Shore Bridging Trestle Jetty Steel Structures | Moma Sands Dolphin Piles ,Mozambique

Shore Bridging Trestle Jetty Steel Structures | Moma Sands Dolphin Piles ,Mozambique

Location : Mozambique

Year : 2016

Tonnage : 1400tons

Anti-corrosive Painting System: Special Graphene Waterborne Epoxy Anticorrosive Coatings were applied on the prefabricated Jetty Steel Structures for superior grade of anti-corrossion protection in salty-sea water environment.

Steel Materials Applied:The pipe diameters ranged from 914mm and 1778mm all at 25mm thickness. Lengths also varied between 4.0m up to 19.398m. Steel grades utilised included S355J2+N (including Z35 through thickness), S420M and S460M.

Connection Type: The design incorporated 4 grouting pipes spanning the from top all the way to a different set of levels, a series of internal and external shear rings and temporary padeyes for safe lifting with a project specific spreader beam.

Fabricator qualifications required for this project included: CE certification, EN1011-1 & 2, EN 1090-2 (EXC3), EN 10029: alongside additional client requirements.

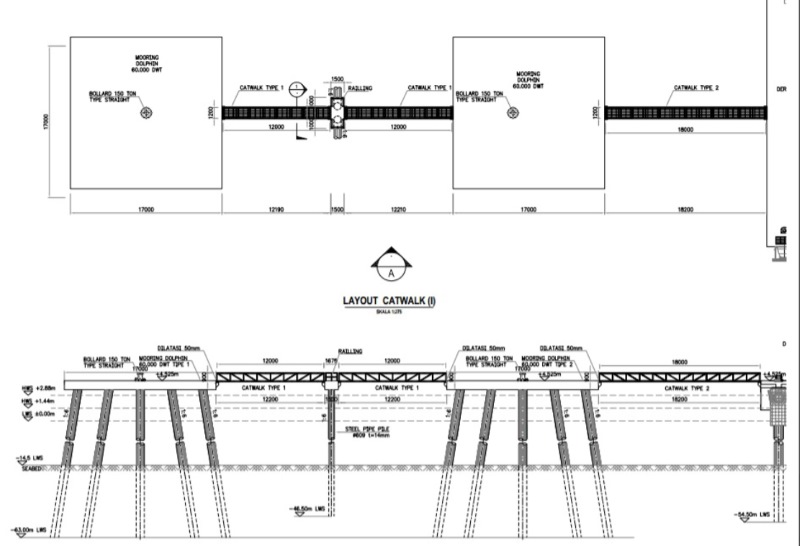

Project Photos of Shore Bridging Trestle Jetty Steel Structures | Moma Sands Dolphin ,Mozambique:

==============================

Extention of Knowledge:

What is a Jetty?

A jetty is a structure that extends from the shore into the water, and is typically constructed to protect a channel or harbor entrance from silting and erosion.

Jetties can be made from a variety of materials—including rock, concrete, steel or even a combination of materials.

The design of a jetty will depend on the specific location, the forces of waves and currents, and the intended application of the jetty.

Jetties are long, narrow structures that extend from the shore into the water. They can be categorized into various types based on their location, shape, and purpose. For example, entrance jetties protect harbor entrances from wave action, whereas channel jetties maintain a navigation channel in a river or harbor. Jetties can also be used for purposes like protecting beaches from erosion, providing a calm area for a marina, and enhancing recreational opportunities like fishing and boating.

The Different Types of Jetties

There are several different types of jetty designs available—each with their own specific uses and benefits, including:

Groin jetties: Groin jetties are short jetties that extend perpendicular to the shore and are typically used to reduce erosion and protect beaches.

Finger jetties: Often used in marinas, finger jetties extend from the shore and are used to create a protected area for boats and ships.

T-head jetties: T-head jetties extend from the shore and then turn at a right angle, forming a “T” shape. Because of their unique shape, T-head jetties are often used in ports and harbors to provide berthing and docking space for boats and ships.

Training jetties: Training jetties are longer jetties that are intended to guide and control the flow of water in a channel or harbor entrance.

Combination of jetties: Multiple jetties can be connected together in order to protect larger areas of shoreline from erosion and to provide multiple berthing and docking spaces for boats and ships.

Materials Used for Jetty Construction

The most common materials used for jetty construction include:

Rock: Natural rock—such as granite or limestone—is a durable and long-lasting material that can be used for larger jetty projects, as well as breakwaters.

Steel: Suitable for larger projects—such as ports or harbors—steel is durable and responds well to corrosive environments.

Concrete: Concrete is a versatile and durable material that is ideal for smaller jetty projects, as well as repairing and maintaining existing jetties.

Timber: Timber is a traditional material used for jetty construction that is inexpensive and easy to work with. That being said, timber is typically not be a suitable option for areas with strong waves or corrosive environments.

Recycled materials: Some jetties are even constructed using recycled materials, including—but not limited to—tires, plastic bottles, and other debris.

It’s important to note that the choice of material used for a jetty construction project will significantly depend on factors such as the location, the intended application of the jetty, and—of course—the budget.