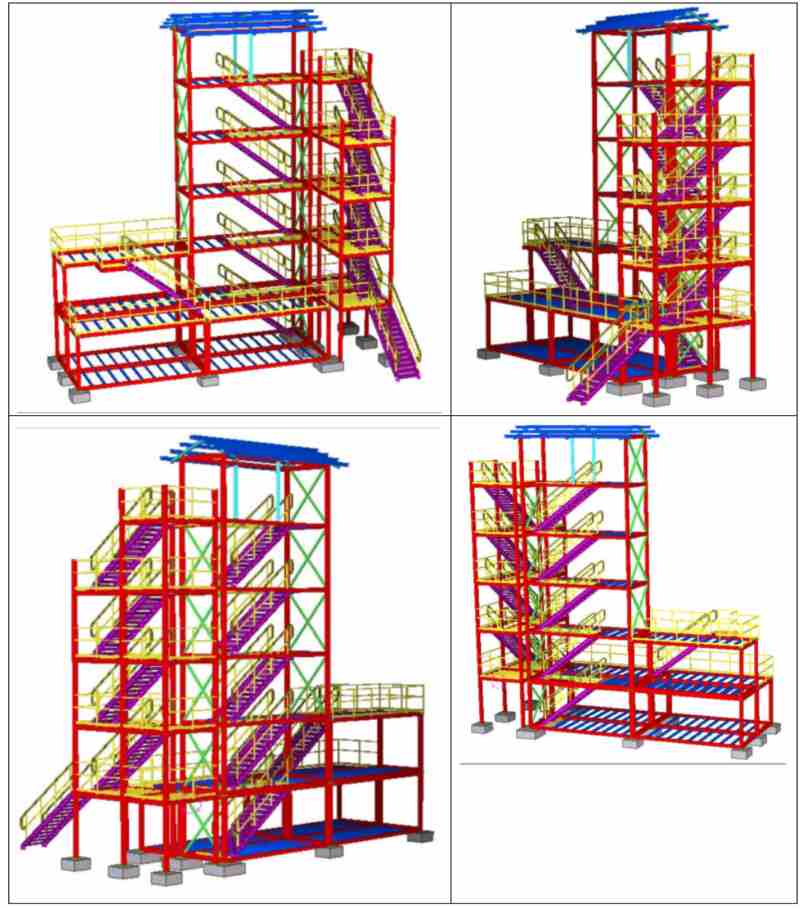

a. Design and Construction Requirements:

- The fire simulator structure was scalable and adaptable to accommodate future expansions or modifications at Grid Line A and 1 with bracket provisions .

- Utilize fire-resistant materials and construction techniques to ensure safety and durability.

- Incorporate realistic elements such as conveyor belts, storage facilities, and machinery to simulate the mining environment accurately.

- Include multiple compartments or rooms(ZHM Maze System) to simulate various fire scenarios, such as surface fires, equipment fires, and structure fires.

- Integrate smoke generation systems and sound effects to enhance realism and provide sensory cues during training exercises.

- Install a control panel to adjust fire intensity, smoke levels, and other parameters to customize training scenarios.

- Ensure accessibility and safety features such as emergency exits, fire extinguishers, and first aid stations within the simulator structure.

- Comply with relevant safety regulations, building codes, and industry standards throughout the design and construction process.

b. Deliverables from ZHM Huawu Steel:

- Construction schedule and milestones outlining key deliverables and timelines.

- Training curriculum and materials for emergency response teams and personnel.

- Documentation of training sessions, assessments, and performance evaluations.

- Maintenance and support plan for the ongoing operation of the fire simulator.

- Offer ongoing support and maintenance services to ensure the continued functionality and safety of the fire simulator structure.

- Conduct regular drills and simulations to familiarize emergency response teams with the simulator environment and evaluate their performance.

impact on operations.

2.2.References

A.International Building Codes - Current edition adopted by local authority

B. National Fire Protection Association (NFPA)

1. NFPA 1402-Guide to Building Fire Training Centers

2. NFPA 1403-Standard on Live Fire Training Evolutions

B.American Society for Testing and Materials (ASTM)

C.AWS D1.1-Structural Welding Code-steel

D.American institute of Steel Construction (AISC), Manual of Steel Construction, latest edition

F. Occupational Safety and Health Standards (OSHA)

1. 29 CFR 1910.23 – Guarding Wall and Floor Openings

2. 29 CFR 1910.24 – Fixed Industrial Stairs

3. 29 CFR 1910.27 – Fixed Ladders

2.3.Design Requirements

A.Structural Requirements

1. Provide fixed modular training structure system capable of withstanding the effects of gravity loads per NFPA 1402 and the following loads & stresses within the limits and under conditions specified by local code.

a. Wind Requirements:

1) Wind Load: Assumed 105 MPH Ultimate or per local code if required

2) Wind Exposure: Assumed C or per local code if required

b. Seismic Requirements:

1) Site Class: Assumed D or per local code if required

2) SS (Short Period) : Assumed maximum 10.9 or per local code if required

3) S1 (1-Second Period) : Assumed maximum 6.4 or per local code if required

c. Risk Category: I

d. Deflection Limits: Engineer primary & secondary framing components, floor systems, and wall assemblies to withstand design loads with deflections no greater than 1/240 of the span.

e. Exterior Wall Panel System:

1) The modular training structure exterior wall panels shall be a structural component of the design and provide shear and lateral loading as dictated by the design requirements.

f. Handrails and Guardrails per OSHA requirements:

1) Uniform load of 50 lb/ft applied in any direction

2) Concentrated load of 200 lbs applied in any direction

3) Uniform and concentrated loads need not be assumed to act concurrently.

B.Code Requirements

1. Structural design shall comply with the 2012 International Building Code for structural conformity.

2. Safety design shall comply with applicable OSHA requirements.

3. Training shall comply with applicable NFPA 1402 and NFPA 1403 requirements.

4. Due to the nature of the modular training systems and the intended use, egress and fire code requirements are not expected to satisfy code criteria for occupied buildings.

a. Local codes may require the simulator to have a variance due to the intended use and features unique to its application.

b. It is the responsibility of the owner or owner’s representative to determine the proper procedures and variances for their location and obtain the necessary variances or requirements.

2.3.Delivery, Storage, and Handling

A.All components and accessories necessary for the assembly of the simulator including modular floors, modular roofs, modular columns, modular stairs, modular doors, modular window shutters, and insulating material for burn rooms shall arrive at the project site by over-the-road trailer.

B. Store all modules and components according to storage instructions above ground,separated, and protected from exposure to the elements & from physical damage caused by other activities.

C. Maintain environmental conditions (temperature, humidity, and ventilation) within limits recommended by manufacturer for optimum results. Do not install products under environmental conditions outside manufacturer’s absolute limits.

|

SN |

Item |

Descriptions |

|

1 |

Structure Type |

Hot-dipped Galvanized Steel Rigid Frame columns/beams System |

|

|

1.a Windows |

12 single 900x1200windows 1 double window |

|

|

1.b Doors |

18 single doors 1 double door |

|

|

1.c. Stairs/Ladders |

6 storey interior stairs with intermediate ladings 6 storey exterior stairs 2 vertical ladders 1 bilco hatch 2 story interior star 2 story exteior stair |

|

2 |

Burn Rooms |

Refer to 2.4. 3Nrs of Padgenite Super Burn Rooms |

|

3 |

Temp Monitoring System |

Refer to 2.5. |

|

4 |

Shade canopy on Tower |

Refer to 2.6. Shade canopy structure and Annex Working Surface Platform on Tower

|

|

5 |

Rappelling Anchors |

8Nrs, refer to 2.7. |

|

6 |

Cantilevered Rappelling Platform |

8Nrs, refer to 2.7. |

|

7 |

Standpipe |

Refer to 2.8. |

|

8 |

Sprinkler System |

Refer to 2.9. |

|

9 |

Roof System |

Refer to 2.10.Half Flat/Half Parapet for training |

|

10 |

Exterior balcony |

Refer to 2.11. |

|

11 |

Floor Door&Window System |

Refer to 2.12. |

|

12 |

Drywall Knock Outs |

|

|

13 |

Movable Maze System |

Refer to 2.13. (Optional) |

|

14 |

Burn Cribs |

Refer to 2.14. |

|

15 |

Breaching |

Refer to 2.15. |

|

16 |

Confined Spaces (Optional) |

Refer to 2.16. |

|

17 |

Elevator Shaft (Optional) |

Refer to 2.17. |

|

18 |

Exhaust Fan |

Refer to 2.18. |

|

19 |

Hazmat Props |

Refer to 2.19. |

|

20 |

Ladders/Staircases |

Refer to 2.20. |

|

21 |

Simulators |

Refer to 2.21. |

|

22 |

Smoke Distribution System |

Refer to 2.22. |

|

23 |

Building Inspections |

Refer to 2.23. |

Why ZHM Huawu Steel High Rise Fire Simulator Training Buildings for Industrial Iron Ore Mines ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal High Rise Fire Simulator Training Buildings for Industrial Iron Ore Mines ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com