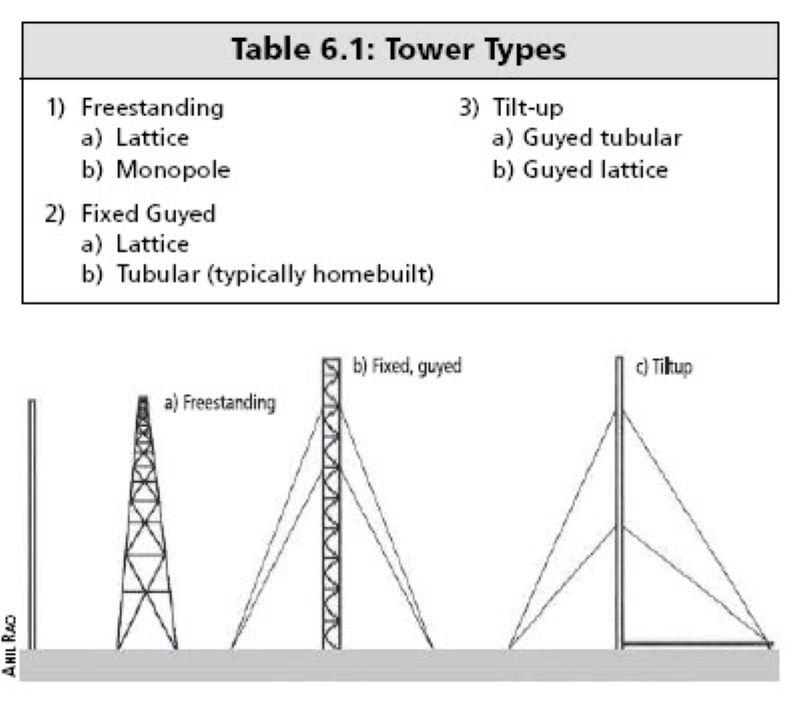

Why a guyed tower?

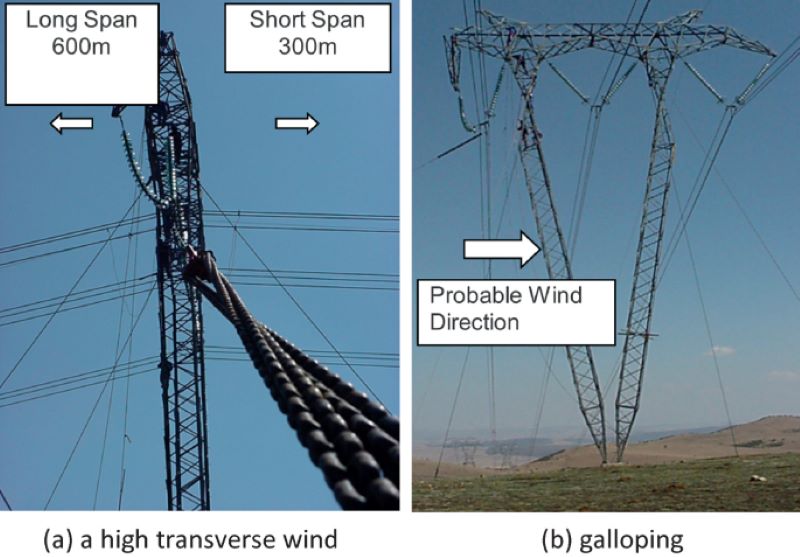

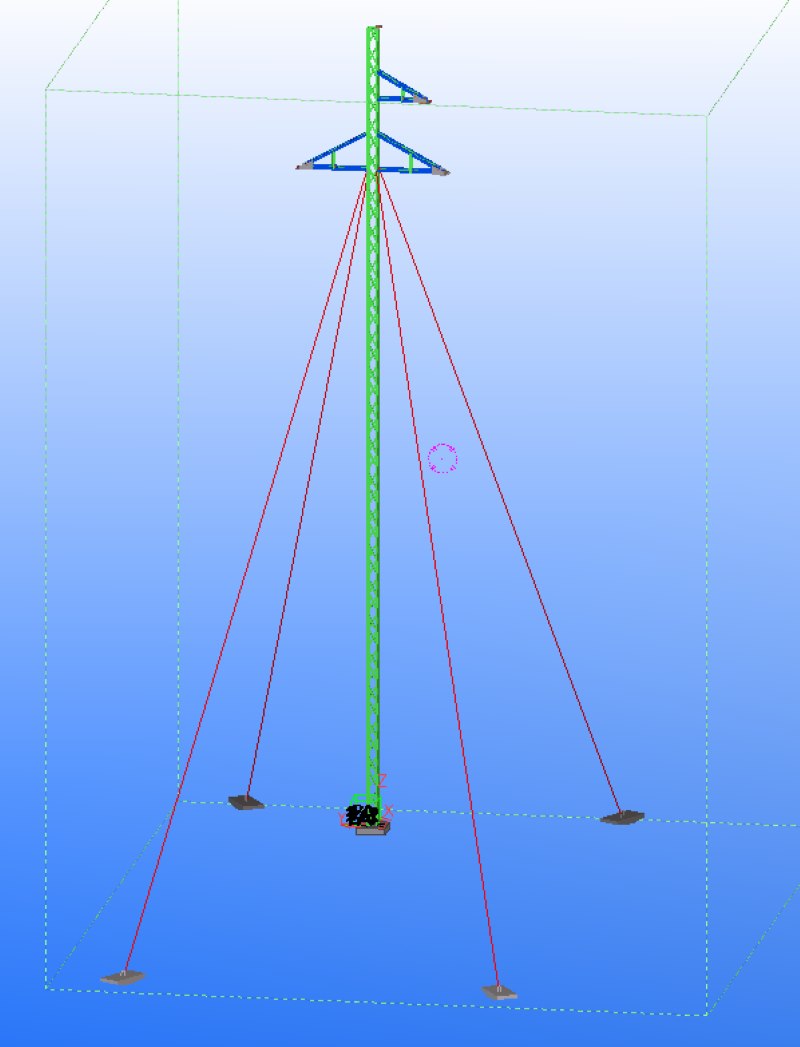

Guyed structures offer rigid support for technical equipment by providing minimal deflection. Taught guys transfer bending and twisting loads into vertical or axial loads culminating in a point load at the base. Due to this design feature, freestanding towers should never be guyed. Although you might be able to get away with it, it is a less than ideal engineering practice as converting a bending moment to a vertical load could cause failure. Adding guys to strengthen a structure might just have the opposite effect.

Although guyed towers have a larger footprint, it can provide significant cost savings where space and topography are not an issue. Less engineering, material, and fabrication is required when compared to a freestanding design. For the foundation, the low bending moment and high vertical load can greatly reduce civil work at the base. Although a guyed tower requires many foundations (the base plus one for each guy anchor), they are smaller and can be done without the use of heavy machinery. This is critical for remote locations where access can be an issue.

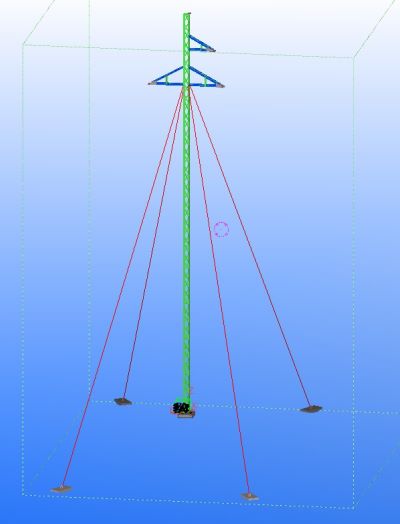

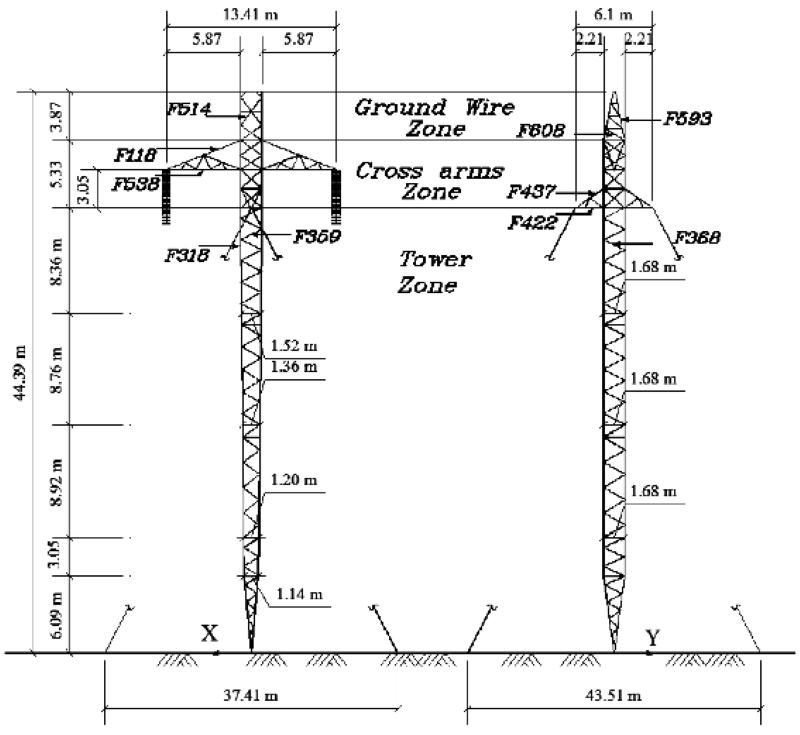

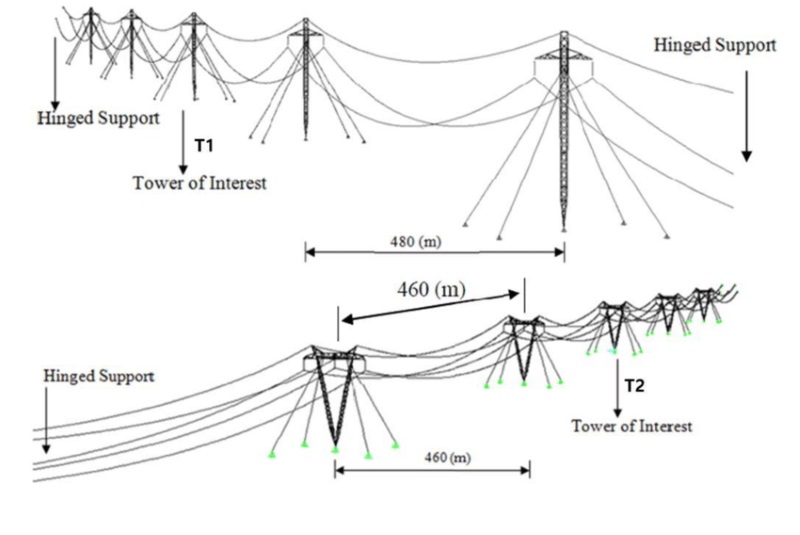

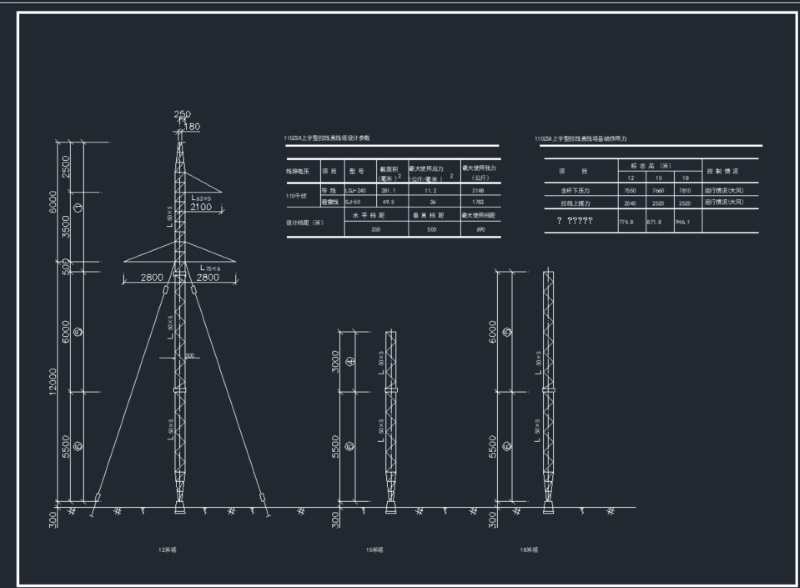

ZHM Huawu Steel provide Series 11kV/33kV/35kV/66kV/110kV/138KV/166kV/220kV typical guyed lattice suspension structure at a much lower material cost than self supporting towers due to the efficient use of steel guy lines, The guyed lattice masts are normally guyed in three or four directions equally spaced 120 degrees apart over an anchor radius of typically 2/3 of the tower height, The mast construction consists of triangular or square lattice modular section, each module fully welded tubular leg and solid round bar bracing incorporating integral step rungs fabricated into the lattice framework on one face this removes the need for a separate ladder. all masts sections are hot dipped galvanized after fabrication. Mast heights range 9 up to 50 meters, these masts can also be Etched primed and powder coated as an optional extra if required

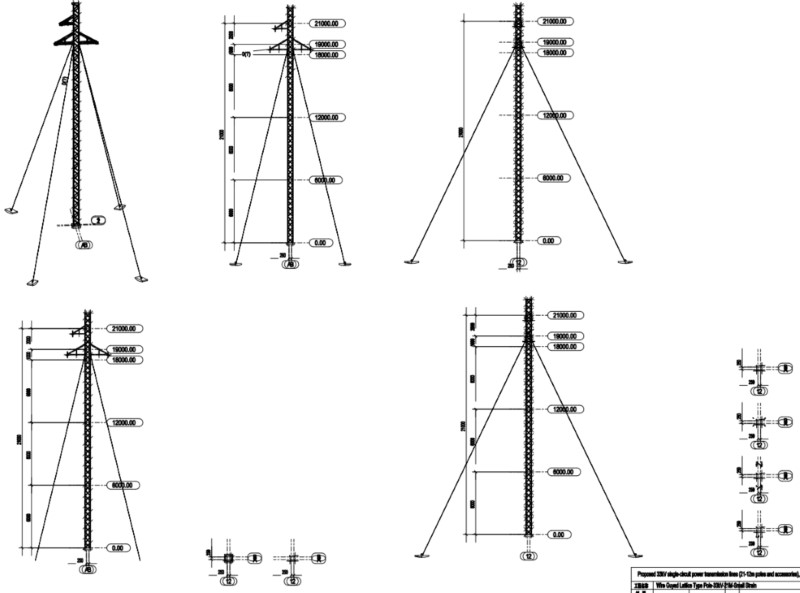

Since 2004, ZHM Huawu Steel has been manufacturing every type of lattice transmission tower & tapered steel poles for utility applications. ZHM Huawu Steel pioneered the development of transmission tower, telecom tower, substation, and other steel structure and was also at the forefront in the design of Transmission tower. ZHM Huawu Steel has a complete staff of professional engineering personnel trained in the PLS Pole program and three different manufacturing processes for producing steel towers, poles and other supports. We utilize the latest versions of PLS-CADD, PLS-POLE, TOWER, AutoCAD and other CAD software.

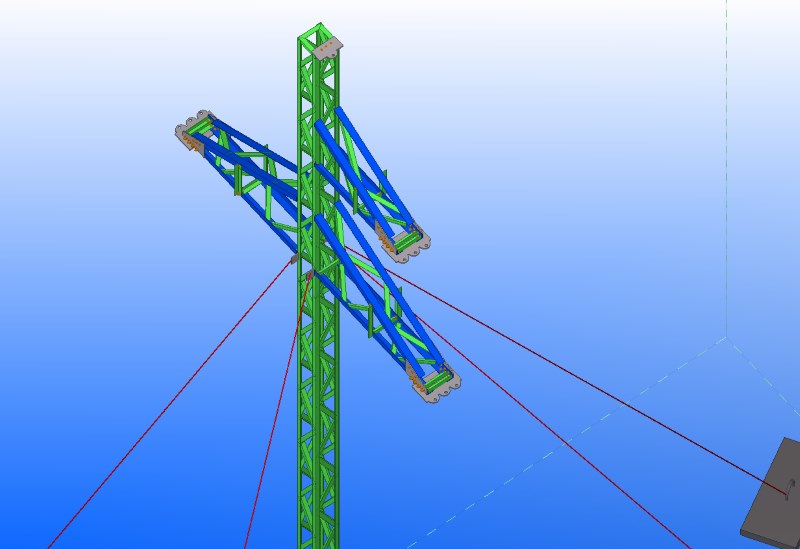

ZHM Huawu Steel is one of the few manufactures who assemble a face of 11kV/33kV/35kV/66kV/110kV/138KV/166kV/220kV typical guyed lattice suspension structure. This attention to quality may not be the cheapest process but it does insure every tower meets our high standards of quality. And it helps to reduce on-site construction cost due to mismatched assemblies.

ZHM Huawu Steel 138KV typical guyed lattice suspension structure systems can accommodate a variety of cross-arm and other accessories. After fabrication 138KV typical guyed lattice suspension structures are delivered to the galvanizing facility to be Hot DIP Galvanized. Towers are processed through the facility by Caustic Cleaning, Pickling, and then Fluxing. These strict procedures insure years of maintenance free towers. Even we take secondary finish for client again, which as duplex surface treatment.

Other information:

|

Availability size: |

Based on the customer's requirements. |

|

Material: |

Chinese material or as per clients requirement |

|

Package: |

Both parties discuss before delivery |

|

Port of Loading: |

Shanghai/Ningbo China |

|

Lead Time: |

One month or based on the customer's needs |

|

Minimum order: |

1 set |

|

Fabrication standard: |

Chinese Standard or other standard which client accepted |

Steel grades

|

tower body: |

Chinese steel Q345B, which same to ASTM A572 GR50 |

|

Other webs, bracing and not stress plate and angle steel: |

Chinese Q235B, which same to ASTM A36 |

|

Plates: |

Chinese steel Q345B, which same to ASTM A572 GR50 |

|

Bolts: |

Chinese grade 6.8 and 8.8, which similar to ASTM A394 |

|

Dimension and tolerance for angle |

according to GB/T1591-1994, similar to EN 10056-1/2 |

|

Hot DIP galvanization |

in accordance with GB/T 13912-2002, which similar to ASTM A 123 |

|

The welding |

will be performance in accordance with AWS D1.1 or CWB standard |

Why ZHM Huawu Metal Wire Guyed Lattice Towers | Suspension Poles | Power Transmission Lines ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Wire Guyed Lattice Towers | Suspension Poles | Power Transmission Lines ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com