Shop House Building Kits for sale | Steel Shouses | ZHM Huawu Steel,China

Shop House Building Kits for sale | Steel Shouses

Building kits, design ideas & plans for modern Shouse homes

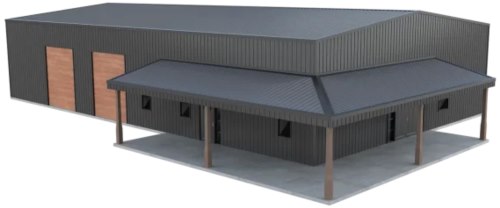

A steel prefab building is THE solution for your new shop house (Shouse). The integrated live-work structure is economical, requiring only one foundation and one structure. You can customize your home and its attached workshop space to your unique needs.

What is a Shouse?

A Shouse (shop + house) is a durable building that combines residential and commercial or workshop spaces under one roof.

Built with commercial-grade metal framing and sheeting, these buildings are energy-efficient and can be customized to fit your specific needs.

With open-plan living spaces, high ceilings, and ample storage, Shouses are popular with anyone who needs a living space and workspace in one location.

Start your project with ZHM Huawu Steel.

Made in China | Solid Steel |30 Yr Warranty | Custom Engineered

Top selling Shop House Building Kits products

Showcases of Custom shop house projects

Why choose a shop house?

|

|

|

|

China-made, I-Beam steel framing, custom-engineered in factories across the world. Shomes offer a huge range of structural options in a pre-engineered bolt-together kit. The home-portion of the shop house can be one configuration and style, with the attached workshop section having its own customizations and configuration. You can use a professional erection crew, or you might want to go DIY. Many buyers choose to self-build - making these structures an extremely economical live-work option. This durable, pest-proof, rot-proof structure will add to your property’s equity. Structural warranties are 30+ years. And this could be a big plus: you can quickly and easily adapt to future growth. Simply remove the end wall sheeting, pour a new concrete slab and add additional workspace. Be sure to specify 'expandable end walls' when ordering if this is a possibility. A fast to build, economical & flexible housing choice |

|

Shop House Buildings features

Start your project by customizing a standard-size metal building kit package to create a space that meets your specifications for access and functionality.

You get exactly the shop house you need by specifying height, roof style and pitch, exterior finishes, colors, door and window sizes, and types.

By configuring these options, you can create a space that meets your storage or workshop requirement and complements your existing buildings.

Shouse packages include:

Steel I-Beam framing

Steel roof & wall panels (26ga)

Complete trim package

Two framed door openings

Foundation anchor bolt plans

Engineer stamped plans

Kit delivery

Installation instructions

All bolts, flashing & sealants

Metal building features

Bolt-up construction

Trussless roof design

Clearspan widths to 300'

Certified to 160 MPH wind

Certified to 110 PSF snow

30+ year warranty

Fast, free delivery

Fast build & times

Custom options:

Doors - Choose overhead garage doors, rollup, sliding or bifold door options.

Roof profile & pitch - Adjust the gable roof pitch or select a single-slope, gambrel, or monitor profile

Insulation - Opt for vinyl-faced fiberglass, spray foam, or insulated metal panels (IMPs).

Structural upgrades - Add porches, overhangs, a carport lean-to, or a mezzanine for loft storage.

Colors - Mix & match siding, roof, trim, and wainscot color options for a custom look.

Items not included:

Permits

Foundation

Installation

Insulation

Interior build out

Nine ways to save on metal buildings

Based on conversations with our previous customers, contractors, and suppliers, here are some quick tips to help you save on your new steel building.

1. Shop around. With so many suppliers offering different deals, getting quotes from multiple suppliers is essential. Also, most suppliers offer free shipping, so you don’t need to buy locally if you don’t want to.

2. DIY. If manageable, erecting the structure yourself can lead to substantial savings. Most people can reduce the total cost by approximately 20% to 30% by taking on this task.

3. Simplify the design. Opt for a straightforward design. Complex designs necessitate extra steel and more engineering effort, increasing the final cost of your new build.

4. Minimize expensive design changes. As with any large project, careful planning is critical; overlooking current requirements can lead to unexpected future expenses. Once production starts, making changes can be costly.

5. Choose a basic roof style and low pitch. A single-slope roof with a 1:12 pitch is the most economical choice. Like the design aspect mentioned earlier, intricate roof styles like monitor and gambrel require additional materials and engineering time. A gable roof with a 2:12 pitch strikes the perfect balance for most buyers.

6. Minimize door and window openings. Framed openings should be kept to the bare minimum as their costs accumulate rapidly. Also, opt for standard-sized options wherever possible, preferably those that are easily obtainable in your local area.

7. Reduce the height. Try to be realistic about the height of your steel garage; the higher you go, the more materials are required, which will, in turn, increase the price. The additional space will also impact your heating, ventilation, and air-conditioning (HVAC) expenses.

8. Plan ahead for expansion. Red iron buildings can be expanded later if you specify ‘expandable end walls’ on your initial order. If you fail to do this, the expenditure of adding additional bays later will be significantly more expensive due to the additional engineering required.

9. Schedule off-season installation. Schedule construction in early spring or late autumn to save on contractor fees, especially in colder climates where these times are more cost-effective than summer.

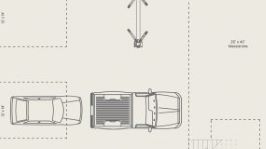

30' x 40' Shop house /garage

TIP: Choose as large a shop house as your budget and space will allow. The #1 complaint we hear is, ‘I wish I had opted for a slightly larger size.’

Pitfalls to avoid when buying a garage

Pre-engineered metal buildings are known for their affordability, durability, and fast install times. However, attention to specific details is essential for a successful project and a space that fulfills your requirements.

Not thoroughly planning the project. Avoid rushing the planning phase. Carefully consider all design elements to prevent costly modifications, budget overruns, and delays.

Ignoring local codes. Engage early with local authorities to prevent zoning or code violations, which could lead to legal issues.

Hiring the wrong contractors. Ensure the crew you hire has substantial experience installing pre-engineered buildings. Proper vetting is crucial.

Not comparing apples to apples. When comparing prices, ensure you're evaluating similar quality kits. Prefab metal buildings come in different grades. Cheaper options often found in online retail or big-box stores use tubular framing, which lacks commercial-grade steel I-beam frames' durability and load-bearing capacity. Remember, opting for a less expensive option means compromising on longevity, strength, and possibly safety.

Overlooking the importance of the foundation. A weak foundation is the leading cause of failure in pre-engineered buildings. It's crucial to hire a certified structural engineer for the slab design and choose a reputable concrete installation company.

Overlooking future growth. Anticipate potential growth. Including "expandable end walls" in your initial order is more economical than making modifications later.

Insulation and ventilation oversight. Proper insulation and ventilation are crucial for maintaining energy efficiency. Neglecting these can cause heat and moisture build-up, potentially damaging the framing and siding.

Buying purely on price. Steel shop house kits vary in price and quality. Be wary of suppliers who pressure for quick sales. Avoid making hasty decisions based on cost alone. Instead, obtain detailed written quotes from at least three suppliers and compare them thoroughly.

Questions to ask yourself before buying

After helping customers plan, configure, and purchase metal shop houses for over twenty years, here are some of the most important points to consider.

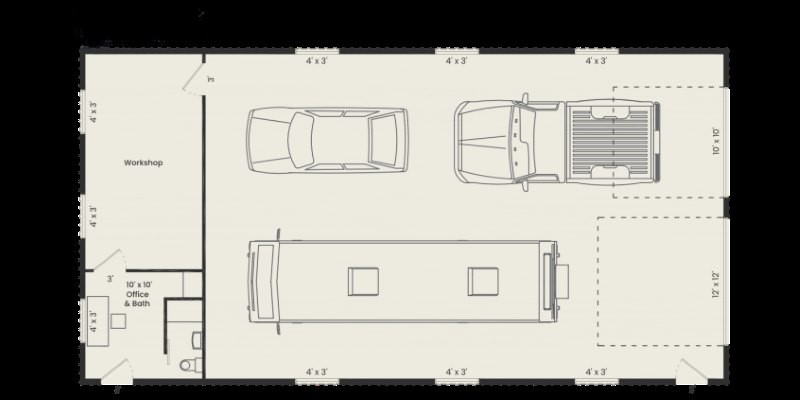

How many vehicles do I need to store? Allow 240 square feet for cars and 300 square feet for medium-sized trucks. This provides two feet of clearance on either side of the vehicle and three feet down the length. We recommend creating a floor plan to visualize your intended layout.

Do I need additional workshop or storage space for garden equipment, tools, ATVs, boats, etc.?

What is the maximum height of the vehicle I need to park? Add 2 feet above the door opening to the eave height for steel garages. For example, an 8-foot door requires a 10-foot eave height.

Will you require a half bathroom? (allow approx. 25 sq ft)

Will you need office space? (allow approx. 80-120 sq ft)

Layout for PEMB with office and half bathroom

30' x 60' shop houses with office & half bathroom

Do you need a second-story loft apartment or storage area? If so, choose a 16’ to 20’ height and install a mezzanine level.

Do you need heat? The most economical option is installing radiant underfloor heating, propane, or a natural gas convection heater. For 2-car garages, you will need approx. 35,000 BTUs, and for 3-car, you will need a 45,000 BTU system. For a low-cost option, consider a pellet stove.

Will you be washing cars inside? Then, plan to have floor drains installed in each bay for drainage.

Do you have (or will have) an electric vehicle? Consider running a 230-volt 40 Amp service to charge an EV.

Metal shouse building installation

Here is a brief overview of the build project; for additional details, see our article on how to plan, design, and build a shop house.

|

Site prep and concrete foundations

All steel shop houses will typically require a concrete slab. Although it is possible to have a dirt floor (if required), only piers are required in this case. For light loads, such as one to two light cars or trucks, the concrete should be at least four inches(100mm) thick, and for medium loads, such as one to two medium-sized trucks, a thickness of six inches(150mm) is recommended. |

Concrete Slab Foundation For Metal Building |

|

|

|

|

Construction options

Do-it-yourself (DIY). We only advise going this route on smaller buildings and if you have previous experience. Self-manage. You will hire and manage the various sub-trades to erect the building. Hire a General Contractor (GC). A GC will manage the entire project on your behalf, from pulling permits and installation to the final inspection |

Steel Garage Carport Installation |

|

|

|

|

Interior finishing

If you plan on having a separate bathroom, office, or shop space, these can be framed out using either 2x4 wood studs or steel studs and finished with drywall. Alternatively, you could install a mezzanine to provide a loft area. If this is a requirement, plan for an eave height of 14 to 16 feet. |

Metal Garage Building Mezzanine |

|

|

|

Garage kits FAQ

What is a typical metal shop house height?

With a metal shop house building, the height is measured at the eave. As a rule of thumb, you will need 2 feet above your highest opening. So for cars and trucks, you will need an 8-foot overhead door plus 2 feet to give you an eave height of 10 feet. For oversized vehicles, you will most likely need 12-14 feet.

What roof pitches are available for metal buildings?

Our steel building kits come with either a 1:12 or 2:12 pitch. Steeper pitches up to 6:12 are available as a special order.

Are other exterior finishes available?

Yes, our buildings can be customized with alternate exterior finishes to the standard PBR panels. Options include stucco, brick/stone veneer, and insulated metal panels (IMP). Please note that it is essential you discuss this option with your salesperson or project manager in advance to ensure that your steel building is appropriately engineered for these modifications. Retrofitting or remodelling a steel building isn't straightforward.

What are the lead times on metal buildings?

The timeframe for delivery is influenced by its size, complexity, and type, among other variables. Typical lead times can range from 30 to 90 days.

Related Articles

|

|

|

Garage plans, floor plans & layout ideas

garage floor plans

Unlock your dream garage layout with our collection of free detached garage plans and floor plans, expertly designed to meet the needs of homeowners, hobbyists, and commercial garage

|

Why ZHM Huawu Metal Shop House Building Kits for sale | Steel Shouses ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Shop House Building Kits for sale | Steel Shouses ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com