Turbine Steam Air Cooling Island Steel Structure for Xinjiang Jinhui Power Plant China

Song Hu on October 23, 2014 - in Buildings, Design/Engineering, Feature, Featured, Structural components, Manufacturing, Fabrication, Delivery and Construction

Zhejiang Huawu Steel Structure(ZHM), an international engineering, contracting, manufacturing and construction company that is a leader in the specialized markets of steel structure buiilding and facilities for cooling systems, process heat exchangers, air quality systems, chimneys, and heat recovery steam generators and waste heat boilers. Xinjiang Jinhui Zhaofeng Energy Co. Ltd. retained ZHM to Design/Engineering, Feature, Featured, Structural components, Manufacturing, Fabrication, Delivery and Construction of the steel structure for the air-cooling island at the CNY 3 billion Xinjiang Jinhui Power Plant located in the Baicheng Heavy Chemical Industrial Park in Baicheng County, Xinjiang, China.

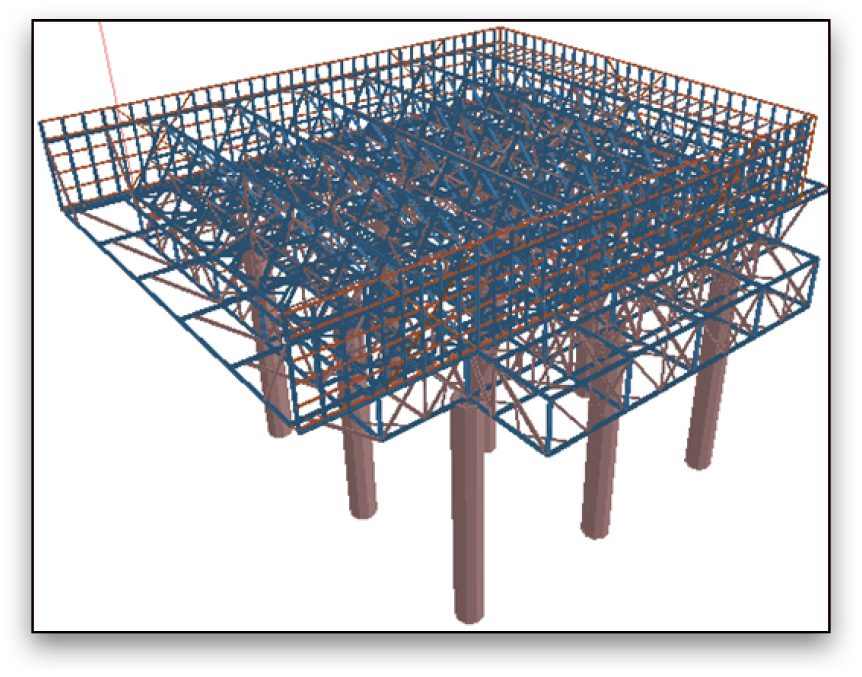

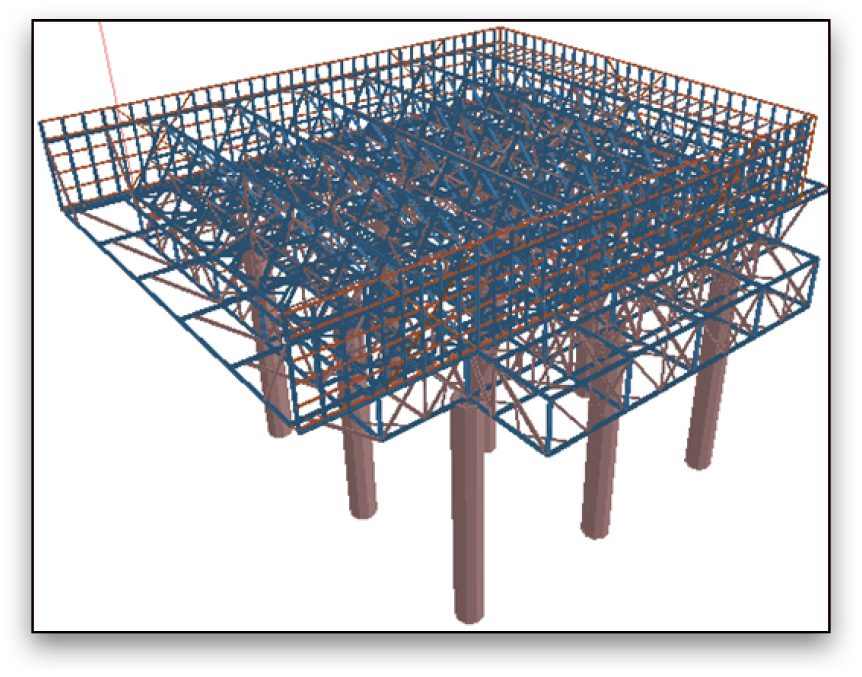

The air-cooling island will cool off steam produced by the turbines in 2×300 megawatt generator sets. ZHM made the BIM Modeling of the design of the steel structure took about 25 percent less time using STAAD.Pro, Bentley’s 3D structural analysis and design engineering software. STAAD.Pro enabled ZHM to optimize the design and decrease steel consumption from 3,500 tons to 3,100 tons. This represented a savings of CNY 2.5 million.

The 3D structural model in STAAD.Pro enabled structural engineers to perform load calculations and structural analysis within a unified model.

Multiple Load Calculations

Air-cooling islands use air as the medium for cooling off steam turbines. The designers of the Jinhui power plant specified a mechanical ventilation direct air-cooled condenser, which is a mature technology developed by ZHM/Jiashe Power Consortium . The technology includes environmental protection, energy saving, and water conservation features, and has been widely used in coal-fired power plants in China and around the world. For this project, each generator set contained 30 cooling modules, 30 electric motors and fans, 360 cooling pipe bundles, and associated gear cases and pipe systems.

The steel structure supporting the air-cooling system required a complex layout to accommodate the ductwork, pipes, and equipment. The steel platform itself was supported by a huge trussing system, with each generator set containing 7,000 irregularly arranged steel member bars. Construction of this massive steel structure required numerous falseworks, supporting pipe bundles, and ductwork systems. The design and budgeting of tendering had to consider the construction load to ensure the safety of the structure and construction workers. The standard method for calculating loads and forces called for simplification of the structure and separation into local parts, which would not provide an accurate analysis of the whole.

To optimize the design, engineerig of the steel structure and improve its safety and reliability, the ZHM/Jiashe Power project team chose STAAD.Pro. The software allows structural engineers to analyze and design virtually any type of structure through its flexible modeling environment, advanced features, and interoperability. The ZHM/Jiashe Power team used STAAD.Pro to build a uniform model that reflected the actual load and internal forces on each member bar. The model was used to perform analyses and calculations, then seamlessly transition the basic steel structure design into the detail design phase.Collaborative design and information sharing improved the overall efficiency of the design process.

STAAD.Pro enabled the design team to quickly resolve the complex modeling problems related to the air-cooling steel structure. ZHM/Jiashe Power designers were able to input the geometry of complex or existing structures, such as octagonal beams and pipe bundles, and perform necessary computations. The accurate results met Hamon’s requirements for holistic analysis of the internal force distribution.

“With STAAD.Pro, we can easily add load cases and design various load combinations. Therefore, we can fully consider construction conditions and design construction load and load combinations accordingly,” noted Yang Xiaobing, chief engineer

Time and Material Savings

STAAD.Pro greatly reduced the time required to define calculation parameters for the air-cooling steel structure. It also provided the flexibility to customize calculation parameters for more than 7,000 member bars. The ability to import data for collaborative design in other software applications facilitated modification of the structural model. Any modifications were easily shared among peers so that everyone had the updated version and no time was wasted on redundant modeling. Seamless transitioning among disciplines reduced the time for calculations from three weeks to three or four days, and the time for modeling from more than 400 man-hours to about 300 man-hours.

Because the design requirements for multiple load cases were considered, the designers were assured that the loads under construction conditions would be safely supported. Using the STAAD.Pro model, Hamon’s engineers were able to adjust and optimize the steel structure with confidence. As a result, steel consumption was decreased from 3,500 tons to 3,100 tons, saving more than CNY 2.5 million. The savings in time and materials helped to reaffirm ZHM/Jiashe Power’s place as a leader in the market for world-class cooling systems.

Would you like to see more images of Turbine Steam Air Cooling Island Steel Structure Buildings and Facilities ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 or send us your questions via email to info@zhmsteelworks.com