Hexagon Air Cooled Condensor Tower Structural Works | ZHM,China Manufacturer Factory Supplier

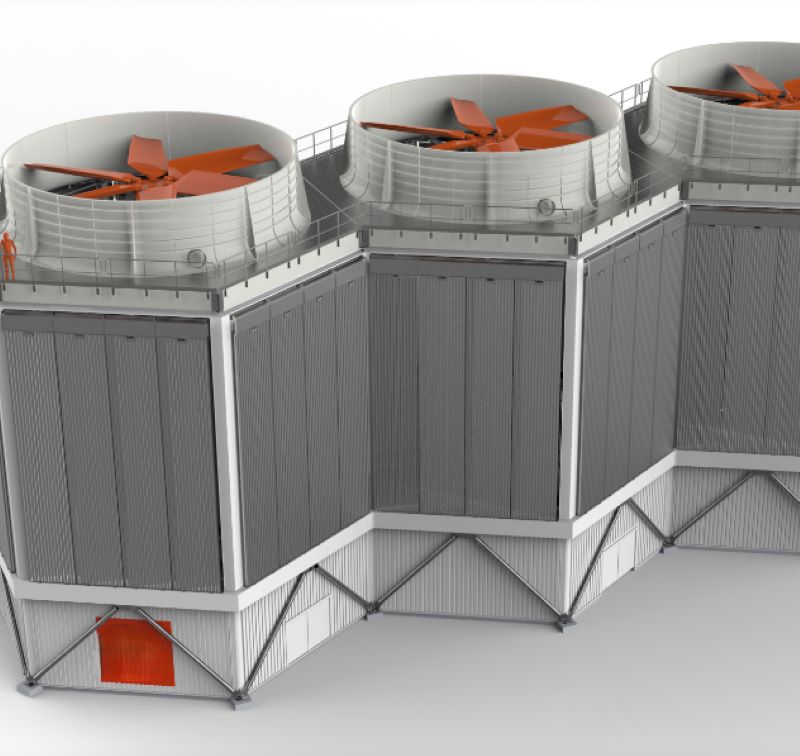

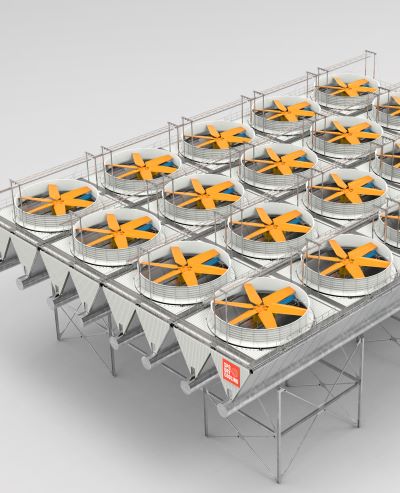

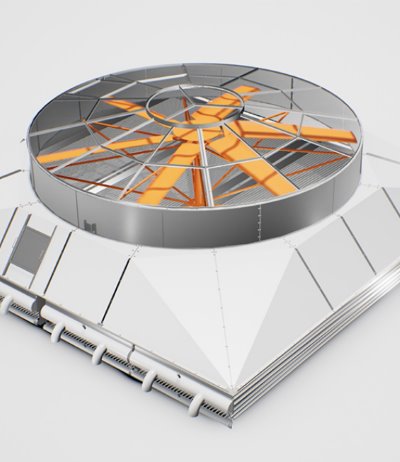

Hexagon Air Cool induced draft configuration saves up to 15% fan power consumption.

Hexagon Air Cool

Products About Hexagon Air Cool

Typical Hexagon Air Cool applications include

- waste-to-energy plants

- biomass power plants

- geothermal power plants

- small sized electrical power plants

- industrial/process plants, where Hexagon Air Cool is a more cost effective solution than a traditional A-Frame ACC.

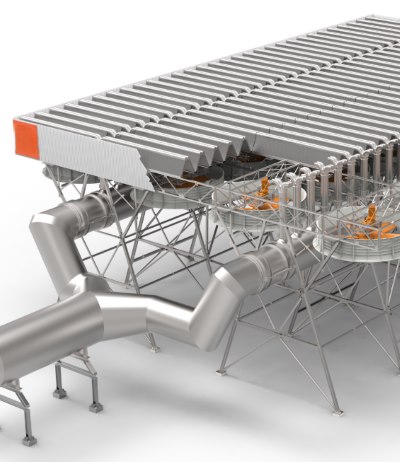

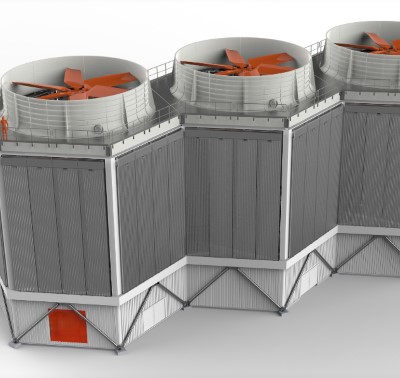

Features of Hexagon Air Cool

Hexagon Air Cool is a standardized, modulair air-cooled condenser system that is low in cost, easy to erect and robust in performance. It is the most suited solution for small power and industrial applications where a standard A-Frame model is not the most cost-effective solution.

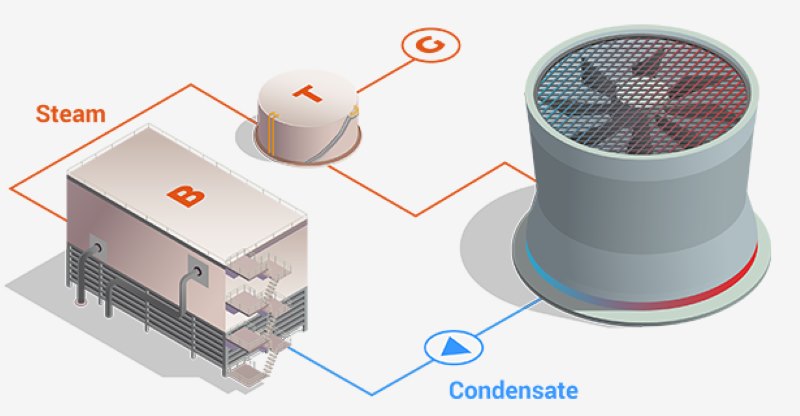

Watch the 3D video of Hexacool Air Cooled Condenser steam cylce

3D visualization of the product

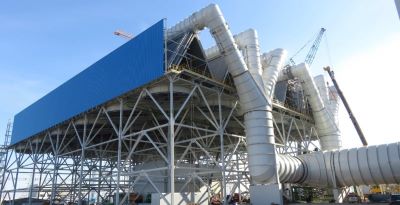

Projects installed in pictures

Benefits

|

01 Quality Hexagon Air Cool is a highly qualitative product and a cost-effective solution for your application. The design is compact and simplified thanks to the higher degree of prefabrication in the workshop. Hexagon Air Cool offers a reduced load on foundation. |

02 Cost-effective Hexagon Air Cool has a low profile design, the total height is lower than an A-Frame design. This results in an easier integration in urban environments and easier construction in the field. |

|

|

|

|

03 High performance Hexagon Air Cool offers an outstanding performance during windy conditions. The induced draft concept reduces the risk of hot air re-circulation. This leads to a higher efficiency in all operating conditions. |

04 Sustainability Hexagon Air Cool is a trendsetter in the industry thanks to its environmentally friendly design. The units are designed for easier cleaning and maintenance. |

|

|

|

Case studies of Hexagon Air Cool, Get to know clients that installed Hexagon Air Cool Air-Cooled Condensers

Highlighted Case study: Hassi R’Mell

Another great installation by ZHM Huawu Steel Dry Cooling! Hassi R'Mell is a 150 MW power plant, located in Algeria. The power plant combines 25 MW concentrating solar power array, covering an area of over 180.000 m2, with a 130 MW combined cycle gas turbine plant.

View case

Minimize the risk of downtime and expand asset`s lifespan. Tailored to your needs, ZHM Huawu Steel Dry Cooling offers a variety of maintenance services. Keeping your dry cooling system performing at optimal levels. Our programs allow you to conduct best practices, maintenance and repairs in an efficient way.

Read more about maintenance services of air cooled condenser structure systems

Start your journey with ZHM Huawu Steel Dry Cooling

| Step 1 | Contract Signature |

| Step 2 | Kick-off Meeting:With ZHM Project Manager,Engineering team, Quality Control Officer, Logistics officer as well as with equivalent representatives from the client-side. |

| Step 3 | Engineering Phase:In the first phase, ZHM Huawu Steel will hand the client a basic design of the requested product. In the second phase, we will start with a more detailed design. |

| Step 4 | Procurement Phase:With ZHM Huawu Project Manager,Engineering team, Quality Control Officer, Logistics officeras well as with equivalent representatives from the client side. Our Sales Manager will also be there, and often the client's procurement manager too. |

|

Step 5 |

Fabrication Phase: |

| Step 6 |

Delivery to Client: We can make the equipment and materials available for client pick-up.Or we can deliver goods to the project site. |

| Step 7 | Erection on Site: Erection Technician Supervision Service can be provided as an option. |

| Step 8 | Commissioning: Commissioning Supervision is provided by one of our experienced technicians. |

All projects require a different and unique approach. Your first point of contact with ZHM Huawu Steel Dry Cooling will be our dedicated and experienced sales team. You will have a committed team (project manager, engineering team, quality control officer, logistics officer) at your disposal through the whole process. Our team members offer a high quality of customer care and strive for excellence in service delivery. Please reach out for more information or a personalized quote.

Contact us

Product related to fossil fuel power plants

Select the product and learn more about its benefits

|

Modular Air Cooled Condenser Metal Works Module Air ACC is an innovative modular air-cooled condenser (ACC) that directly condenses steam turbine exhaust fow and return condensateto the boiler without any water loss. With construction savings of up to25%, compared to a standard A-frame, construction time can bereduced by several months for large power plants. |

|

|

W-style Air Cooled Condenser Metal Works W-Style ACC is an innovative Induced Draft Air-Cooled Condenser(ACC) directly condensing the steam turbine exhaust fow. The condensate returns to the boiler without any water loss. With its unique "W" heat exchanger structure, the amount of steel and overall height of the ACC are dramatically reduced. This is useful for all powerplant applications. |

|

|

Box Air ACC is an innovative Induced Draft Air-Cooled Condenser (ACC), suitable for all power plants ranging from 1 to 30 MWe. This ACC type consists of standard boxes that are easy to assemble and that offer a short delivery schedule and high reliability level. Box Air ACC is used in waste incineration plants, biomass, solar and geothermal power plants and is suited as a capacity increase of an existing power plant. |

|

|

Hexagon Air Cooling is a standardised, modular air-cooled condenser (ACC) which is easy to build and robust in performance. lt is used in waste-to-energy, biomass, small size electrical power plants and industrial co-generation.Hexagon Air Cooling induced draft configuration saves up to1 5% fan power consumption. |

|

|

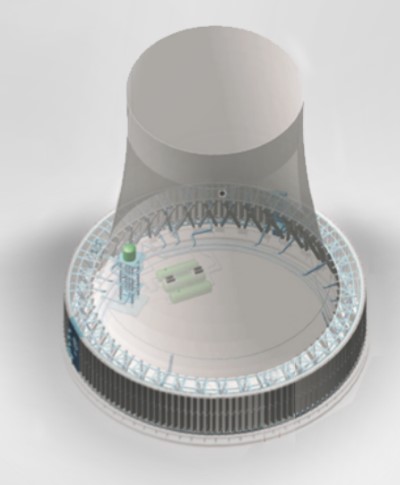

An Indirect Dry Condensing system connects an Indirect Dry Cooling tower (lDCT) with a steam surface or jet condenser. lts tall concrete orsteel shell eliminates hot air recirculation. Indirect Dry Cooling solutions offer a reduced maintenance and are suited for largecapacity condensing units. |

|

|

Air-Cooled Heat Exchangers (ACHE) are custom designed heavy-duty fin tube heat exchangers. They allow the direct cooling by air ofvarious process mediums.ACHEs are used in applications in manyindustries, such as power, chemical, ORC plant, Oil & Gas, steel andseveral other industries |

|

Questions about Air Cooled Condensers?

Interested in learning more about air-cooled condenser solutions? Share your project request and we’ll get in touch with you very soon!

Contact us

Why ZHM Huawu Metal Hexagon Air Cooled Condensor Tower Structural Works ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Hexagon Air Cooled Condensor Tower Structural Works ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com