Why Trust ZHM Huawu Steel in your Steel Fabrication Projects?

No Pics.

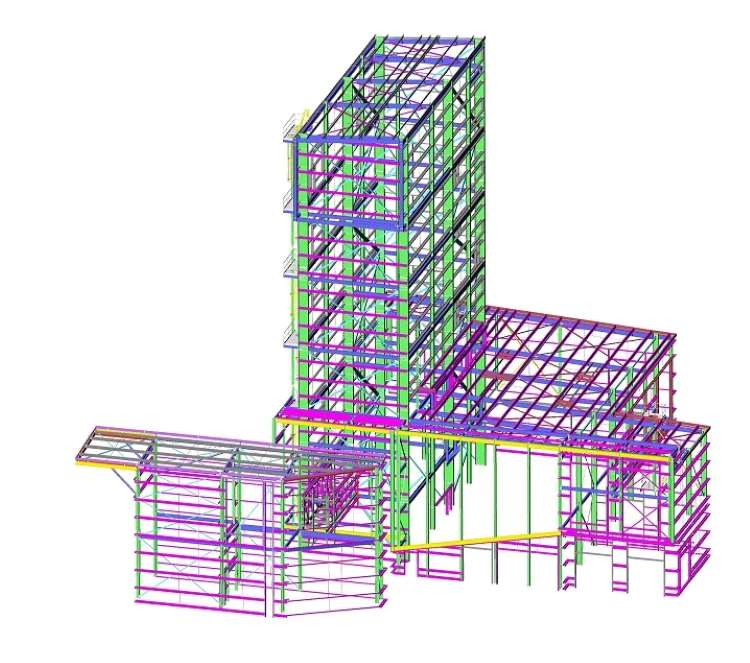

steel structures fabrication ZHM Huawu Steel Group

Steel or metal fabrication is a broad specialization. Technically, it is not a trade which regular welding companies or contractors can fulfill. It involves not just one or two but multiple operations that requires precision and expertise. It applies processes with high complexity to create value-added products essential to mining, energy, automotive, construction, medical, transportation, food, and all other business industries that exists.

Shortlisting and finally choosing the best candidate for a steel fabrication job is crucial as far as successful project completion is concerned. This is because successful completion does not only mean finishing a project on time, it follows accomplishing a project safely within schedule, within budget, and compliant to specified quality and standards.

Luckily, ZHM Huawu Steel got you covered and here’s why you should not just consider but rely on us.

FABRICATION CAPABILITIES

With a global capability of producing over 300,000 metric tons per year of steel products and structures at various locations and sites around the world, ZHM Huawu Steel provides one-stop solutions for projects of all scales and requirements. We employ not just state-of-the-art equipment and machineries but the most skilled and qualified labor assets that gets them into work. Below is a showcase of some of the capabilities of ZHM Huawu Steel's prequalified mills:

- Machining, Cutting & Drilling

- Welding

- Press Brake Forming

- Pipe Forming

- Blasting, Coating & Galvanizing

- Testing (Material, Weld, Coating, Dimensional)

In terms of structure types:

- Bridge Structures

- Pre-Engineered/ Prefabricated Steel Buildings

- Offshore Steel Structures

- Building & Construction Structures

- Mining and Excavation Equipment and Structures

- Prefab Components – Rail & Transport

- Material Handling Equipment

- Pressure Vessels

- Marine Structures

- Foundation Solutions

One of the criteria that qualifies a metal fabricator is its capability to design and formulate engineering solutions for different project specifics. A metal fabricator should be able to work with drawings, translate drawings and specifications to shop drawings, and design a project from scratch if necessary including undertaking field investigation works.

sheet pile manufacturer

1. Engineering Calculations

2. 2D and 3D CAD drawings

3. Design Software such as Finite Element Analysis

4. 3D visualization and animation

5. Material Engineering including Quality Tests

When combined, ZHM Huawu Steel fabrication facilities and logistics assets sums up to the following statistical figures:

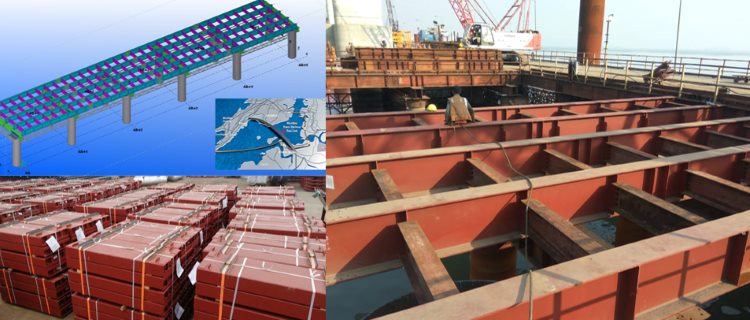

bridge manufacturer

5,381,955 ft2 (500,000 m2) covered fabrication working shop areas

1,076,391 ft2 (100,000 m2) covered blasting and painting working shop

21,527,821 ft2 (2,000,000 m2) open yard area in total more than 15 factories

800T gantry crane

2500 mT lifting capacity of floating crane

1800 mT per work piece can be handled and load vessel directly

328.084 ft (>100 m) long work piece can be handled and load vessel directly

26,247 ft (8000 m) waterfront shoreline with more than 20 berths for international vessels

With ZHM Huawu Steel’s well-established facilities in China, and its vast global sales and logistics network, the Company has been providing structural steel fabrications around the world for more than 20 years. Our track record in different continents and regions demonstrates a hard-earned success and recognition as characterized by a wide variety of project types and magnitudes – from small components to large structures. Some of our accomplishments are as follows:

dolphin piles fabrication

4 Steel Bridges (Papua New Guinea)

Coated Steel Girders for 12 Bridges (New West Britain)

SP Brewery Prefab Steel Building (Papua New Guinea)

Hinkley Point C – Temporary Jetty Steel Piles (United Kingdom)

Tug Harbor Pontoons (Australia)

Modular Transport Beams (United Kingdom)

Al Ittihad Road Footbridge (United Arab Emirates)

RAAF aircraft Hangar (Australia)

TWR Control Tower (Australia)

2 sets Access Chamber for Rondout Tunnel (New Yok, USA)

Mare Harbor Upgrades (Falklands)

Greensport Terminal (USA)

Islington Warehouse (Australia)

International Container Terminal (Philippines)

Bridge Spuds & Ornamental Steel Structures (Philippines)

Others:

fender installation platform fabrication

1.Hundreds of Marine Projects in Asia, Africa, North & South America, Europe, Australia, and even in the Antarctic Region. It includes Harbors, Jetties, Shipyards, Docks/Berths, Quay Walls, Seawater Intakes, Oil & Gas Platforms, Underwater Pipelines, Offshore Structures, Water Channels, Flood Control Projects, and many more.

3.Hundreds of global projects utilizing fabricated materials such as sheet piles, pipe piles, combi-walls, trench sheets, trench shields or trench boxes, marine bollards, marine fenders, tie-rods & connectors, struts, and so many more.

STANDARDIZATION/CONSISTENCY/QUALITY

ZHM Huawu Steel and its prequalified factories offer a diversified set of international certifications enabling it to undertake complex projects around the world in adherence to country and/or region specific standards. The certifications cover special fabrication, welding, testing, quality management systems and corrosion protection systems.

Company Certifications:

American Institute of Steel Construction (AISC)

Europian Union (CE)

EN 1090

ISO 9001, 14001, OHSAS 18001

American Welding Society (AWS)

China National Accreditation Service for Conformity Assessment (CNAS)

American Petroleum Institute (API)

ASTM International

ISO 3834

Canadian Welding Bureau (CWB)

Australian Certification for Reinforcing Steel (ACRS)

American Society of Mechanical Engineers (ASME)

International Zinc Association (ZINC)

Personnel Certifications:

American Welding Society (AWS)

American Society for Quality (ASQ)

American Society for Non-Destructive Testing (ASNT)

Chinese Mechanical Engineering Society (CMES)

International Institute of Welding (IIW)

Institution of Mechanical Engineers

LEAN Six Sigma

Project Management Professional

Society for Protective Coatings (SSPC)

NACE International

Society of Manufacturing Engineers

Company Memberships:

ASTM International

North American Excavation and Shoring Association (NAXSA)

National Utility Contractors Association (NUCA)

World Association for Waterborne Transport Infrastructure (PIANC)

Society for Protective Coatings (SSPC)

Deep Foundations Institute (DFI)

Pile Driving Contractors Association (PDCA)

CUSTOMER SERVICE

ZHM Huawu Steel's global network is well positioned to serve its customers with a group of strategically located offices in more than 20 countries in the following regions:

Asia & Middle East

Australia & Oceania

Africa

Canada & USA

South America

North America

Europe

We offer clients a dedicated project engineer for every work order, who is the focal point for communication and technical queries. This make project management more seamless and hassle-free to the client. We understand the need to interact closely with contractors, design consultants, owners and other project stakeholders.

PRICING

Prices differs from fabricator to fabricator, obtaining quotations from many providers and comparing the provisions in details is always an advantage in understanding the real extent of the project. The best metal fabricator for a specific job won’t necessarily have the lowest price or the biggest name in the business, there are parameters to look at instead when comes to identifying a company that can provide competitive proposals or prices:

steel bridges

- Proposal adapts to available budget and comes up with a sound, practical solution without sacrificing any of the project essentials.

- The fabricator has wide influence and material purchasing power

- Knows standard and realistic prices within the industry

- Can devise and explain the most cost-effective approach for all kinds of projects

- Has complete control of shipping and logistic operations including costs

ZHM Huawu Steel’s reputation is built on excellence and commitment in providing high-quality, efficient, and cost-effective solutions. We are capable of providing competitive prices by adhering to engineering innovations and advance technologies that enhances safety and product quality, reduces unnecessary operational costs, and creates added value to our products and services.

TO WRAP IT UP

This is simply because a well-experienced company is always a step ahead among others in identifying, avoiding, or dealing with implementation surprises and turnarounds which can be really painful and costly.

At ZHM Huawu Steel, we don’t say we are the best. But we say WE’VE BEEN HERE FOR MORE THAN 20 YEARS AND WE KNOW HOW IT IS DONE.

ZHM Huawu Steel steel structures

Please don’t hesitate to reach us at our office nearest to you. At ZHM Huawu Steel, we say “YES” and “NO” with CONFIDENCE.

Why ZHM Huawu Steel pre-engineered fabrication projects ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM’s Metal Steel Structure pre-engineered fabrication projects ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com