Steel Wall Formwork Column Formwork Beam&Slab Formwork and Modular Formwork

2024-3-5 12:10:43

No Pics.

Introduction

Steel Wall Formwork Column Formwork Beam&Slab Formwork and Modular Formwork

As a trusted structural use concrete metal frame formwork supplier, ZHM Steel/metal formwork mainly contains Steel Formwork, Frame Wall Formwork, Steel Deck Slab Formwork, Adjustable Steel Frame Column Formwork, Steel Column Formwork and Single Side Formwork.

Advantages of Steel Formwork for Concrete

Steel formwork can save costs and bring environmental benefits to the construction process.

Creating steel formwork requires a minimal production process. There are many ways to make steel, one of which is computer modelling. The digital modelling process ensures that the steel is formed correctly the first time it is created and formed, thereby minimizing rework. If the steel formwork can be manufactured quickly, the speed of fieldwork will also be accelerated.

Due to its strength, steel is suitable for extreme environments and severe weather conditions. Its anti-corrosion performance reduces the possibility of accidents for building builders and residents, thus providing a safe environment for everyone.

Thanks to the reusability and recyclability of steel, metal formwork can be regarded as a sustainable building material. Therefore, more and more companies are making sustainable development choices to reduce environmental damage.

Why choose ZHM form as Concrete Metal Frame formwork Supplier?

ZHM form is a preferred supplier of concrete metal formwork for several reasons.

Firstly, we are known for delivering high-quality products.

Our formwork systems use durable and reliable materials, ensuring strength, stability, and longevity in construction projects.

We offer a wide range of customization options.

We can tailor the formwork systems according to specific project requirements, including dimensions, shapes, and design specifications.

ZHM form possesses extensive expertise and experience in the field of concrete formwork.

Our team of professionals understands the complexities of construction projects and provides valuable guidance and support throughout the process, ensuring optimal results.

In summary, ZHM form stands out as a concrete metal formwork supplier

due to its commitment to delivering high-quality, customizable, cost-effective, timely, and sustainable solutions supported by expert customer support.

Types of Steel Formwork

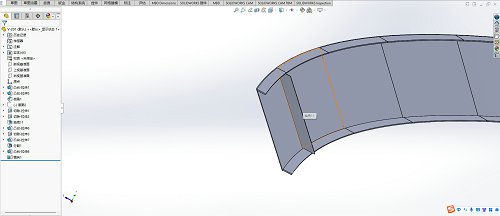

ZHM Frame Wall Formwork

ZHM Frame Wall Formwork

ZHM frame is a steel frame panel system lined with 12mm film-faced-plywood

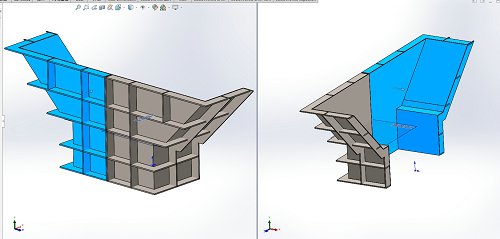

ZHM Adjustable Frame Column Formwork

ZHM Adjustable Frame Column Formwork

ZHM Adjustable Frame Column formwork is a steel frame panel system.

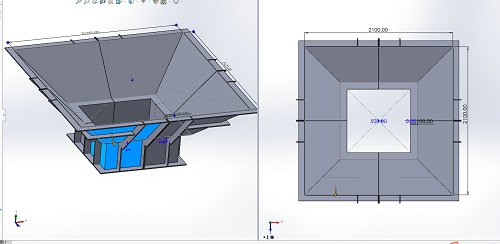

ZHM Single Side Wall Formwork

ZHM Single Side Wall Formwork

ZHM single side formwork is a standard formwork supporting bracket system

Where is steel formwork used?

Steel formwork manufactured by formwork manufacturers is used in construction projects, especially in large-scale and high-rise buildings.

It provides a temporary structure or mold to shape and support freshly poured concrete until it hardens and gains sufficient strength.

Some specific applications of steel formwork produced by concrete metal frame formwork suppliers include:

High-rise building construction often uses steel formwork, such as skyscrapers,

where it can withstand the pressure exerted by the weight of concrete at greater heights.

In the construction of bridge projects, such as piers, abutments, and other components,

steel formwork provides a stable and rigid structure that can support the weight of the bridge deck and withstand various forces.

For the structures like tunnels, underground chambers, and other subterranean structures,

it helps create the desired shape and provides support during concrete pouring.

Steel formwork finds application in the construction of industrial facilities, such as factories,

warehouses, power plants, and refineries. It allows for the efficient and precise casting of concrete to meet the specific requirements of these structures.

For the construction of water tanks, reservoirs, dams, and other water-retaining structures,

the steel formwork system ensures the integrity and strength of these structures, enabling them to hold large volumes of water without leakage.

For various infrastructure projects, including roads, highways, tunnels, and underground passages,

As a trusted structural use concrete metal frame formwork supplier, ZHM Steel/metal formwork mainly contains Steel Formwork, Frame Wall Formwork, Steel Deck Slab Formwork, Adjustable Steel Frame Column Formwork, Steel Column Formwork and Single Side Formwork.

Advantages of Steel Formwork for Concrete

Steel formwork can save costs and bring environmental benefits to the construction process.

Creating steel formwork requires a minimal production process. There are many ways to make steel, one of which is computer modelling. The digital modelling process ensures that the steel is formed correctly the first time it is created and formed, thereby minimizing rework. If the steel formwork can be manufactured quickly, the speed of fieldwork will also be accelerated.

Due to its strength, steel is suitable for extreme environments and severe weather conditions. Its anti-corrosion performance reduces the possibility of accidents for building builders and residents, thus providing a safe environment for everyone.

Thanks to the reusability and recyclability of steel, metal formwork can be regarded as a sustainable building material. Therefore, more and more companies are making sustainable development choices to reduce environmental damage.

Why choose ZHM form as Concrete Metal Frame formwork Supplier?

ZHM form is a preferred supplier of concrete metal formwork for several reasons.

Firstly, we are known for delivering high-quality products.

Our formwork systems use durable and reliable materials, ensuring strength, stability, and longevity in construction projects.

We offer a wide range of customization options.

We can tailor the formwork systems according to specific project requirements, including dimensions, shapes, and design specifications.

ZHM form possesses extensive expertise and experience in the field of concrete formwork.

Our team of professionals understands the complexities of construction projects and provides valuable guidance and support throughout the process, ensuring optimal results.

In summary, ZHM form stands out as a concrete metal formwork supplier

due to its commitment to delivering high-quality, customizable, cost-effective, timely, and sustainable solutions supported by expert customer support.

Types of Steel Formwork

ZHM Frame Wall Formwork

ZHM Frame Wall Formwork

ZHM frame is a steel frame panel system lined with 12mm film-faced-plywood

ZHM Adjustable Frame Column Formwork

ZHM Adjustable Frame Column Formwork

ZHM Adjustable Frame Column formwork is a steel frame panel system.

ZHM Single Side Wall Formwork

ZHM Single Side Wall Formwork

ZHM single side formwork is a standard formwork supporting bracket system

Where is steel formwork used?

Steel formwork manufactured by formwork manufacturers is used in construction projects, especially in large-scale and high-rise buildings.

It provides a temporary structure or mold to shape and support freshly poured concrete until it hardens and gains sufficient strength.

Some specific applications of steel formwork produced by concrete metal frame formwork suppliers include:

High-rise building construction often uses steel formwork, such as skyscrapers,

where it can withstand the pressure exerted by the weight of concrete at greater heights.

In the construction of bridge projects, such as piers, abutments, and other components,

steel formwork provides a stable and rigid structure that can support the weight of the bridge deck and withstand various forces.

For the structures like tunnels, underground chambers, and other subterranean structures,

it helps create the desired shape and provides support during concrete pouring.

Steel formwork finds application in the construction of industrial facilities, such as factories,

warehouses, power plants, and refineries. It allows for the efficient and precise casting of concrete to meet the specific requirements of these structures.

For the construction of water tanks, reservoirs, dams, and other water-retaining structures,

the steel formwork system ensures the integrity and strength of these structures, enabling them to hold large volumes of water without leakage.

For various infrastructure projects, including roads, highways, tunnels, and underground passages,

it provides a robust and reliable solution for shaping and supporting concrete elements.