Steel Lattice Towers | ZHM Huawu Steel,China

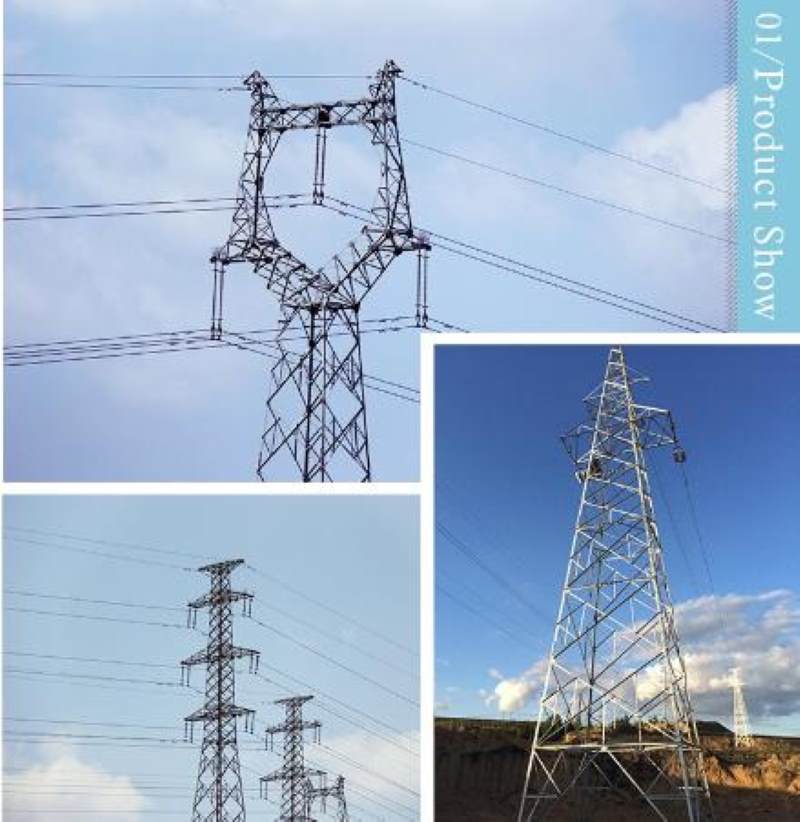

Since our establishment, steel lattice towers have been our primary featured product. Here at ZHM Huawu Steel, we have the advanced technology and expert production experience necessary for the design and production of high quality, durable steel lattice towers.

Our steel lattice towers can be used as a transmission line tower, communication tower, broadcast tower and watchtower. It has a truss structure, which is an ideal structure for large towers, and it is made from both Q235 steel and Q345 steel to ensure that it features an excellent performance in terms of strength, and plasticity to welding performance. The steel lattice tower is relatively light weight, which saves on steel materials and ensures it’s cost effective. The maximum height is 160m.

Every component of steel lattice tower is connected through electric welding or by connecting plates, bolts and screws, ensuring its durability. In order to extend the service life, each steel piece is galvanized for an excellent rust resistance. Moreover, after the installation, our team will test its quality to ensure a great operating performance.

Our professional design team will design and customize steel lattice towers used in different terrains, environments, and feature different functions. Our experienced after sales service team offers guidance and solutions for an on time installation and any after-sales problems.

Delivery will be 30-60 days depending on order quantity.

Detail Information

|

Design Software: |

PLS And MS Tower, SAP2000,etc. |

Standard: |

ASTM A123/ A123M-15 AS/ NZS 4680 |

|

Surface Coating: |

Hot Dip Galvanization Or Painting |

Voltage Grade: |

10-750KV |

|

Galvanization: |

Hot Dip Galvanization |

Painting: |

According To Clients' Request |

|

High Light: |

steel lattice tower, lattice transmission tower |

|

|

Overhead Line Lattice Steel Towers

Quick Detail:

66kV/230/330kV Overhead Line power tower single Circuit Tower steel lattice tower :

Lattice towers are the workhorse of the world’s electric grid.

ASTM A36 Equivalent to Chinese standard Q235B.

Description:

Since its establishment, ZHM Huawu Steel has been devoting itself to research,development and manufacturing of pole and tower. It has rich experience in manufacturing and design.

Applications:

66kV/230/330kV Overhead Line power tower single Circuit Tower steel lattice tower : The tower was erected on the tower cat shaped head, two wire lightning line, an isosceles triangle arrangement, it is also the

110 thousand kV and above voltage transmission lines of common tower can save line corridor, the economic and technical indicators than the glass shaped tower is worse.

Specifications:

The product features:

As the traditional transmission line equipment, Angle steel tower has the field widely used, the characteristics of the design code, the craft is mature, at different distances, different voltage level are showing the advantages and general applicability

The design of Power Transmission line tower depends on, type of conductor and Earth-wire, wind zone, deviation angle and material specification. These towers are galvanized to protect the steel from corrosion. The galvanizing coating thickness depends on the weather conditions at the location of tower.

Transmission Line Steel Tower & Substation Structure- Goods description and major parameters:

| No. | Description | Detailed Specification and Major design Parameters |

| 1 | Design Code |

1. Chinese National Standard: a. DL/T 5154-2002 Technical Regulation of Design For Tower and Pole Structures of Overhead Transmission Line b. DL/T 5219-2005 Technical Regulation for Designing Foundation of Overhead Transmission Line 2. American Standard: a. ASCE 10-97-2000 Design of Latticed Steel Transmission Structures b. ACI 318-02 Building Code Requirement for Structure Concrete |

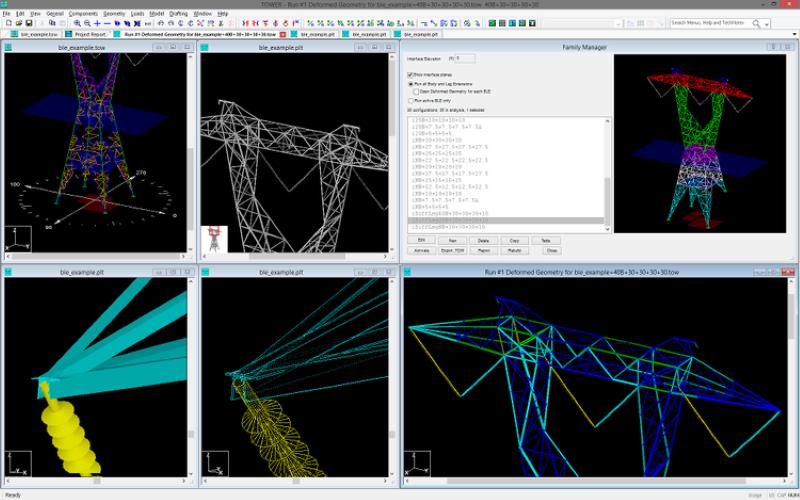

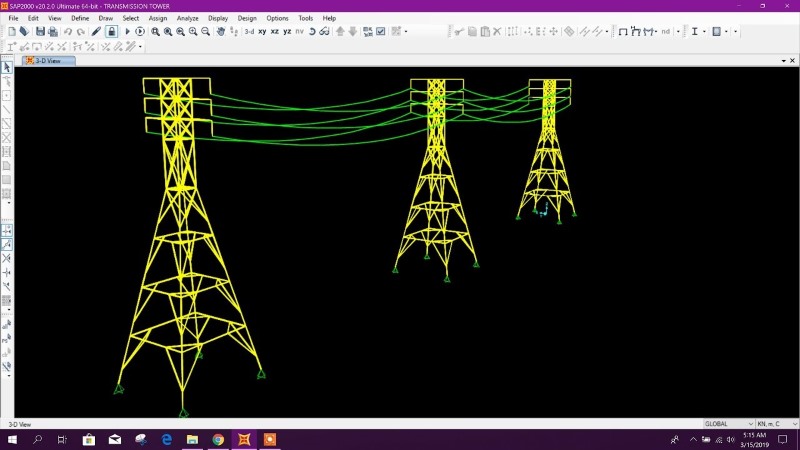

| 2 | Design Software | PLS and MS Tower, SAP2000, AutoCAD, STW, TWsolid, SLCAD,PLS-TOWER etc. |

| 3 | Design Loading | As per requirement and specification by Clients worldwide. |

| 4 | Load test/destructive test | We can arrange it by Government authority if it is necessary and the cost of such kind of test is separately from the tower pricing. |

| 5 | Voltage | 33KV, 66/69KV, 110KV, 220KV/230KV, 330KV, 380/400KV, 500KV, 750KV, 800KV, 1000KV Transmission Line |

| 6 | Hot-dip galvanization | ISO 1461-2009, ASTM A123 |

| 7 | Steel Grade |

1. High strength low alloy structural steel: Q420B which is equivalent with ASTM Gr60 2. High strength low alloy structural steels: Q355B which is equivalent with ASTM Gr50 or S355JR 3. Carbon Structural Steel: Q235B which is equivalent with ASTM A36 or S235JR |

| 8 | Bolts and Nuts | Mainly ISO 898 grade 6.8 and 8.8 bolts for Both Chinese, ISO and DIN standard |

| 9 | Tower Type | Angular Towers, Tubular Towers, Guyed Mast, Monopole Tower |

| 10 | Tower Type | Suspension Tower, Tension Tower, Dead Tower, Substation Structure |

| 11 | Warranty | Tower structures: 10 years |

| 12 | Return Period | 50 Years |

| 13 | Transportation | We are very close to the biggest port in the world which is our advantage for sea transportation. |

| 14 | Quality Control |

Follow ISO 9001 system and strictly QC inspection for raw material, prototype assembly test, galvanization test and pre -shipment inspection for the both quantity and quality We treat the quality first and 100% inspection ratio. |

Steel Grades

Angle Steel: Chinese steel Q345B, which same to ASTM A572 GR50

Other webs, bracing and not stress plate and angle steel: Chinese Q2230B, which same to ASTM A36

Plates: Chinese steel Q345B, which same to ASTM A572 GR50

Bolts: Chinese grade 6.8 and 8.8, which similar to ASTM A394

A) Dimension and tolerance for angle are according to GB/T1591-1994

B) Hot dip galvanization in accordance with GB/T 13912-2002, which similar to ASTM A 123

C) The welding will be performance in accordance with AWS D1.1 or CWB standard

Voltage: Power transmission equipment/electric transmission line Angle Iron tower grade:35KV/66KV/110KV/220KV/330KV/500KV/750KV/800KV/1000KV

Production Process

Here is fabrication process for our transmission tower; however, both parties must discuss all drawings and confirm all shop drawings, technical specification, and which standard to conform. Before mass production, we must received all signed approved shop drawings and technical documents from our client.

Our Fabrication shall be in strict accordance with detail Drawings prepared by the Contractor and approved by the Engineer. Fabrication shall begin after the approval of the shop assembly and tests.

| Shearing |

A: Shearing and cutting shall be performed carefully and all portions of the work which will be exposed to view after completion shall be finished neatly. Manually guided cutting torches shall not be used. B: All material over 13 (or 12) mm thick shall be cold sawn or machine flame cut. C: Cropping or shearing shall be allowed for material thickness of 13 mm or less. Flame cutting of high yield steel shall be preceded by a slight preheat operation by passing the cutting flame over the part to be cut. All flame-cut edges shall be ground clean. |

| Bending | Our company owaned the bending machince. Frether more, we can manufacture the towers with hot bending or cold bending according to client's requirements. |

| Welding |

No welding shall be done unless prior approval has been obtained from the Engineer. Welding shall not be allowed at tower attachment points for conductor, shield wire, insulators or associated assemblies or brackets |

| Sub-punching |

All holes in structural steel less than 10 mm thickness may be punched to full size unless otherwise noted on the approved Drawings. Holes shown on the Drawings as drilled holes and all holes in structural steel 10 mm or more in thickness and tension members of cross-arms shall be drilled or sub-punched and reamed. All holes shall be clean cut and without torn or ragged edges. All burrs resulting from reaming or drilling shall be removed. All holes shall be cylindrical and perpendicular to the member. Where necessary to avoid distortion of the holes, holes close to the points of bends shall be made after bending. |

| Punching | For punching to full size, the diameter of the punch shall be 1.0 mm larger than the nominal diameter of the bolt, and the diameter of the die shall not be more than 1.5mm larger than the diameter of the punch. For sub-punching, the diameter of the punch shall be 4 mm smaller than the nominal diameter of the bolt, and the diameter of the die shall be not more than 2 mm larger than the diameter of the punch. Sub-punching for reamed work shall be such that after reaming no punch surface shall appear in the periphery of the hole |

| Hole Size | Where holes are reamed or drilled, the diameter of the finished hole shall be not greater than the nominal diameter of the bolt plus 1.0 mm. |

| Galvanizing |

All material shall be hot-dip galvanized after fabrication in accordance with the latest revision of GB/T 13912-2002 or ASTM Specification A 123. Material that has been rejected because of bare spots or other coating defects shall either be stripped and re-galvanized, or the uncoated areas shall be recoated by an approved method. All plates and shapes which have been warped by the galvanizing process shall be straightened by being re-rolled or pressed. The material shall not be hammered or otherwise straightened in a manner that will injure the protective coating. Approval shall be secured from the Engineer if galvanizing is done outside of the Contractor's plant. All galvanized steel work shall be protected against white storage stain by using an approved solution treatment immediately following galvanizing. |

| Packing | Our product will be packed into several bundles whose weight is 2~3 MT or according to your requirement. |

|

Hot dip galvanizing |

Standard | Steel thickness/mm |

Mean coating thickness/μm |

Metallic Element |

Content |

|

Pole shafts,cross arms&bolted on accessories |

ASTM A123/ A123M-15 AS/ NZS 4680 |

>6 | 85 | Mn | 0.25%-0.40% |

| <3-6 | 70 | ||||

| 1.5-3 | 55 | Cu | <0.15% | ||

| <1.5 | 55 | ||||

| Bolts,nuts&washers | GB/T 5267.3-2008 | _____ | ≥ 54 | P | <0.025% |

| (ISO 10684-2004) | |||||

| Foundation bolts |

ASTM A153/ A153M-09 |

_____ | ≥ 54 | S | <0.03% |

Competitive Advantage:

1. Experienced staffs replying your inquiry in 24 working hours in fluent English.

2. Customized design is available. OEM&UBM are welcomed.

3. Perfect after sales service. Exclusive and unique solution can be provided to our customer by our well-traine

and professional engineers and staff.

4. Professional factory direct :Best price and timely delivery can be assured.

5. Very convenient transportation.

6. As an honest manufacturer and seller, we always use superior raw material, advanced machines, skilled technicians to ensure our products to be finished in high quality and stable feature. Welcome to contact us or visit our company anytime.

In the whole pole and tower manufacturing industry, experienced engineers and designers make the Company be available of designing accurately and timely and ensuring quality, safety and easy construction. On the basis of an excellent design team, the Company further configures software of PLS-Tower, AutoCAD, BOCAD and other CAD and updates the software in real time to ensure the software is the latest.

Supported by both domestic engineering company and ZHM tower design center, could provide technical consultant and design service within our scope of work. For ZHM tower design center, most of the engineers are local staffs.

The Design is based on ASTM protocols meantime with GB material standard, which will reduce the weight, and avoid the replacement on the profiles to save the working time.

Project management—Your ZHM Utility project manager oversees all the details necessary to ensure your project delivers as specified. What’s more, he/she communicates with you every step of the way.

Package

Set-wisely packing or member-wisely packing as per client's requirements.

Tower members: One steel tower is separated into several bundles.

Bolts: Packing material is robust nylon bag or steel drum.

International Fully Automatic Pollution-free Galvanizing Line

All the production line of galvanization is sealed off, it is operated by 7 workers with a yearly capacity of 160,000 tons.

In the new production line, we invest whole package of lifting equipment, all the loading works will be completed in our factory, in this case, it will be avoided two times loading during transportation, we are doing our best to protecting our products as always.

The new production line has improved on the part number tracking system, with this system we are doing better to avoid the missing parts problem

7. Customer Visit

Clients visited ZHM for factory inspection, we talked about the key issues faced right now, and found ways to solve it together. They set a high value on this cooperation.

Tag:

lattice transmission tower power transmission tower steel lattice tower

Why ZHM Huawu Metal Steel Lattice Towers ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Steel Lattice Towers ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com