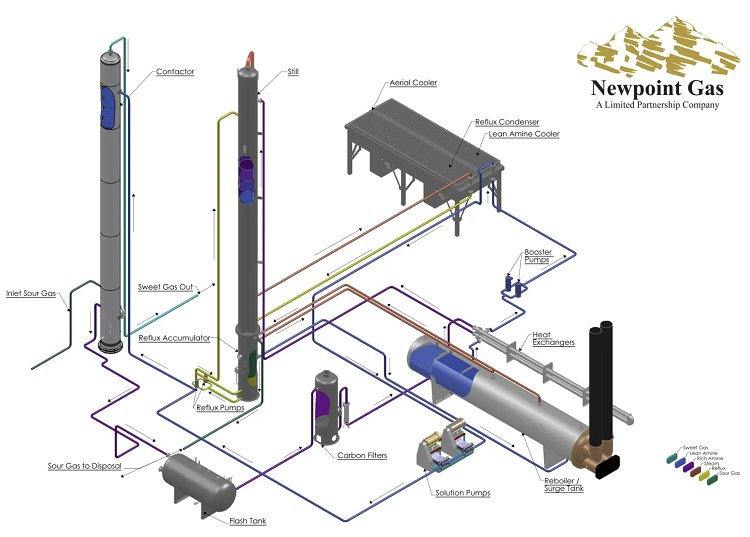

Amine cooler, reflux condenser and treated gas cooler heat exchanger

Amine cooler, reflux condenser air cooled heat exchanger for heat transfer processes

Amine cooler, reflux condenser and treated gas cooler heat exchanger

Design Basis:

Ambient temperature: 110/80 (Max/Min)

Relative Humidity; 30-70%

All the exchangers are equipped with VFDs, Vibration Switches, soft starters and louvers controls.

|

Sr. No. |

Exchanger Name |

Duty |

Remarks |

|

1. |

Amine Cooler |

-6.32 MMBTU/HR |

NOTE:Flow rate is adjusted in such a manner that the desired heat duties are achieved. |

|

2. |

Reflux Condenser |

-3.6710MMBTU/HR |

NOTE:Flow rate is adjusted in such a manner that the desired heat duties are achieved. |

|

3. |

Treated Gas Cooler |

-1.034 MMBTU/HR |

NOTE:Flow rates are adjusted in such a manner that the desired heat duties are achieved. |

|

AIR HEAT EXCHANGER SELECTION AND QUOTATION |

||||

|

Description |

Quantity |

Rate |

Total Price in USD |

|

|

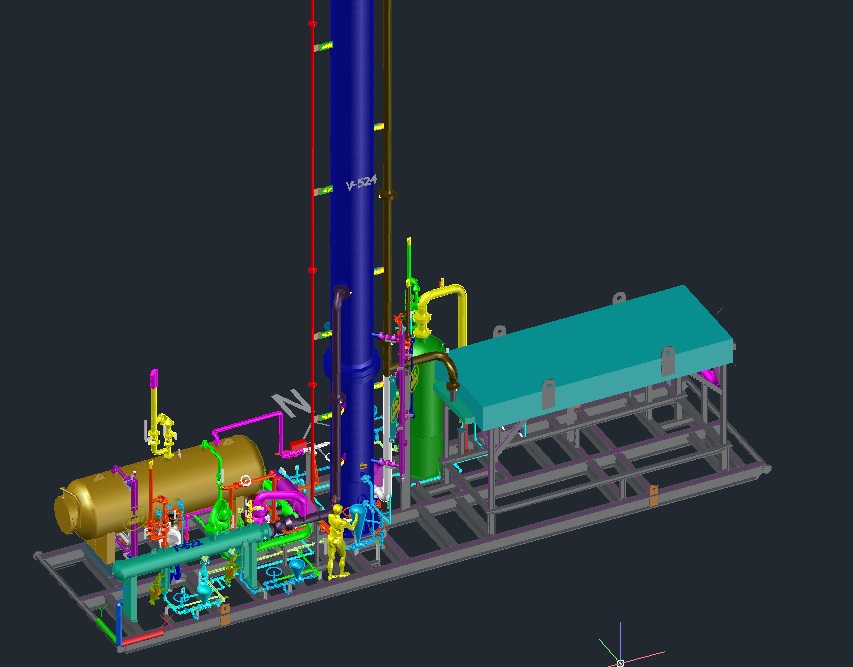

AMINE COOLER * Model No: 2-SZGL-10-48-6000 * Tag No: Amine Cooler(SK-AC-Amine) * Hot Side (Amine): Inlet85.5℃-Outlet54.45℃ Fluid flow(Inlet): 74570.4kg/h * Cold Side(Air): Inlet43.34℃-Outlet53.22℃ Fluid flow(Outlet): 660374.6m³/h Heating Exchange Surface Area: 6336㎡ Design Temp: Tube side 100℃ Design Pressure: Tube Side 1.0Mpa Shell Side: Normal Surface Tube Quantity=48x2 Pieces Tube Rows: 10 Rows Tube Spec: Heat exchanger tube¢25×2-50 316L SS tube with aluminium fin , Others Q345R Tube length: 6000mm Connecting tube diameter: DN65x2, air side open, The equipment to be divided into two separate ones and parallel connected. The price here exclude any insulation, fan, motor, reducer, louver or meter/valves,etc. Approximate weight: 18.072ton

|

|

|

|

|

|

Amine Cooler Frame structure HW175x175 with walking grating/handrails and ladders, Hot-dipped galvanized GJP14×5B-39/2F, H=3800, W=11.5T

|

|

|

|

|

|

Amine Cooler Motorized fan D=3900 G-39, qnty=2 set2 |

2 Set |

|

|

|

|

AIR COOLED REFLUX CONDENSER * Model No: 4-SG-30-30-6000 * Tag No: Reflux Cond.(SK-AC-Reflux.) * Hot Side (reflux): Inlet104.45℃-Outlet48.89℃ Fluid flow(Inlet): 71035.2kg/h * Cold Side(Air): Inlet43.34℃-Outlet51.67℃ Fluid flow(Outlet): 427492m³/h Heating Exchange Surface Area: 3052㎡ Design Temp: Tube side 100℃ Design Pressure: Tube Side Normal Shell Side: Normal Surface Tube Quantity=30x4 Pieces (2 Passes) Tube Rows: 30 Rows Tube Spec: Heat exchanger tube¢45×3-S30408 SS tube frame S30408 , Others Q345R Tube length: 6000mm, air side open, The equipment to be divided into four separate parts and parallel connected. The price here exclude any insulation, fan, motor, reducer, louver or meter/valves,etc. Approximate weight: 31.010ton

|

|

|

|

|

|

AIR COOLED TREAT GAS COOLER REFLUX CONDENSER * Model No: SG-32-55-5000 * Tag No: Treat Gas Reflux Cond.(SK-AC-TG) * Hot Side (reflux): Inlet62.11℃-Outlet48.89℃ Fluid flow(Inlet): 39189.6kg/h * Cold Side(Air): Inlet43.34℃-Outlet48.34℃ Fluid flow(Outlet): 93326m³/h Heating Exchange Surface Area: 880㎡ Design Temp: Tube side 100℃ Design Pressure: Tube Side Normal Shell Side: Normal Surface Tube Quantity=32x2 Pieces (Single Pass) Tube Rows: 32Rows Tube Spec: Heat exchanger tube¢32×2- tube grade 20#, 8 , Others Q345R Tube length: 5000mm, air side open, The equipment to be divided into four separate parts and parallel connected. The price here exclude any insulation, fan, motor, reducer, louver or meter/valves,etc. Approximate weight: 6.605ton

|

|

|

|

|

Thermal Designs Fully Customized to Your Project Specifications

Our ratings engineers understand the wide range of fluid applications, including hydrocarbons, glycol and water.

Proprietary computer models are used to optimize heat transfer surface and pressure drop.

Models are verified to meet or exceed Heat Transfer Research, Inc. (HTRI) thermal design standards.

Proven Mechanical Systems Available

Fans, belt drives, sheaves and other mechanical components are built for reliability and easy maintenance. Morotized fan and reducer may be specified.

Mechanical equipment is factory tested to meet thermal, vibration, noise and other performance specifications.

ZJPE Heat Exchangers are available in a range of materials and designs to meet your operational requirements.

Design Configurations:

Forced draft

Induced draft

Horizontal

Vertical

A-frame

Tube Metals and Alloys:

Carbon steel

Stainless steel

Duplex stainless steel

Copper

Copper nickel

Titanium

Inconel® and Incoloy®

Hastelloy® and other proprietary alloys

Fin Materials:

Aluminum

Copper

Hot-dipped galvanized steel (HDG)

Fin Tube Types:

“L” Footed

Extruded

Embedded (G-Fin)

Elliptical (Galvanized)

ZJPE Air Cooled Heat Exchangers stand up to the demanding requirements for heat transfer processes in chemical, oil and gas, process and power generation applications.

- Pre:Amine cooler, reflux condenser 2020/5/10

- Next:Elevated Steel Structure Tower 2020/4/11