Prefabricated Stone Field Steel structure quarry workshop in Guangdong,China

Period of Project : May.2017

Product : Steel structure quarry workshop

Total Area : 3500㎡

Steel structure quarry workshop in ,China

Guangdong Group occupies an area of 600000 squire meters,

Measures to prevent dust generated by crushing stones is using the closed steel structure workshop made by ZHM. The gravel is mainly used for the processing of base-level bedding, highway engineering, airport reclamation and so on. The breaking production line is the leading technology in China with high productivity and high efficiency. The crushing site is close to the dock and the aggregate can be transported by a two-kilometer large conveyor belt to the transport ship.

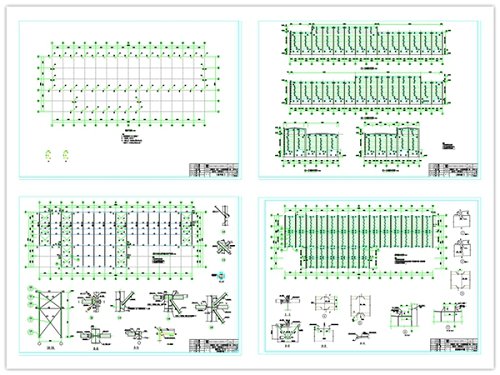

The overall design of the steel structure is particularly critical for the entire building. The design team of ZHM first designs the floor plan using CAD software in quarry workshop, then uses 3D software to model it, and the data is then modeled by the chief engineer. Analyze and contrast, design the scheme that suits the actual demand of the workshop most, make the steel structure workshop reach weatherproof, anti-vibration, closed production, prevent dust

With the concept of environmental protection and the sustainable development has become more and more in-depth, and the demand for low-cost and high-efficiency has become increasingly high in practical work. Steel structure construction causes little pollution during construction, and it is easy to install and disassemble, and can be 100% The advantages of recycling have also become more prominent. As an outstanding enterprise in the industry, ZHM will continue to update and optimize itself, improve its own professional and technical level, fully grasp the production and installation technology of steel structures, strengthen the control of steel structure production and installation quality, ensure the safety and quality of construction projects are good.

Quarry workshop wall installation

After designing and testing, in the case that the weight of the building is only one-fifth of the brick-concrete structure, it can withstand winds of 200 kilometers per hour and heavy rainstorms with a total of 12 hours of total rainfall of 100 millimeters. Quarry Steel Structure Workshop The seismic intensity is as high as 10, so that the life and property can be effectively protected, and the workshop production is not affected by the harsh environment. Compared to the traditional open-pit mining, the quarry steel structure workshop can provide a good environment for the production work. Closed-in production also has a powerful role in promoting the harmonious development of the ecological environment and the secondary use of waste resources. Closed production can effectively prevent the spread of dust, combined with core technologies such as biological nanofilm dust suppression technology, cloud dust suppression technology, and wet dust collection technology, to collect and process dust, and achieve low cost and high efficiency to reduce the pollution caused by mining work to the atmosphere.

Quarry workshop finish installation

In the Quarry Steel Structure Workshop project undertaken by ZHM prefabricated steel structure deep prefabrication construction technology is applied to the prefabrication of steel structures such as pipe frames and equipment platforms. Designed through 3D professional modeling, detailed to the connection position and bolt arrangement. The professional design team conducted a detailed technical investigation, eliminated the difficulties of prefabricated steel structures, multiple nodes, high design requirements, and short installation time, and completed efficiently all production difficulties. The prefabricated depth of all steel structures reaches 98%, and the tolerances of the axis lines, elevations, and joint positions of the system's pipe racks are controlled within 2mm, and there are no reworks beyond the millenium pipe racks. The hole position, aperture, quantity, etc. of several million bolts are matched with the field installation with no mistake.

- Pre:None

- Next:Prefabricated Stone Field Stee 2024/4/1