35kV Double Circuit Electricity Power Siingle Pole Tower Transmission Line

No Pics.

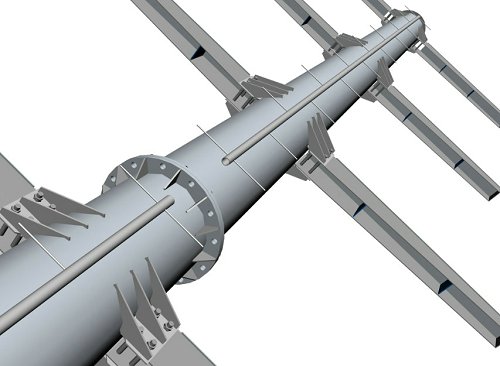

In power transmission line project, double circuit transmission line steel tower often used. For a double-circuit transmission line, which has two circuits, both tubular and lattice steel towers can be designed so as to support two circuits of electrical current. Double-circuit transmission towers hold the different conductors stacked atop one another, while in single-circuit towers the conductors are lined up horizontally.

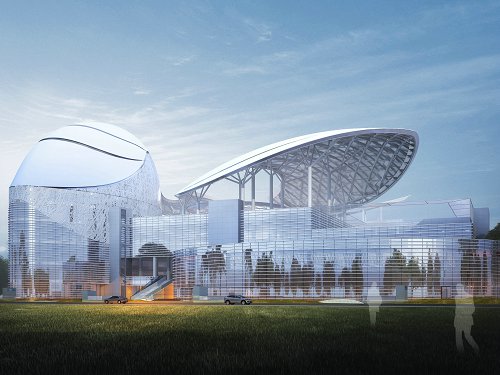

ZHM provide 35KV double circuit tangent transmission lines tower for our esteemed clients. The Tower Line work involves Survey, check survey, and span calculations essential for tower extensions. Moreover, Tower designs and prototype approval is done. 35KV power transmission line often use in urban power grid, even rural areas power grid, which belong to middle-voltage power transmission line. ZHM are experienced enough in design, fabrication, and installation cost effective range of 35KV power transmission line tower. Towers are processed through the facility by Caustic Cleaning, Pickling, and then Fluxing. High resistive galvanized steel is used in our manufacturing process to ensure high resistivity against heat, humidity, moisture, water etc. These strict procedures insure years of maintenance free towers. Moreover, ZHM ensure 35KV towers are delivers in varied design and technical specifications depending up on the nature of the applications in which these have to be used.

ZHM is one of the few manufactures who assemble a face of every tower section. This attention to quality may not be the cheapest process but it does insure every tower meets our high standards of quality. And it helps to reduce on-site construction cost due to mismatched assemblies.

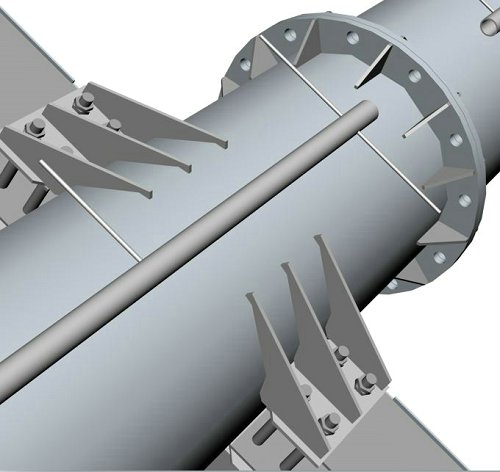

ZHM 35KV power transmission line Towers systems can accommodate a variety of cross-arm. ZHM also offers a wide variety of accessories and mounts.

Availability size: Based on the customer's requirements.

Material: Chinese material or as per clients requirement

Package: Both parties discuss before delivery

Terms of Payment: L/C, T/T

Minimum Order Quantity: 1 ton

Port of Loading: Qingdao Port

Lead Time: One month or based on the customer's needs

Performance Standard

Besides conform to the drawing and design, the materials and fabrication of tower components shall conform to the Chinese Standard or other standard which clients can accept.

Besides conform to the drawing and design, the materials and fabrication of tower components shall conform to the following standards (Chinese Standard or other standard):

1. GB/T2694-2003 Transmission line tower - - Technical requirements for manufacturing

2. JGJ81-2002: Technical specification for welding for steel structure of building

3. GB9787-88: Measuring and allowable tolerance for hot-rolled equal angle

4. GB709-88: Measuring and allowable tolerance for hot-rolled plate and strip

5. GB/T699-1999: Quality Carbon Structural Steel

6. GB/T1591-1994: Low alloy high strength structural Steel

7. GB700-88: Carbon Structural Steel

8. GB222-84: Method of sampling steel for determination of chemical composition and permissible variations

9. GB/T228-2002: Method for Tensile testing of metals

10 GB/T232-1999: Method for Bending test of metals

11 GB/T5117-1995: Carbon Welding Rod

12 GB/T5118-1995: Low Alloy Welding Rod

13 GB/T8220-1995: Welding wires for gas shielding arc welding of carbon and low alloy steels

14 GB/T10045-2001: Carbon steel flux cored electrodes for arc welding

15 JB/T7949-1999: Weld outer dimensions for steel construction

16 GB50205-2001: Test Standard for Acceptance of Steel Structure

17 GB/T470-1997: Zinc Ingot

18 GB3098.1-2000: Mechanical properties of fasteners-Part 1: Bolts, screws and studs

19 GB3098.2-2000: Mechanical properties of fasteners-Part2: Nuts, and thread

20 GB3098.3-2000: Mechanical properties of fasteners-Part3: Fastening screw

21 GB/T5780-2000: Helical Bolts Grade C

22 GB/T41-2000: Helical Nuts Grade C

23 GB/T90-2002: Flat Washer Grade C

24 GB/T13912-2002: Metal Coating, Technical Requirement

25. BS/EN 1461: Hot-dipped galvanization

We also adopt British, American and other international standard which client can accept.

| Name | Straight Line Pole | Tension pole | Corner Hole | |||||||||

| 30° | 60° | 90° | ||||||||||

| Type | 35SZG-12 | 35SZG-21 | 35SZG-21 | 35SZG-21 | 35SZG-12 | 35SZG-21 | 35SZG-12 | 35SZG-21 | 35SZG-12 | 35SZG-21 | ||

| Nominal height | 12 | 21 | 12 | 21 | 12 | 21 | 12 | 21 | 12 | 21 | ||

|

Applicable Conditions |

Conduct Cable |

Type | LGJ-185 | LGJ-185 | LGJ-185 | LGJ-185 | LGJ-185 | LGJ-185 | LGJ-185 | LGJ-185 | LGJ-185 | LGJ-185 |

| Safety Factor | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | |||

|

Grounding Cable |

Type | GJ-35 | GJ-35 | GJ-35 | GJ-35 | GJ-35 | GJ-35 | GJ-35 | GJ-35 | GJ-35 | GJ-35 | |

| Safety Factor | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | |||

| Horizontal Span(m) | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | ||

| Vertical Span(m) | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | ||

| Maximum Wind Speed(m/s) | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | ||

| Maximum Covered Ice(m/s) | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | ||

| Pole Type Data | Total Height(m) | 20 | 29 | 20 | 29 | 20 | 29 | 20 | 29 | 20 | 29 | |

|

Pole Top (side to side mm) |

250 | 250 | 260 | 260 | 280 | 260 | 320 | 320 | 360 | 360 | ||

|

Pole Bottom (side to side mm) |

450 | 620 | 620 | 720 | 850 | 800 | 840 | 960 | 920 | 1050 | ||

| Cross Arm Bracket Distance | H1(mm) | 1500 | 1500 | 1500 | 1500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | |

| H2(mm) | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | ||

| H3(mm) | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | ||

| Cross Arm Bracket Length | L1(mm) | 500 | 500 | 500 | 500 | 700 | 700 | 900 | 900 | 1000 | 1000 | |

| L2(mm) | 700 | 700 | 900 | 900 | 1000 | 1000 | ||||||

| L3(mm) | 1500 | 1500 | 1500 | 1500 | 1800 | 1800 | 2100 | 2100 | 2400 | 2400 | ||

| L4(mm) | 1500 | 1500 | 1400 | 1400 | 1200 | 1200 | ||||||

| L5(mm) | 1700 | 1700 | 1700 | 1700 | 2000 | 2000 | 200 | 2300 | 2600 | 2600 | ||

| L6(mm) | 1700 | 1700 | 1600 | 1600 | 1400 | 1400 | ||||||

| Anchor Bolts | 12-M27 | 12-M27 | 12-M30 | 12-M30 | 12-M36 | 12-M36 | 16-M39 | 16-M39 | 16-M42 | 16-M42 | ||