Air cooled heat exchanger for heat transfer processes in chemical, oil and gas, process and power generation

Air cooled heat exchanger for heat transfer processes in chemical, oil and gas, process and power generation

Thermal Designs Fully Customized to Your Project Specifications

Our ratings engineers understand the wide range of fluid applications, including hydrocarbons, glycol and water.

Proprietary computer models are used to optimize heat transfer surface and pressure drop.

Models are verified to meet or exceed Heat Transfer Research, Inc. (HTRI) thermal design standards.

Proven Mechanical Systems Available

Fans, belt drives, sheaves and other mechanical components are built for reliability and easy maintenance. Morotized fan and reducer may be specified.

Mechanical equipment is factory tested to meet thermal, vibration, noise and other performance specifications.

ZJPE Heat Exchangers are available in a range of materials and designs to meet your operational requirements.

Design Configurations:

Forced draft

Induced draft

Horizontal

Vertical

A-frame

Tube Metals and Alloys:

Carbon steel

Stainless steel

Duplex stainless steel

Copper

Copper nickel

Titanium

Inconel® and Incoloy®

Hastelloy® and other proprietary alloys

Fin Materials:

Aluminum

Copper

Hot-dipped galvanized steel (HDG)

Fin Tube Types:

“L” Footed

Extruded

Embedded (G-Fin)

Elliptical (Galvanized)

ZJPE Air Cooled Heat Exchangers stand up to the demanding requirements for heat transfer processes in chemical, oil and gas, process and power generation applications.

- Pre:Pratt Truss Aluminum Bridge Ve 2020/10/21

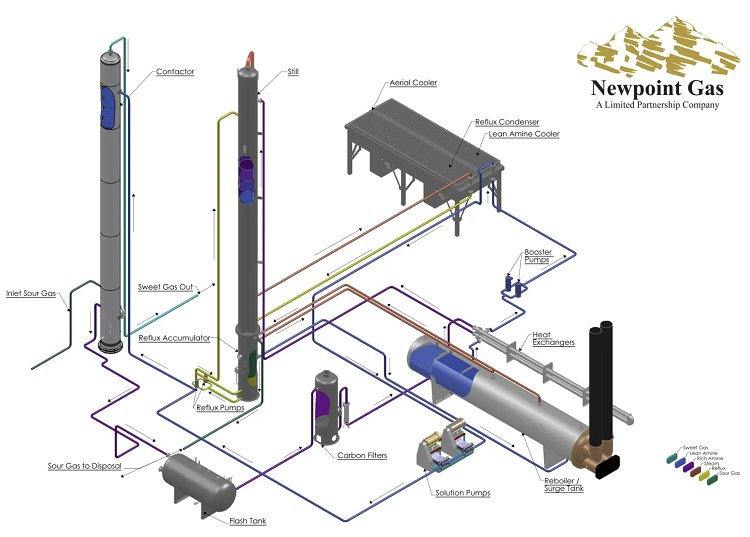

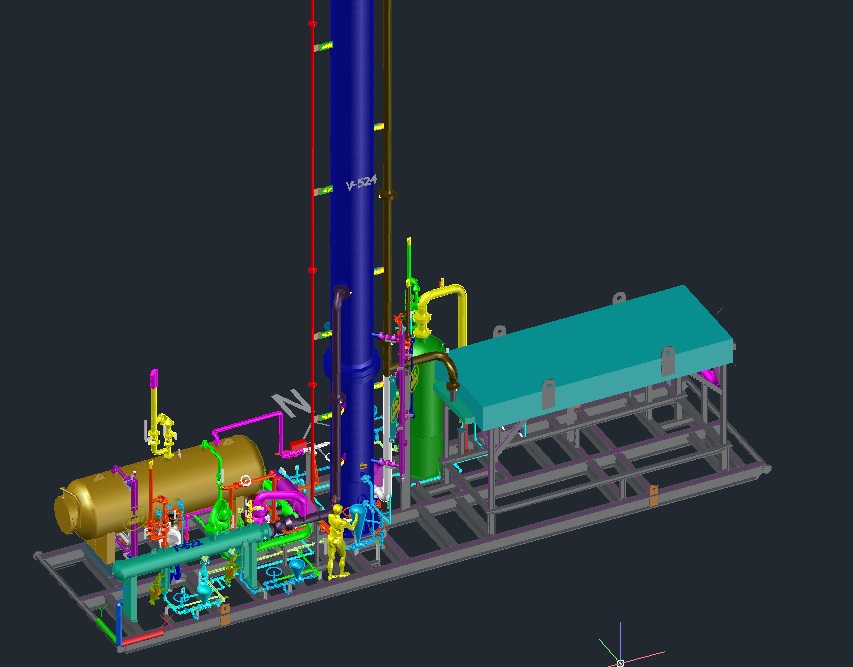

- Next:Amine cooler, reflux condenser 2020/5/10