Interlock Type Calcium Silicate Tiles for Burn Room Thermal Lining Panels | Fire Simulator Towers for Training

Interlock Type Calcium Silicate Tiles

for Burn Room Thermal Lining Panels | Fire Insulator Towers for Training

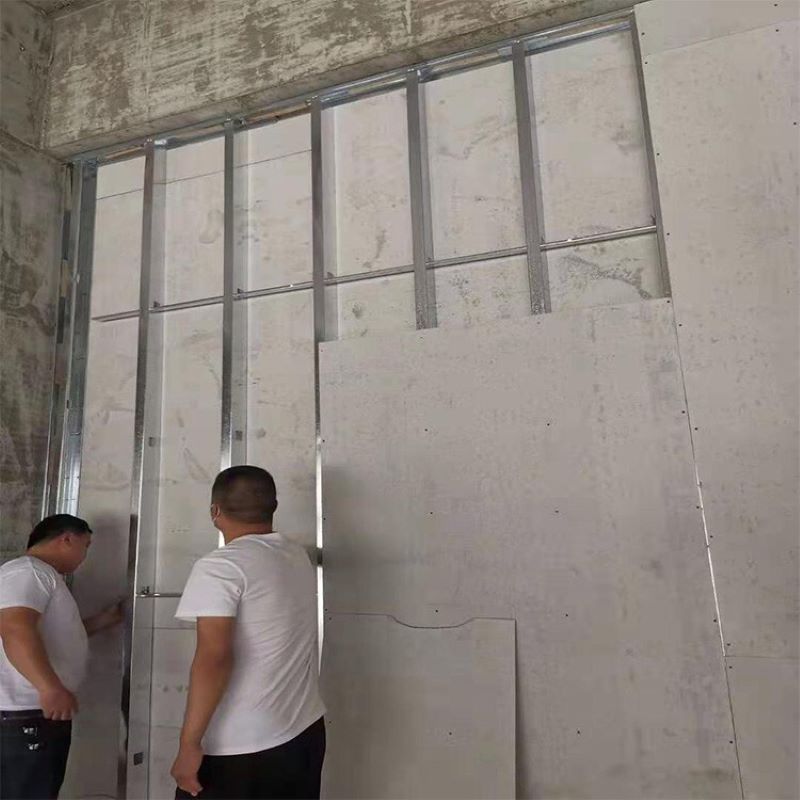

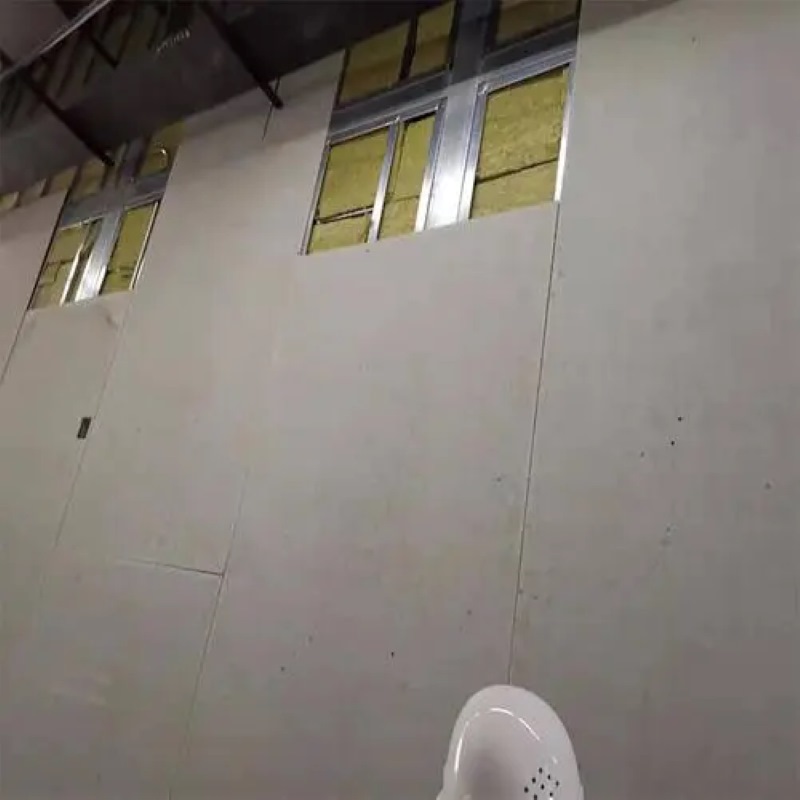

Interlock Type Calcium Silicate Burn Room Thermal Panels combines modern technology with a proven raw material to tackle today’s demands of tomorrow’s firefighters.

Performance Specifications of Interlock Type Calcium Silicate Burn Room Thermal Panels

| Design Property | Technical Data | Specification | Why is it Important? |

| Continuous Service Temperature | 1,700°F | ASTM C656 | Overdesigned continuous temperature provides a high safety factor for firefighter training environments |

| Thermal Transfer Flexible Air Gap 1.5”/3” | 334°F/238°F | Heat Exposure to Structure @1,000°F ASTM C680 | Maintain compliance with NFPA 1402 protecting all structural surfaces from 350°F with flexible air gap |

| Impact Resistance | 4,000 psi | Compressive Strength | The compressive strength combined with a tight 15” framing span means this has the highest impact resistance on the market |

| Durability | 80 | Surface Hardness – Shore “D” Scale (1-100) | With the highest surface hardness on the market Interlock boasts the best long-term resistance to wear, abrasion, and hose streams |

Panel vs Tile

Key Measurables of a Thermal Lining System

Interlock Tile vs Refractory Tile

Key Measurables of a Thermal Lining System

Interlock: A novel solution protecting structures; protecting people.

Why ZHM Huawu Metal Calcium Silicate Tiles for Burn Room Thermal Lining Panels | Fire Insulator Towers for Training ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Calcium Silicate Tiles for Burn Room Thermal Lining Panels | Fire Insulator Towers for Training ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com