1. Back Ground of The Retrofitted Building Steel Structure Project:

ZHM Huawu Steel were appointed to provide structural and civil engineering services for converting the existing 3-storey warehouse at city downtown Road to a 6-storey commercial unit.

The old building was a 1970’s textile warehouse resigned to demolition, until ZHM Huawu Steel, was invited to explore ideas for redeveloping it. ZHM Huawu Steel retained as much of the existing building as possible while adding multi- aspect windows, user- controlled natural ventilation, solar shading and three floors via a roof extension. Providing flexible workspace and comfortable working conditions.

In response to the client’s brief to provide new creative workspaces, the ambition is to create a high-quality, sustainable building, which stands as an exemplar towards the increasingly vital retrofit agenda by maintaining as much of the existing building, and its embodied carbon, as possible.

2. Characteristics Of the Buildings

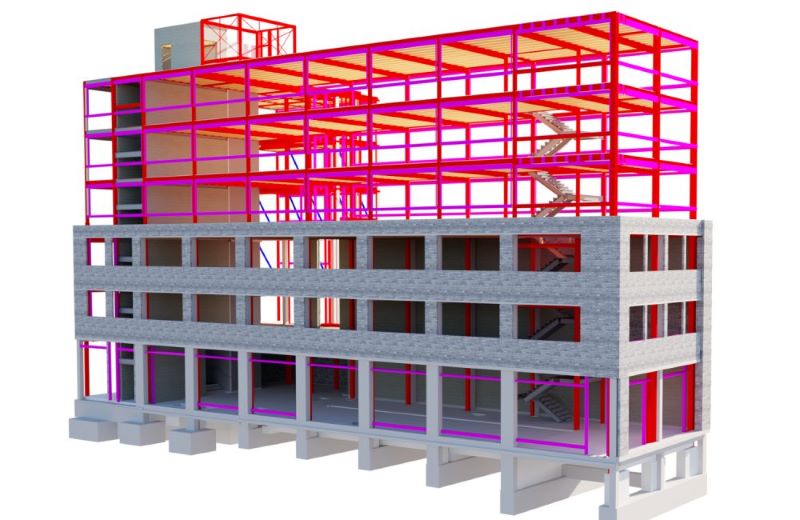

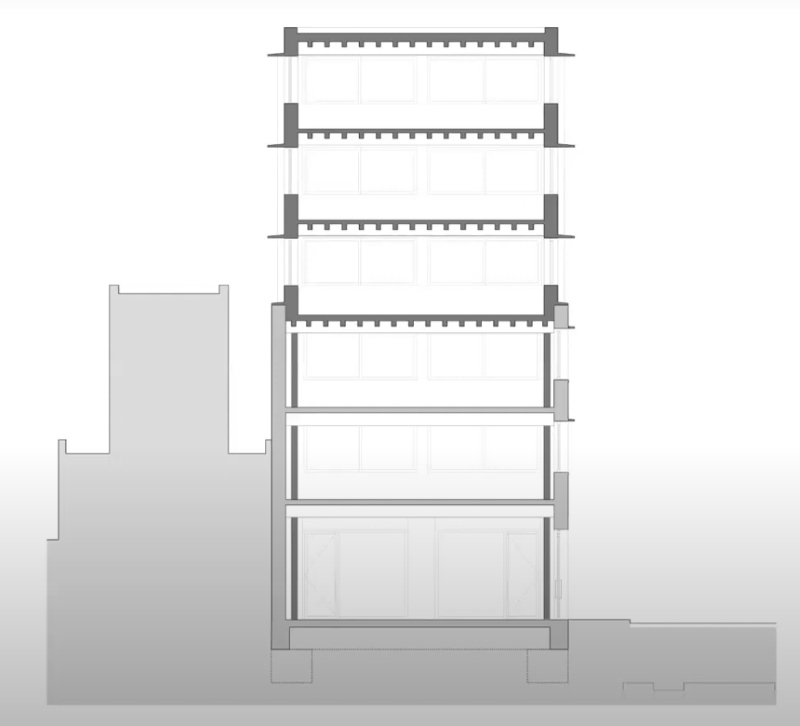

The characteristics of the existing warehouse building are not erased, but instead form the basis for the composition of the new lightweight extension, which improves its proportions, setting and overall functionality by doubling its height with a new three-storey, timber-framed structure.

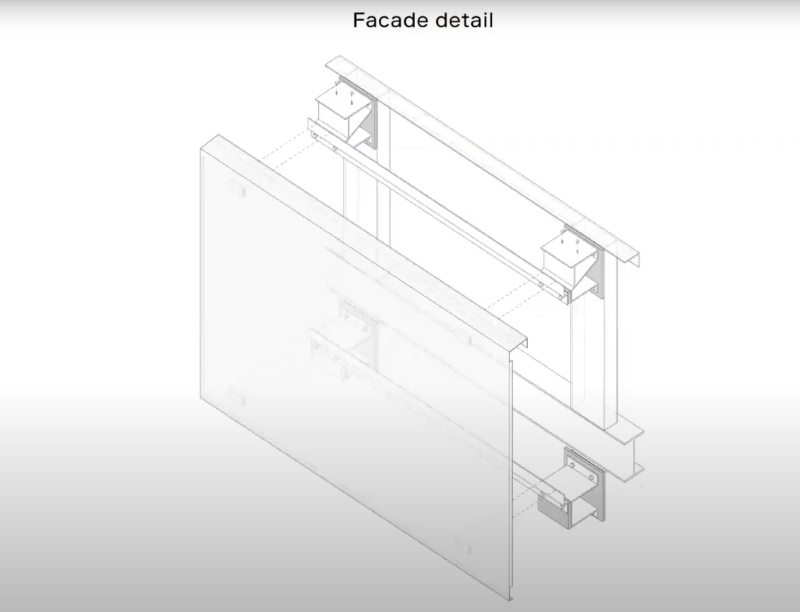

The new façade continues the structural pattern of the existing grey brick base, albeit with a light appearance of hot dipped galvanised steel fins, which allow daylight into the upper floors. The architectural composition of old and new is seen as a cohesive whole, united by a palette of silver-grey materials.

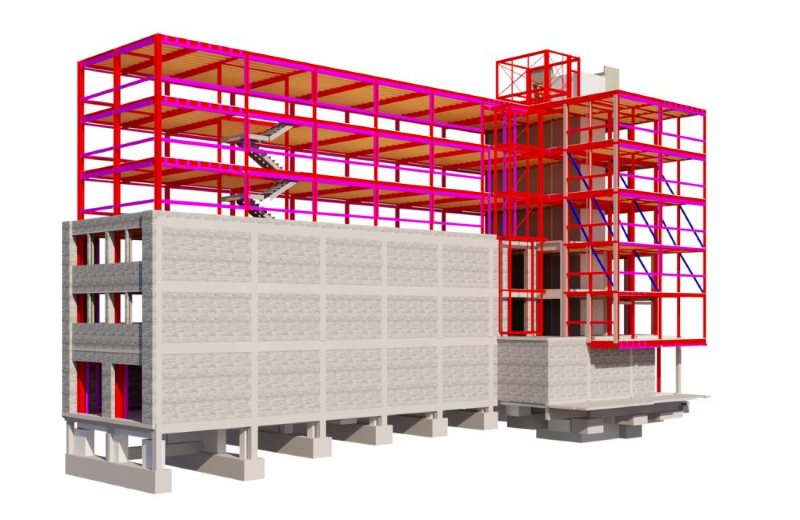

Three new commercial floors were added on top of a three storey 1970s concrete framed warehouse, using latent capacity for foundation, column strengthening and timber floorplate to achieve an efficient design.

The original structure was a 1970s concrete frame, with limited archive information available. Extensive structural investigations revealed elements of low strength concrete. The proposed structure therefore functions as an ‘endoskeleton’ for the building, with new columns installed at lower floors that not only support the new extension storeys, but also strengthen the existing structure. This provides greater confidence in the structure’s future robustness, while avoiding intrusive work to reinstate wall ties and strengthen existing columns, etc.

Existing metro subway under the site meant that avoiding any foundation strengthening was a priority. Detailed geotechnical assessments were carried out in order to determine the allowable load increase on the existing foundations, minimising differential settlement and any associated impact on the buried infrastructure. To keep the loads low, the extension was designed as a lightweight steel structure with timber floors. The fire engineered timber is to be left exposed – both to minimise embodied carbon and to provide an aesthetically pleasing ceiling.

A restricted access corridor at ground floor associated with metro subway infrastructure meant that to maximise the site footprint, the rear 6-storey steel and timber extension was cantilevered off the new stability core, avoiding the requirement for new foundations and columns within the restricted access zone.

The drainage design followed the hierarchy of surface water disposal and explored all available options to attenuate rainwater in a heavily constrained site. The design followed a sustainable approach to meet the requirement from the local flood authority to discharge at greenfield rates, by integrating a concrete attenuation tank seamlessly with the building’s ground floor slab. This strategy not only addressed the requirement of stormwater management, but also optimised the use of available space making it an efficient and sustainable solution. This solution allowed to design the tank at a very shallow depth to ensure a gravity discharge could be achieved by reusing the existing connection to the public sewer and avoid works in the main road.

Why ZHM Huawu Metal Crane Buildings | Steel Crane Buildings ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Crane Buildings | Steel Crane Buildings ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com