Year: Sep-Nov.2022

Project partners: ACCIONA Ingeniería, ACCIONA Construcción, Ramboll, Nye Veier COWI, Statens Vegvesen

The route follows the old road, with the exception of the tunnels, which will run parallel to the existing ones.

From the multiple structures that conform the project ZHM Huawu Steel's scopes will focus on:

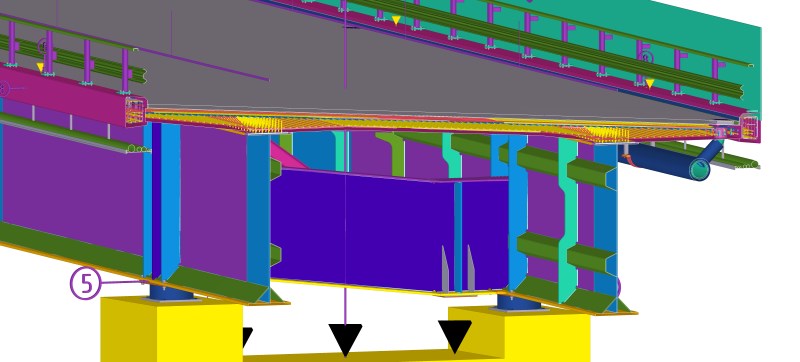

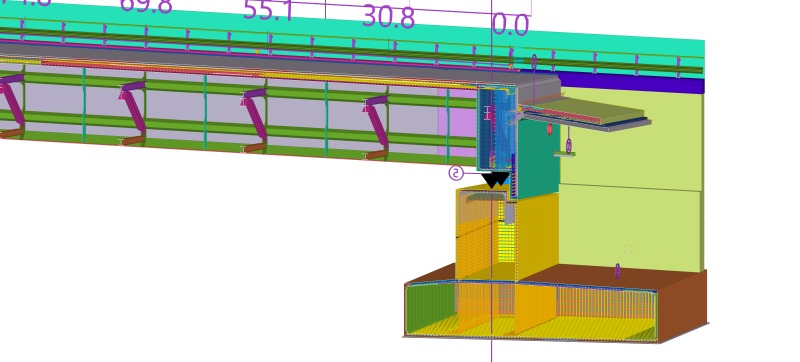

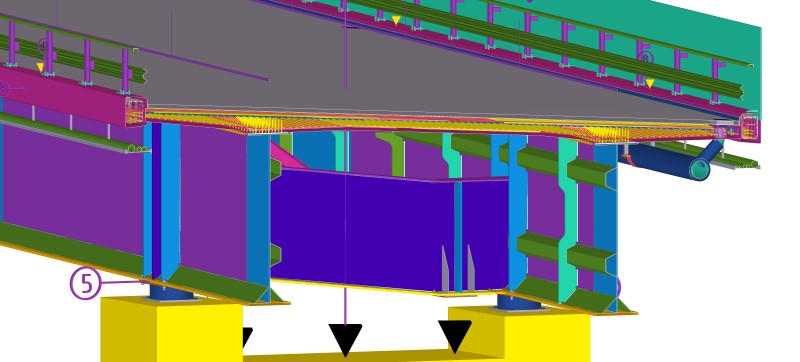

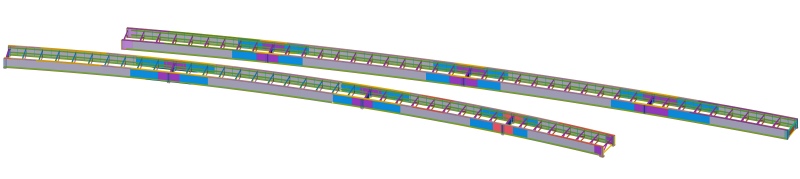

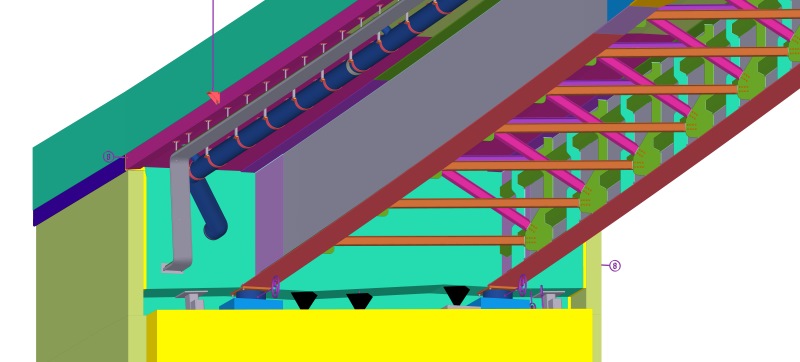

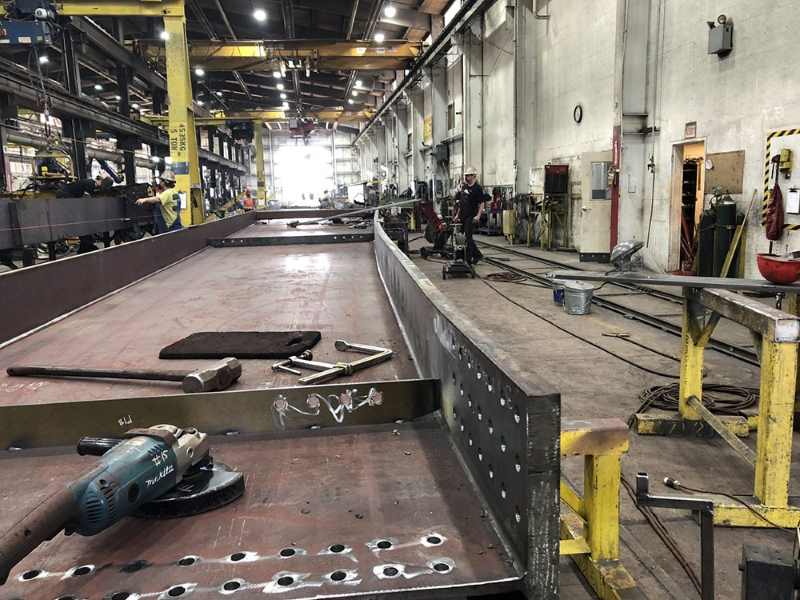

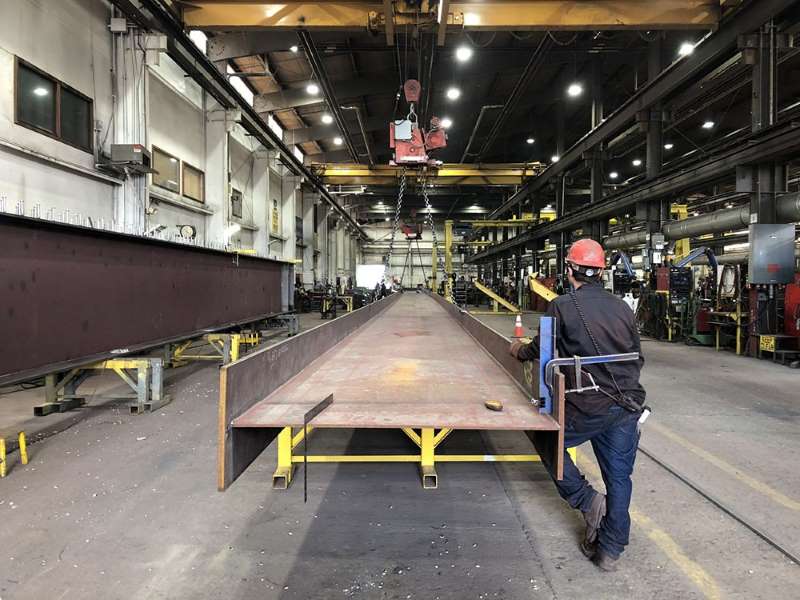

● Hommelvik bridge viaducts((southbound and northbound): The structures are 240-meter-long composite bridge girders composed of two welded longitudinal steel beams which support a 15-meter-wide deck, They are 4-span cooperative bridges with a total length of 228m and 251m.

The fabrication work including the carrying out of steel fabrication, welding, surface treatment and quality surveillance of the assembly of steel componts. These bridges are based on five axes: two abutments and three rectangular concrete columns. Regarding the foundations, footings are used to transmit the bridge loads to the terrain. All reinforced Concrete works were done by others at site.

● +15300 m3 of structural concrete (by others)

● +1760 Tn of structural steel (By ZHM Huawu Steel)

● +2250 Tn of reinforcement steel with +150.000 rebars (by others)

● +6000 Welds (Majorities were By ZHM Huawu Steel)

● +650 Bolt groups (Majorities were By ZHM Huawu Steel)

Project Descriptions:

An integrated model-based design has been implemented in our way of working with special focus into design optioneering and added value solutions for an efficient data handover for construction and operation purposes. This has been achieved through a close collaboration between the ZHM Huawu Steel Engineering team with the various stakeholder’s involved in the design, review, approval, and construction process. All against a data rich model from where teams can review and extract information.

Following are described the main methods implemented for each structural type:

Tunnel portals:

● The reinforcement of the foundations and the barrier have been done directly in Tekla.

In addition to graphical detail, information is also key in ensuring the right data is captured during the design process to be shared for construction and operation. A complete set of attributes was identified and implemented across al the model objects including project data, structural data, “processkode” and asset codes such as Brutus and Coclass. Also, an information box has been placed on each of the structures with key information for a more comprehensive data interrogation through the model.

The E6 Ranheim-Værnes has special emphasis in how to build a safe and sustainable infrastructure. For that purpose, all risk related to each structure are included and highlighted in the model to facilitate risk identification and communication to the teams.

Why ZHM Huawu Metal Highway Viaduct Bridge Steel Structures ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Highway Viaduct Bridge Steel Structures ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com