ACC Air Cooled Condenser Structual Steel Works | Medupi Power Plant,South Africa

ACC Air Cooled Condenser Structual Steel Works | Medupi Power Plant,South Africa

Medupi Power Plant– ACC Air Cooled Condenser Structual Steel Works

Location : Ellisras, South Africa

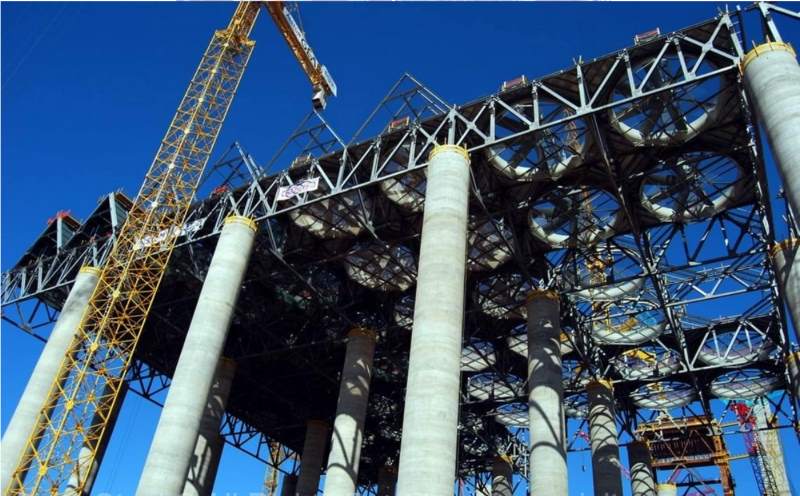

Year : 2010-2012

Tonnage : 16 000 tons

Medupi is a greenfield coal-fired power plant project situated in Lephalale, comprising six units with a gross nominal capacity of 800 MW each.

Drought currently plagues much of South Africa. It is one of a couple of dozen countries in the world facing extreme water stress.

That is one of the reasons why the country’s state-owned electricity provider Eskom elected not to build a water-cooled coal plant to solve its ongoing electricity shortage. Instead, it has built the world’s largest air-cooled coal plant.

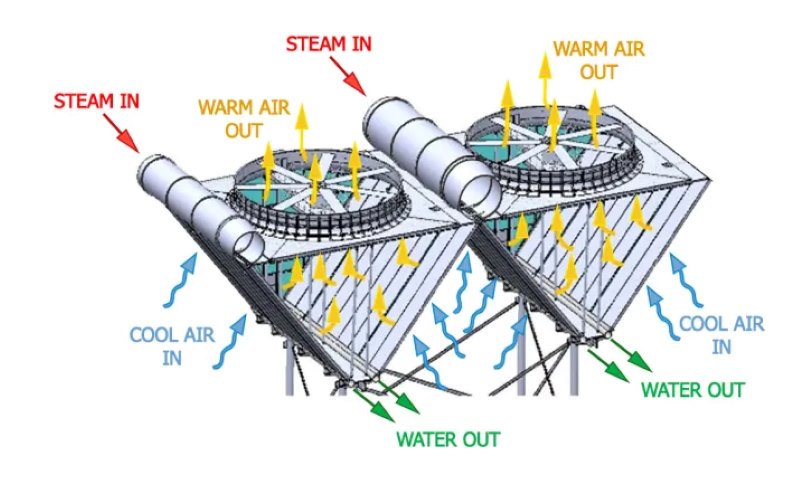

Known as the Medupi Power Plant, it still has to use river or reservoir water to produce steam for its six massive Alstom turbines. But actual water usage is minimized by reusing as much of the water as possible. The lack of abundant water means Eskom must carefully utilize every drop of water it draws from local supplies – any waste must be minimized.

To ensure it achieves that goal, Eskom has installed an Ovivo Condensate Polishing Plant (CPP) at all six units. This technology eliminates the requirement for boiler blowdown by removing contaminants from condensate water so that clean water can be safely fed back into the condensate circuit and to the boiler for the production of steam. Thus steam is maintained at the highest quality which, in turn, maximizes power output and longevity of the complete steam-condensate circuit including turbine and condenser.

The Medupi plant is located at Lephalale in Limpopo Province, in the northern part of South Africa. this baseload facility is providing about 12 per cent of the nation’s power generation capacity.

The 4790 MW plant is the biggest dry-cooled power station in the world. It is composed of six Alstom STF100 steam turbines, each capable of producing 794 MW. Alstom – which is now part of GE – is also supplying its ALSPA Series 6 control system, while GEA – recently renamed Kelvion – is providing the air cooled condensers (ACCs), and Hitachi is suppling its supercritical boilers.

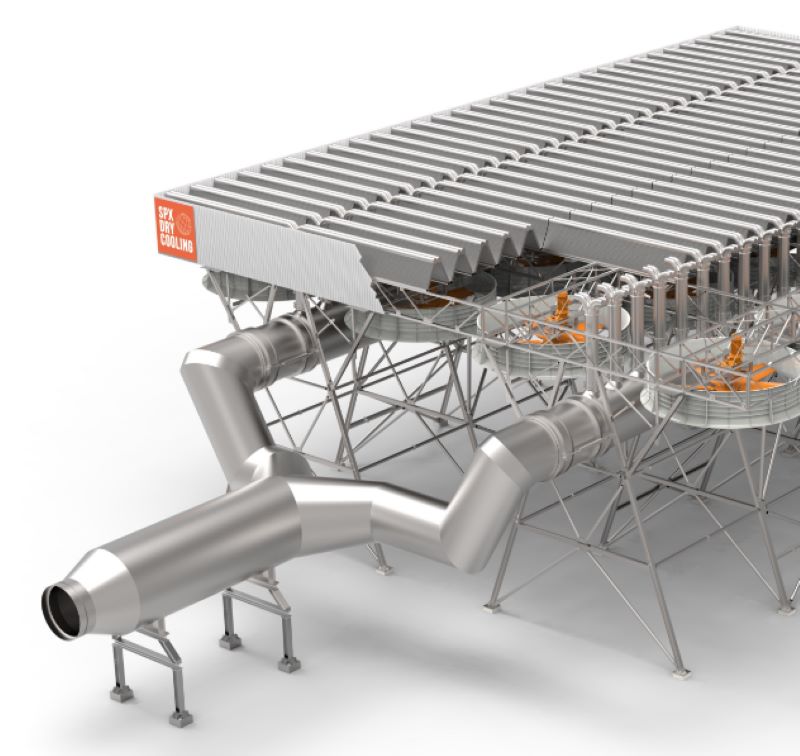

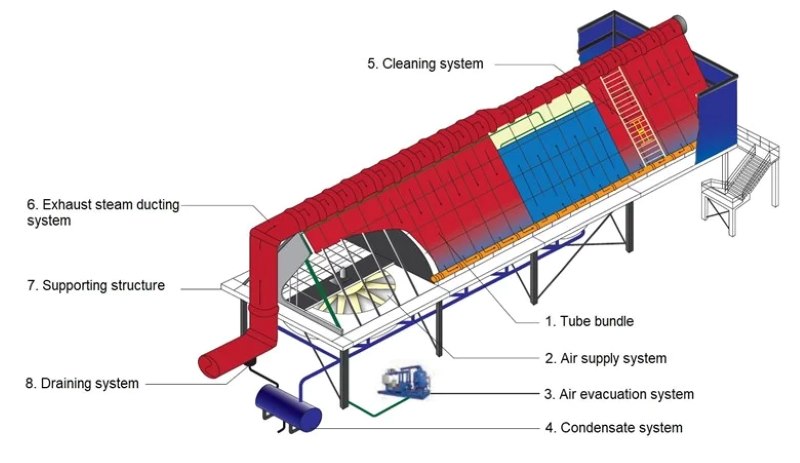

After using all the useful energy from the steam, it is sent horizontally to the air cooled condensers. A massive steel (ZHM Huawu Steel as the main subcontractor) and concrete structure supports the ACC modules which use GEA’s A-tube arrangement in order to maximize the volume of galvanized tubing subjected to cooling.

Why ZHM Huawu Metal ACC Air Cooled Condenser Structual Steel Works for Power plants ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal ACC Air Cooled Condenser Structual Steel Works for Power plants ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com