Corten Steel Production for Cladding, roofing, facades, and sculptures,Bridges, building frameworks

Corten Steel Production for Cladding, roofing, facades, and sculptures,Bridges, building frameworks

Civil structures, load-bearing structures, and general outdoor construction components and parts are made from corten steel since they can withstand and remain durable in harsh environmental conditions.

The material can last a long time.

Its ability to last for years and in some cases, decades, when exposed to outside elements is largely due to its capacity to regenerate a protective and highly corrosive-resistant coating within a few months to a few years of exposure.

This occurs without having to go through wet and dry weather cycles typically required by other types of non-alloy metals.

The information on corten steel provided below will be particularly relevant for businesses which require metal parts that will be used in outdoor construction and architectural projects.

The specific topics that will be covered include how it is made, its unique physical properties, the advantages, and disadvantages of using it for metal parts.

Some of its more common industrial applications and uses will also be listed.

What Is Corten Steel?

Corten steel is a group of combined steel alloys that exhibit a high degree of corrosion resistance and tensile strength.

It was developed and introduced in the 1930s by the U.S. Steel Corporation (USS) to assist in the development of railroad coal wagons.

While typically written as corten, the official trademark name is COR-TEN, which refers to its specific qualities and properties, namely:

COR: Corrosion-Resistance

TEN: Tensile Strength

The alloys which make up corten are primarily copper and chromium.

The way they are combined allows the steel to retain a high degree of strength and create natural rust (patina) that protects it from atmospheric elements that commonly cause corrosion and structural damage.

The rust-coating it develops also gives it a natural-looking and ruggedly beautiful appearance.

Its anti-weathering, high-strength, and aesthetically pleasing properties make it an ideal metal for outside construction and landscaping projects.

These same properties also diminish the need for regular maintenance and painting—once a project is completed, it can usually be left alone for years without any additional work needing to be done to it.

How Is Corten Steel Made?

The corten steel manufacturing process begins with a blending of three primary plates of steel—copper, chromium, and nickel—along with other alloying elements like phosphorus, silicon, and manganese.

Very little carbon is used during the mixing process—less than 0.2-0.3 percent—to ensure pliability, strength, and toughness.

Combining these specific metals and elements results in a 1/4th inch thick sheet that is ductile enough to be formed into almost any desired shape.

The real magic of the corten steel process, however, occurs after the initial mixing takes place and during its natural weathering cycle.

Corten Steel Weathering Process

Alloy steels and other structural steels tend to rust when they are exposed to moisture and air.

The rusting of structural steel is usually porous (full of holes) and often detaches from the metal surface, causing the process to occur repeatedly, at a significantly higher rate each time.

With corten steel, the rusting process begins in the same way but instead creates a layer of stable rust (i.e., patina) that adheres to the metal instead of detaching from it.

This helps reduce the number of porous gaps within the metal and also reduces the amount of oxygen and moisture which often penetrate those gaps, thus eliminating further rusting.

The result of corten steel’s weathering process is a stronger and less-corrosive structure that requires less upkeep than other structural metals can normally provide.

Corten Steel Patina Timeline

Several factors affect the time it takes for the protective patina to form on corten steel.

The specific environment, humidity, and the distance between moisture particles affect the rate at which the patina is formed.

One thing is for sure, though: the more environmental cycles that corten steel is exposed to, the quicker it will form the desired protective rust on its surface.

For those who don’t want to wait for wet and dry environmental cycles of the weather, saltwater can be used to speed up the process.

Simply spray the saltwater across all sections of your corten steel panels and repeat the process every day until an even orange color appears across the entirety of their surface.

You can expect to see the patina forming in as little as a month (2-3 months is standard), depending on the amount and size of panels you are using.

How Do You Weld Weathering (Corten) Steel?

Two kinds of welding procedures are used for corten steel: metal inert gas welding and arc welding.

MIG welding uses an electric arc and filler wire to join two pieces of corten steel together.

The electric arc flows between corten metal and the filler wire while producing enough heat to melt and join them together.

Arc Welding

The arc welding process is a bit trickier and more complicated than MIG welding.

While an electric arc is also used in arc welding to run heat between a filler electrode and corten steel, the welder must hold the electrode and torch simultaneously so that the arc can melt the materials together.

Arc welding requires more manual labor than metal inert gas welding.

However, it also offers more flexibility, as different sizes (thickness) of corten steel can be welded without having to adjust the electrodes or change the general process in any way.

Choosing the Right Materials for Welding

Whichever welding process is used, filler metals must be chosen cautiously for both technical and safety precautions.

This is because the final product will most likely be used for private and public structures and other service-related applications.

First, the following design requirements need to be considered:

What are the current local welding codes and specific design requirements?

How strong and tough does the steel need to be to fulfill application requirements?

Where is the welded corten steel going to be situated? What level of corrosion resistance will it need to provide to handle environmental conditions?

What is the required weld size?

What is the required joint geometry?

Are there any specific color schemes that need to be followed?

Aside from these considerations, national steel welding codes must also be adhered to when welding corten steel.

The two most common steel welding codes in the U.S.A. include the American Welding Society (AWS) D1.1 and D1.5.

Both these codes provide guidelines for all the appropriate uses of corten steel and the welding methods that should be used for the structure being built and the environment it will be located in.

As was discussed earlier, the unique property that separates corten steel from other steels is its weathering capability.

Weathering (corten) steel naturally undergoes a chemical process that creates a new surface composition that offers more atmospheric-corrosion protection than other steels can provide.

In other words, the unique composition and distribution of alloying elements within corten steel form continuous self-regenerating rust that protects the surface from oxidation and corrosion.

Aside from its weather-resistant property, weathering steel also provides the following properties:

Paint Durability— While many manufacturers prefer corten’s rustic look as it is, it can be painted in the same manner other steels are painted in, but it requires a less frequent repainting cycle due to its lower rust rate.

Weldability—Since it has a low carbon content, the steel remains pliable enough for welding.

Workability—Corten steel can be cold-formed, hot-formed, and gas-cut, making it easy to work with no matter what the project requirements are.

Reliability—It displays 2-8 times more anti-corrosive resistance than regular steel, it is 1 ½ – 10 times more paintable than common carbon steel, and has a tensile strength of no less than 445 MPa, making it a high-performance, long-lasting material for steel parts.

As you can see, such qualities are particularly useful for outdoor projects.

It should be noted here that weathering steel comes in two grades – Corten A and Corten B – which to a larger or lesser extent exhibit some or all of the above properties.

Corten A

This version contains added phosphorus making it more suitable for flue gas applications.

Corten A is not recommended for heavy-load bearing applications as the added phosphorus reduces its tensile strength.

Corten B

Corten B is the more common of the two kinds.

It is the one that forms the protective rust coating and maintains a high degree of tensile strength along with enough malleability for welding.

Corten B is especially useful for steel parts needed for heavy, load-bearing structures situated in harsh outdoor environments.

Depending on your specific requirements, your metal manufacturer will guide you as to which of the two versions is best suited for your particular project.

Advantages of Using Corten Steel

Weathering steel’s anti-corrosive properties are what separates it from other steels and make it a better choice for outdoor metal parts and structures.

Its natural-forming rust can lengthen the life cycle of any structure and so reduce maintenance and replacement costs.

Nevertheless, these are not the only advantages to using corten steel.

Below you will find a list of major benefits provided by this unique metal alloy.

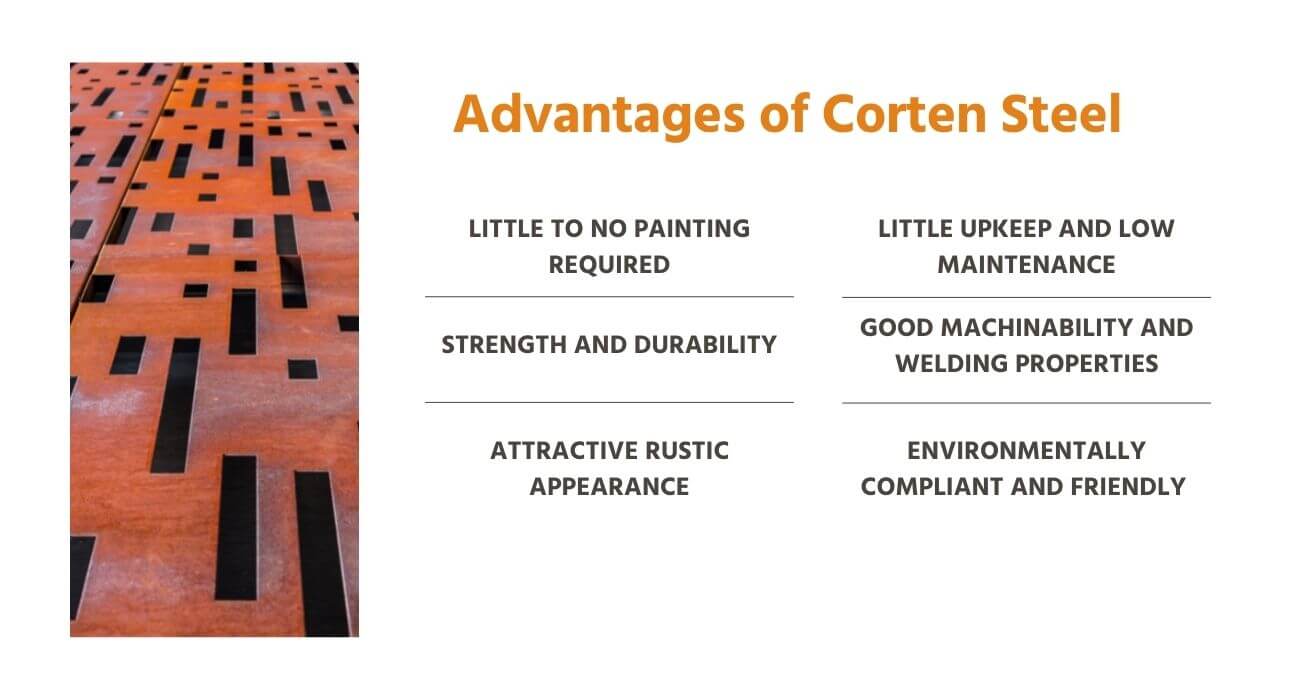

Little to No Painting

The patina that forms on corten weathering steel reduces, and in most cases even eliminates, the need for paint.

This not only helps cut down on maintenance and material costs but also helps to avoid using dangerous and volatile compounds found in some paints.

Strong and Durable Material

Corten’s high tensile strength and durability (Corten B) make it very useful for heavy-duty, load-bearing structures.

Weathering steel is four to eight times more durable than traditional steel.

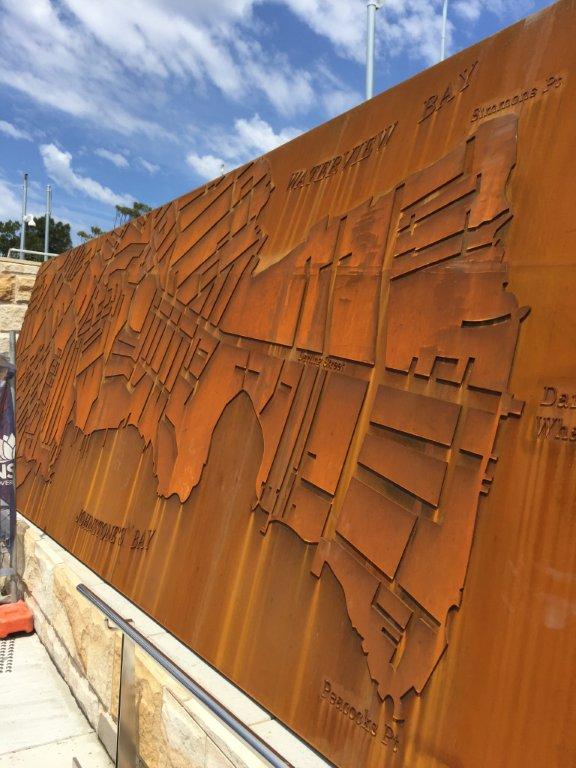

Attractive Rustic Appearance

The reddish-brown rust that naturally forms on its surface makes it a popular choice among architects and design engineers who work with artistic and contemporary structures and applications.

Very Little Upkeep and Maintenance

Due to its chemical composition, corten steel can withstand wet and moist climates and heat that would cause corrosive damage to other forms of steel.

Corten’s melting point is around 1450-1510 degrees Celsius.

Structures made from corten weathering steel can maintain their integrity for many years. Little to no maintenance is required, which also means less money is spent on upkeep.

Good Machinability and Welding Properties

Corten steel retains a high degree of flexibility despite it being so sturdy. This means that it can be cut, shaped, curved, and welded to customized specifications.

Weathering steel can be cold and hot-formed, gas-cut, and welded utilizing almost any type of welding method in use today.

Environmentally Compliant and Friendly

Since it is made of ecological materials that are 100% recyclable, it remains in compliance with most structural standards and codes.

Therefore, it offers an attractive option for those looking for environmentally-friendly building material.

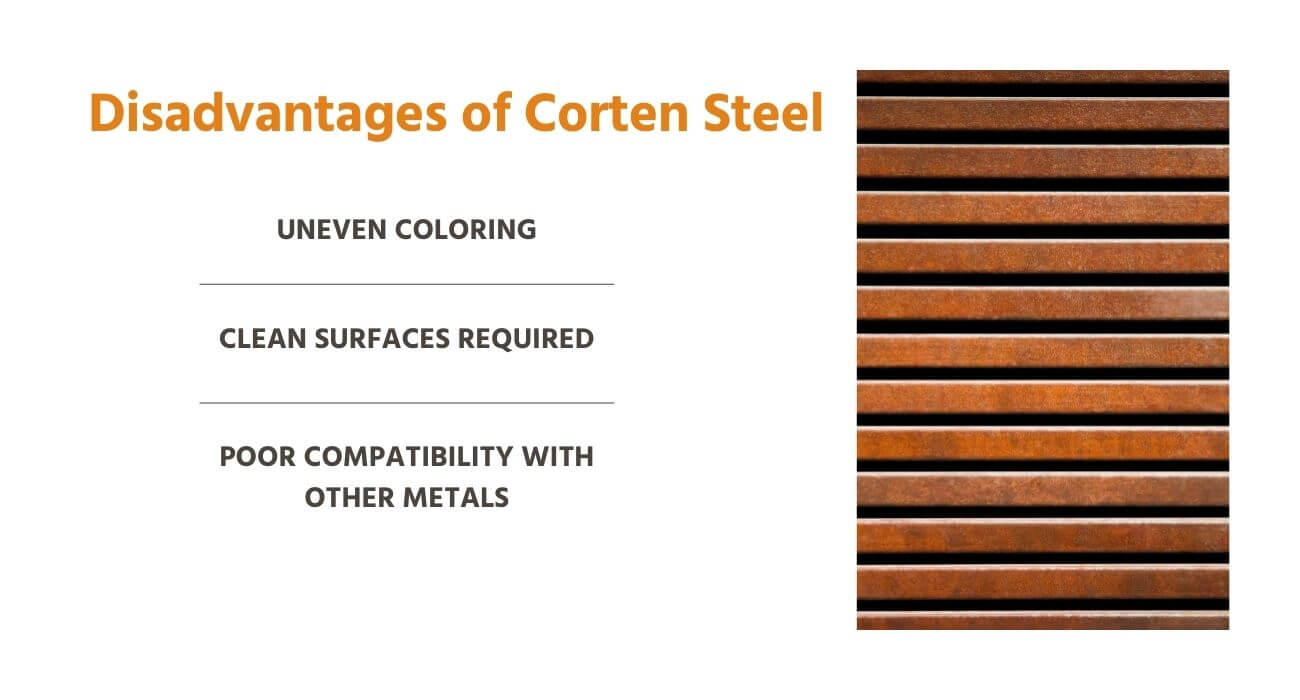

Disadvantages of Corten Steel

Since corten weathering steel has so many advantages, it would seem like it is an ideal building material for just about any outdoor project.

However, some factors should be considered before choosing it for your next project.

For one thing, certain environmental conditions, such as high-chlorine environments, can reduce its corrosive-resistant and durability properties.

disatvantages of corten steel

Also, wet environments, especially those located underwater, can impede its corrosion-resistant capabilities.

Some of the other disadvantages of corten steel are as follows:

Uneven Coloring

While corten’s rust color tends to be an even orange-brown, there are no guarantees that it will stay that way over time.

This could pose a big challenge should a portion of a panel need to be replaced, and an exact match color reformed.

Clean Surfaces Required

Aside from chlorine, other substances can interfere with weathering steel’s oxidation (rust-producing) process, such as oil, grease, cement, mud, and mortar.

Therefore, corten steel must constantly be kept clean so that it does not come into contact with such agents.

Poor Compatibility

Corten steel does not always work well with other metals, especially when they are situated in certain types of environments.

Galvanic corrosion often occurs when two metals with different electrolytic properties and potentials are combined in the presence of water.

Oftentimes when such problems occur, extra material is needed, such as waterproof fasteners and nylon spacers to avoid the two different metals from touching each other.

Corten Steel Uses and Applications

Corten steel is widely used within the building and construction industry for large-scale projects as well as with medium to smaller projects where a high level of aesthetics is required (i.e., architecture, sculpture, home and garden).

A summary of its more popular applications is given below:

Building & Architecture: outdoor load-bearing buildings, bridges, and ships, as well as architectural structures of an aesthetic nature, such as beach homes and museums.

Art, Sculpture, & Garden Design: outdoor art projects, especially those that include sculptures, as well as landscaping and garden structures exposed to damp and moist environments.

Visual Screens: cladding material for surrounding, dividing, and protecting structures like fences, gates, and wall panelings.

Aside from the above common uses, corten weathering steel is also utilized to create lesser-known and uncommon outdoor structures and applications.

These include:

Micro-Homes

Broadcasting/Transmission Towers

Railway Electric Cars

Chimneys

Outdoor Log Burners

Lawn Edging

Garden Stairways

Outdoor Lighting & Water Fixtures

Outdoor & Indoor Wood Storages

Cycle Hoops

Tree Grilles

As can be seen from the above lists, weathering steel is a flexible material that can be used for large-scale construction projects, as well as medium-sized art and sculpture designs.

It is equally suitable for public service applications, and small and personalized home and garden hobbies.

Conclusion

Corten weathering steel is best known for its atmospheric corrosion-resisting properties.

Those properties result from a natural and automatic protective layer of rust that forms on its surface when exposed to the elements.

Aside from its rusting capabilities, it also comes with a high degree of tensile strength, weldability, and machinability properties.

That makes it a good fit for large outdoor construction and architectural projects.

Its rustic appearance is also prized by artists, sculptures, architects, and design engineers who need a natural-looking material for their work.

If you are looking for a corrosive-resistant, high-strength, and flexible material that is easy on the eyes, does not require a great deal of upkeep and maintenance, while being environmentally friendly and compliant, then corten steel is your best bet.

Contact ZHM Today

For further information about our machining and metal surface treatment capabilities, contact us directly via the convenient website form or request a quote here. We welcome your inquiries.

Corten Steel

ZHM offer expertise in Corten Steel combined with a complete package of fabrication, laser cutting, bending and assembly. Due to our extensive manufacturing capabilities, including 28,000 sq meters of manufacturing space, we offer complete flexibility and quick turnaround.

We supply Corten Steel in the following sizes:

Thickness: 0.5mm-40mm

Width: up to 3330mm

Length: Up to 15000mm

What is Corten Steel?

Corten Steel (Cor-ten®) is a low-alloy, high-strength outdoor steel and is one of the groups of ‘Weathering Steels’ developed for its superior resistance to corrosion. It is designed to develop a rusty appearance once left to weather, which reduces the need for painting.

The rust that develops seals the surface by creating a protective layer preventing further corrosion and reduces the amount of glare which can be found on standard metals. This process reduces the amount of maintenance which is required whilst simultaneously increasing the life span of the material.

Alloyed with nickel, copper and chromium, this increases the strength and corrosion resistance. Originally used in USA in the 1930’s for coal carriages, Corten is now used in a variety of different outdoor applications. Within architecture it can be incorporated into many designs such as buildings, roofing, bridges and sculptures.

The oxidisation process which develops on Corten Steel, occurs when the material is subjected to the alternating wet and dry conditions which exist outdoors. Over time, the rust layer develops into a patina layer changing the colour from orange to dark brown through continuous regeneration promoting resistance to corrosion.

The entire oxidisation process can take between 4-10 years, however more frequent wet and dry cycles will speed this process up. Whilst the Corten steel doesn’t prevent rusting, it will reduce the amount of corrosion when applied correctly.

What are the benefits of Corten Steel?

Corten Steel has many benefits including maintenance and longevity. Alongside high-strength, Corten is a very low maintenance steel which is ideal for structures where maintenance can be difficult or dangerous such as bridges, or where disruption needs to be minimised such as around major roads or railways.

Corten can be constructed more quickly than other types of steel since processes such as painting can be eliminated. The rust appearance which develops on Corten Steel can increase the longevity of the application given the resistance to corrosion therefore creating a more economical solution.

Why ZHM?

ZHM is the partner of choice for in China for Construction Companies, Landscaping Companies and Architects, given the unrivalled manufacturing capability. We continuously upgrade our machinery which ensures the highest quality product for the best possible price. As everything happens under one roof, this means faster lead times and reduced transportation costs.

We undertake a wide range of projects across different industries and we are happy to provide quotations for all work. From start to finish ZHM provide a fully comprehensive service.

For any Corten Steel enquiries or if you require any further information please call us on +86-135-88151981 or send enquiries to zhmhdss@foxmail.com

Corten steel (or COR-TEN) eliminates the need for painting or coating the metal by creating a stable rust-like appearance which develops over time from exposure to weather, a solution which can considerably extended the lifespan of the metal.

The uses and applications of Corten steel are diverse and innovative – from garden planters and lawn edging to building cladding and roofing. Sheet Corten steel can be laser cut into intricate designs to make for beautiful artworks and distinctive screens.

The typical surface oxidation of weathering steel takes approximately six months, but surface treatments can be applied which accelerate the oxidation with the rust-like coating developing in a few hours.

The layer protecting the metal’s surface develops and regenerates continuously when subjected to the weather – in other words, the steel is allowed to rust in order to form the protective coating.

Unlike rust, the weathered surface of Corten steel does not flake or transfer off the metal when touched or rubbed making it a clean and very attractive solution.

The name Corten refers to the two distinguishing properties of this type of steel: corrosion resistance and tensile strength.

We can manufacture a range of items using Corten or simulated Corten in conjunction with a range of different materials...

As you can see, this specialty steel will continue to patina over time, aging to a beautiful dark mocha hue. Eventually, it will look more like metal instead of showing off the bright yellow or orange colors that it started with.

If you choose to stop the patina process, you can do this quite easily! Simply apply a protective, clear-coat paint to the surface of your corten steel fire pit. This will also alleviate the "rust" layer of residue.

Corten Steel Panels

Your decades-long partner for top-quality corten metal steel panels in Australia.

ZHM has been offering a wide service range of diverse structural steel requirements for Global clients for three decades. Among our most significant productions are high-tensile strength corten steel panels for any size of structural projects, may it be a massive wall or a tiny garden planter for your landscape design completion.

Basics on Corten Steel

Weathering steel, most commonly known as corten steel, has made its mark way back in the 1930s when it is mostly utilised for rail cars. It has evolved and is now often incorporated for large outdoor structures, such as bridges, roofs, and walls.

Corten steel panels are also popular because of their unique appearance, usually golden brown and dark orange, perfect for diverse weather conditions. A rustic layer will eventually coat the surface over time, thus giving it its unique and attractive colour. The stable rustic coat suitable for any weather conditions sets corten steel panels apart from thin and mild steel.

This “rusting” quality of corten steel is unlike standard steel, which doesn’t protect or seal the surface but will eventually flake. As for corten steel’s rusting process, this is a natural part of creating that protective layer. That is why corten steel for a garden edge is as attractive-looking as it is reliable in strength and longevity.

Business owners often opt for corten steel panels since installing them will not require you to paint your projects’ surfaces repeatedly.

Why Choose Us?

For your projects requiring advanced engineering, most especially when they are complicated and in need of intricate detailing, our team at ZHM is always up for the challenge. Along with our top-notch product designs and skilled staff, we manufacture our metal materials using only best-in-class equipment.

Our team of experts will fully coordinate with you for any of your design specifications to ensure that your concept is brought to life precisely. As a metal folding shop servicing for decades, we have been able to leave long-lasting impressions to our clients since we thoroughly invest in every project we make, from designing to installing structural and other artistic features.

What We Offer

Our services indeed come with aesthetic designs, and we also make sure that they can withstand possible wetting and heating problems due to a mixture of weather conditions, particularly rusting on the corten steel panels that we produce.

ZHM is also one of the largest processors of corten metals in China, offering our varied metal structure services to different clients, including architects, government agencies, and other establishments requiring solutions for their complex engineering design needs.

With us, you will be relieved of the hassle of typing “corten steel fabricators near me” into the Google search box. We are a very accessible and one-call-away metal shop here in China!

Our corten steel panels are suitable for any establishments and other ornaments you aim for your landscaping project. The thickness range of our unique corten materials in stock is from 3 mm to 30 mm. Other services we offer include wall cladding, landscaping, creating water features, fire cauldrons, and planters.

Aside from these product features, we guarantee you excellent durability for all our panels. It goes without saying that we manufacture them by considering how important it is for our customers to make informed and long-term investments.

The corten steel panels you will purchase are perfectly made for outdoor use, thus assuring you that they increase tensile strength over time as they are repeatedly exposed to its environment’s ever-changing atmosphere.

When you partner with us, not only are you assured of long-lasting metal products, but you will rest easy knowing that we produce everything with accuracy and precision. This means that we take pride in delivering the corten steel panels you need with a faster turnaround time. As master tradesmen, we fully consider how time is of the essence for any establishment.

Special Feature Doors Staircases Art and Wall Feature Panels Laser Cut Panels Full Range of Planter Boxes Garden Edging Water Features Cladding Systems

Turn Your Creative Concept into a Reality!

When it comes to your corten steel panel needs, ZHM has got what you’re looking for. Be it having unique and attractive corten steel planters in China for your gardening project or landscaping ornaments or needing sturdy corten steel panels for your roof buildings and other wall establishments; we have it all covered.

If you ever find yourself seeking only the best fabricators of corten metal steel here in the world, established and consistent in delivering high-quality products and services, stop by ZHM. We make sure that our expert advice heightens your creative imagination. Feel free to connect with our crafty staff today for further information on our available corten steel panels.

In the realm of modern architecture and design, Corten Steel has experienced a remarkable resurgence, captivating the imagination of architects, artists, and designers alike. This renaissance has brought about a profound transformation in metal fabrication, redefining its role in contemporary projects. This comprehensive article will delve into the various facets of Corten steel fabrication, exploring its diverse types, intricate processes, associated challenges, and the latest trends that have propelled it to the forefront of modern design. Additionally, we will shed light on the critical aspects of material selection for multifaceted applications across industries and examine why Corten Steel is undergoing a renaissance in contemporary design.

CORTEN STEEL: AN INTRODUCTION

Corten steel, often called weathering steel, is a group of steel alloys renowned for their propensity to develop a rust-like patina when exposed to the elements, especially in outdoor environments. This unique characteristic imparts a distinctive aesthetic quality and bestows exceptional corrosion resistance upon the material, rendering it a favored choice for architectural and structural applications. Corten Steel’s rich, earthy tones and textured surface have made it a favorite among architects and designers seeking to seamlessly blend the industrial with the natural world.

VARIETY OF CORTEN STEEL FABRICATION METHODS

The Corten steel fabrication encompasses many processes and techniques, each tailored to breathe life into unique designs and functional components. Here, we explore some of the most common forms of Corten steel fabrication:

CORTEN STEEL SCULPTURES

Description: Corten steel serves as the canvas for artists and sculptors, resulting in breathtaking sculptures. The natural rusted patina adds depth and character to the artwork.

Advantages: Weather resistance, durability, and an evolving aesthetic.

Applications: Public art installations, private collections, and urban landscapes.

CORTEN STEEL CLADDING

Description: Corten steel panels are employed to clad building exteriors and interiors. The weathered appearance imparts a sense of timelessness to modern architecture.

Advantages: Corrosion resistance, low maintenance, and design versatility.

Applications: Facades, interior walls, and roofing.

CORTEN STEEL STRUCTURAL COMPONENTS

Description: Corten steel finds its place in the construction of bridges, buildings, and other structural elements. Its robustness and resistance to corrosion make it ideal for heavy-duty applications.

Advantages: High tensile strength, durability, and reduced maintenance costs.

Applications: Bridges, architectural frameworks, and industrial structures.

CHALLENGES TO CORTEN STEEL FABRICATION

While Corten steel boasts numerous advantages, it also presents unique challenges during the fabrication process:

Rust Management: Effectively controlling and managing the rusting process to achieve the desired appearance without compromising structural integrity can be a nuanced endeavor.

Welding Considerations: Specialized welding procedures and consumables are requisite to ensure that the welded joints exhibit corrosion resistance commensurate with the base material.

Design Precision: Attaining intricate designs and complex shapes can pose challenges, as Corten steel’s natural weathering process may have an impact on precision over time.

Initial Cost: Corten steel is generally associated with a higher initial cost than standard carbon steel, potentially affecting project budgets.

The resurgence of Corten Steel has been driven by architectural innovation and evolving design trends. Here are some of the current trends that have propelled Corten Steel to the forefront of modern design:

Digital Fabrication: Adopting digital fabrication technologies, such as CNC plasma cutting and 3D modeling, has streamlined the manufacturing process. This enables precise cuts and complex shapes, allowing manufacturers to achieve intricate designs efficiently.

Automation: Manufacturing facilities increasingly incorporate automation, including robotic welding and material handling systems. This boosts efficiency and ensures consistency and precision in Corten steel fabrication.

Sustainability: Sustainability is a driving force in modern manufacturing. With its long lifespan and minimal maintenance requirements, Corten Steel aligns with eco-friendly manufacturing practices. Recycled Corten steel is also becoming more prevalent, further reducing environmental impact.

Customization: Manufacturers offer customized Corten steel solutions to meet specific project requirements. Advanced machinery allows for intricate designs and tailored solutions, catering to each customer’s unique needs.

Lean Manufacturing: Lean manufacturing principles are applied to Corten steel fabrication, optimizing processes and reducing waste. This approach enhances efficiency and cost-effectiveness while maintaining high-quality standards.

Collaboration: Collaboration between architects, designers, and manufacturers has become crucial. Manufacturers work closely with design professionals to translate creative visions into Corten steel components, ensuring a seamless integration of art and functionality.

Stack of Corten Steel Beams

MATERIAL SELECTION AND ITS MULTIFACETED APPLICATIONS

Corten steel’s exceptional properties make it suitable for various applications across various industries. Here are some illustrative examples that showcase its versatility:

INDUSTRY APPLICATIONS

Architecture Cladding, roofing, facades, and sculptures

Construction Bridges, building frameworks, and structural elements

Landscaping Garden features, retaining walls, and planters

Interior Design Wall panels, partitions, and decorative elements

Art and Sculpture Outdoor and indoor sculptures and installations

Corten steel’s natural rusted appearance, durability, and corrosion resistance make it a preferred choice in architectural and design projects. Whether adorning a contemporary building facade, enhancing the beauty of a landscaped garden, or serving as the canvas for a sculptor’s imagination, Corten Steel’s applications are as diverse as they are awe-inspiring.

CORTEL STEEL VS. MILD STEEL VS. STAINLESS STEEL | A COMPARATIVE STUDY

The following table summarizes the comparison between three different steel vis-a-vis their application and properties, which can help you make a selection:

| FEATURE/TYPE | CORTEN STEEL | MILD STEEL | STAINLESS STEEL |

|---|---|---|---|

| Composition | Steel alloys with copper, phosphorus, nickel | Carbon steel with low carbon content | Steel alloy with at least 10.5% chromium content |

| Corrosion Resistance | High (develops protective rust layer) | Low (prone to rust) | Very High (resists staining/rusting) |

| Weldability | Good | Excellent | Good (specific grades might require pre/post treatment) |

| Formability | Good | Excellent | Good |

| Tensile Strength | Medium-High | Medium | Medium-High |

| Cost | Medium-High | Low | High |

| Maintenance | Low (weathered appearance is desired) | High (needs painting or finishing) | Low (resists corrosion and staining) |

| Weight | Medium | Medium | Medium |

| Manufacturing Processes | Welding, forming, cutting | Welding, forming, cutting, bolting | Welding, forming, cutting, polishing |

| Applications | Architectural cladding, sculptures, bridges | Structural frames, car bodies, machinery | Kitchen equipment, architectural panels, medical devices |

CONCLUSION

Corten steel fabrication has ushered in a new era of design possibilities in architecture, construction, landscaping, and art. Its distinctive aesthetics, inherent durability, and corrosion resistance have elevated Corten steel to prominence in modern design, captivating the imagination of creatives worldwide.

Corten Steel: Everything You Need To Know For Your Garden

Do you always worry about your garden ornaments and outdoor sculptures rusting and deteriorating in the process? What if you could use a material that forms rust but protects the structure instead of destroying it? Yes, that kind of metal exists! It’s called Corten steel or weathering steel.

Corten steel is the name for the commonly seen ‘rusted’ steel alloy seen in both modern metal art and architecture. Its surface forms a protective oxide layer when exposed to the weather, keeping the metal strong and protected. This means it has excellent corrosion resistance as well as an attractive appearance.

The protective layer of Corten steel keeps on regenerating over years of exposure to weather. Over time, the steel forms a stable rust-like appearance. This iconic weathered look and rusty orange colouring make it popularly used in outdoor sculptures, metal garden art, rustic planter boxes, rustic garden edging, as well as in bridges and other large structural applications.

Would you like to use Corten steel in your next project? Read on to learn more about Corten steel, its rusting process, the pros and cons of using it, how to maintain it and other useful facts.

Table of Contents

What Is Corten Steel?

Corten steel is a type of steel alloy designed to naturally generate a rust-like patina, while creating its own protective outer layer. Corten steel is the shorthand for weathering steel that creates a rust-like look after years of weathering, without the structural weakening associated with rust.

What Is Special About Corten Steel?

What Is Corten Steel Made Of?

How Thick Is Corten Steel?

Pros & Cons Of Corten Steel

Pros Of Corten Steel

Cons Of Corten Steel

Cost of Corten Steel FAQs

How Much Does Corten Steel Cost?

Is Corten Steel Expensive?

Corten Steel & Rusting FAQs

How Long Does Corten Steel Take To Rust?

Does Corten Steel Stain Concrete?

Can You Keep Corten Steel From Rusting?

Sealing & Maintaining Corten Steel

Can Corten Steel Be Sealed?

How Do You Maintain Corten Steel?

Is Corten Steel Sustainable?

Is Corten Steel Recyclable?

Is Corten Steel Safe For Vegetables?

Where Can I Buy Corten Steel In Australia?

Corten Steel Metal Art

What Is Corten Steel?

Corten steel is a type of steel alloy designed to naturally generate a rust-like patina, while creating its own protective outer layer. Corten steel is the shorthand for weathering steel that creates a rust-like look after years of weathering, without the structural weakening associated with rust.

This product was originally designed to help build railroad coal wagons, and its success led to its use for outdoor sculptures and architecture. The rusting or weathering process of Corten steel is what makes it special. It does not prevent rusting, but it forms rust only on its outer surface for protection. The presence of chromium, copper and nickel improves the Corten steel’s weather resistance, allowing the development of a desirable patina.

Corten is known for its superior corrosion resistance (COR) and tensile strength (TEN), two distinct characteristics from which the name is derived. When exposed to weather, it forms a protective oxide layer of rust. The beautiful colour created by the natural rusting of the metal means that no paint has to be used to create rich, earthy looks in the metal that continues to grow every year. In addition, this layer of rust completely protects the raw steel underneath it.

What Is Special About Corten Steel?

When exposed to the environment, Corten steel forms a patina or an outer layer of rust because of oxidation over a long period. Instead of deteriorating the metal, the oxidised dark brown coating acts as a barrier, prevents any deeper rust penetration and protects the metal from further corrosion.

Every time the steel is rained on or endures any moisture, the rust layer thickens. After several years, the rust layer will stabilise and form a natural look that other metals need fake paint and finish to achieve. This barrier means you won’t need to do any upkeep for the outer rusted layer or the steel within, unlike other types of steel which need ongoing maintenance. The rust forming on the surface of Corten steel is a naturally rusted surface that changes in colour and pattern and ripens with age, giving the steel an aesthetically pleasing look. This means that when Corten steel is your material of choice, it makes it very easy to maintain outdoor metal art without deterioration. For that reason, Corten is a popular choice for garden edging, planters and other backyard fixtures.

What Is Corten Steel Made Of?

Corten steel is a copper chromium alloy steel that is added with phosphorus and nickel-molybdenum.

The two common types of Corten steel are Corten A and Corten B. Corten A is lower in carbon, manganese and silicon while being more phosphorus, copper and chromium dense. This composition makes it ideal for aesthetic fascias and outdoor sculptures. Corten B has more carbon and manganese in comparison, and has a lower percentage of phosphorus, making it ideal for heavy and load-bearing structures, commonly seen in the construction industry.

How Thick Is Corten Steel?

The thickness of Corten steel largely varies according to type. Corten A, which is typically produced as a coil or sheet, has a thickness ranging from 1 mm to 12 mm. Corten B, which is commonly produced as a plate, is thicker at about 15-50 mm thickness.

Pros & Cons Of Corten Steel

Corten steel is found around the world in various different applications because it’s extremely versatile. Corten’s unique benefits make it a great choice both functionally for construction, and visually for outdoor metal art and facades.

Although it’s not without its downsides, the sheer amount of Corten steel found in modern architecture and construction shows that the positives often outweigh the negatives.

Pros Of Corten Steel

Using Corten steel has the following advantages:

Durability – Corten steel is a durable type of metal that can last for decades, depending on where it is and how it’s finished.

Anti-corrosive Properties – The developing rust layer that forms over the Corten steel will help provide corrosion resistance.

Highly Resistant To The Weather – The prolonged exposure of Corten steel to harsh environmental and weather results in the formation of rust that acts as a protective coating. It prevents corrosion and deterioration of the material by allowing rust to dry quicker and thicker and then developing a beautiful patina.

Protective Self-regenerating Surface Layer – The layer protecting the surface develops and continues to regenerate when subjected to the weather.

Distinct Rust-like Appearance That’s Great For Aesthetics – Corten steel or weathering steel often blends well with the environment, and its appearance even improves with time. Its distinct appearance makes it ideal for many types of sculptures, architecture, or landscaping work.

Low Maintenance Requirement – The rust formation seals the surface and creates a protective layer. It also reduces the amount of glare that’s common on standard metals. As a result, the amount of maintenance needed becomes reduced. You only need to clean and inspect Corten steel products or structures. Cleaning means rinsing the rusted surface with water to remove any natural debris or contamination.

Cost-effectiveness – Corten steel may be more expensive than mild or ordinary steel to initially purchase, but you will spend less money on maintaining it; making it more cost effective in the long run.

Environmentally Friendly – Corten steel is an environment-friendly option that’s sustainable and recyclable.

Cons Of Corten Steel

Below are the drawbacks to using Corten steel.

Retention Traps – The disadvantage of using Corten steel or weathering steel is that it’s not 100% rustproof. If used in buildings and water accumulates in its pockets, these areas may have higher corrosion rates because continuous damp or wet conditions prevent the oxides to crystallise. The potential to trap moisture means you should be careful how you hang metal wall art outdoors.

Staining – The initial surface weathering of Corten steel may cause rust staining on nearby surfaces. This can be avoided by using designs that drain loose rust products onto neighbouring surfaces. Choosing the right metal art design will help mitigate this risk.

Compatibility With Climates – Corten steel is not compatible with all climates. It is sensitive to humid climates. In these areas, the protective patina may not form properly, and the steel may continue to corrode.

Welding Technique – Welding Corten steel requires similar precautions as when welding mild steel. It can be welded manually and mechanically, but the difference is the need for a special filler material to produce the weathering steel weld in some cases. To get identical mechanical properties in the weld and in the base material, suitable welding consumables and welding conditions must be used.

Cost of Corten Steel FAQs

Corten steel is more expensive than common steel. Its cost depends on different factors, like the dimensions of what you want to buy.

How Much Does Corten Steel Cost?

The cost of Corten steel on average is between $35 and $70 per square metre. However, the cost of Corten steel depends on a variety of factors, including the amount, length and weight of the steel you’re buying. The greater the dimensions are, the higher the price is.

Is Corten Steel Expensive?

Yes, Corten steel is more expensive than other common grades of steel. Depending on the application, pieces fabricated from Corten steel can cost between 50% and 300% more than mild steel. However, the unique appearance of Corten means many people are willing to pay a premium to get the aesthetic they prefer.

If Corten steel is out of your budget, there are some Corten steel alternatives that may also be suitable for your project.

Corten Steel & Rusting FAQs

How Long Does Corten Steel Take To Rust?

Under normal conditions, and if the surface is alternately wet and dry, the patina forms and matures within 18-36 months. Some weathering steel can even form a patina between 6 months and 1 year. However, the entire process can take between 4-10 years.

Patina forms consistently when the Corten steel is subjected to alternating wet and dry periods. The rusting or weathering process depends on the aggressiveness of the environment into which the Corten steel is placed and the frequency of the wet and dry cycle.

How Can I Speed Up Corten Steel Rusting?

The more frequent the wet and dry cycle is, the quicker Corten steel will rust. To quicken its natural ageing or rusting process, more frequent wet and dry cycles are needed. Spraying saltwater or a mixture of salt solutions mixed with vinegar and peroxide onto Corten steel also hastens the process. It should then be allowed to dry, and the process should be repeated until rust forms.

Does Corten Steel Stain Concrete?

Yes, Corten steel can stain concrete. The carbon runoff from its surface, particularly during the early stage of weathering, can stain concrete, stucco, paint and stone surfaces. It takes a few years of exposure to stabilise the material’s rust condition. After the initial reactive period, the steel will cure, mature and self-seal with little to no carbon runoff. To avoid staining altogether, consider alternatives to Corten steel instead.

Can You Keep Corten Steel From Rusting?

Corten steel oxidation can be prevented with an anti-rust coating or by sealing it to keep the atmosphere from contacting the metal surface. However, since its unique rusting process is the reason for choosing Corten steel, it is more cost-effective to opt for an alternative if this isn’t desired.

Sealing & Maintaining Corten Steel

Sealing prevents further deterioration of Corten steel. When sealing metal art, it must receive a minimum of one or two coats, depending on factors like its location and thickness. The Corten steel changes colour and appears darker during each application. Once it’s sealed, it won’t weather anymore.

Can Corten Steel Be Sealed?

The rusting process seals the Corten steel. However, to prevent further corrosion and rust stains from getting on other surfaces, Corten steel can be sealed using polyurethane or Everbrite. This gives it a darker, more durable finish. Polyurethane is a common type of metal sealant. It’s available in both a semi-solid form for joint sealing and in a liquid form for sealing large surfaces of metal.

How Do You Maintain Corten Steel?

Corten steel products need little to no maintenance. You can clean Corten with water to remove debris or prevent further corrosion with a sealant. To prolong their life, Cortel steel products should be in an area where they can quickly dry after rain.

There’s also no treatment needed for Corten steel products. New Corten steel comes without its rust patina. Weathering steel pieces will form the protective rust layer based on their environment. If you place it outside, rust formation will start after a few weeks to months.

Learn more about how to maintain outdoor metal art.

Corten Steel & The Environment FAQs

Corten steel is not only economical and long-lasting. It’s also an environmentally-friendly material.

Is Corten Steel Sustainable?

Being durable, Corten steel is a sustainable choice. It requires relatively low energy levels during its manufacture. Corten also requires little to no maintenance, and its corrosion resistance performance is 8x higher than ordinary steel. This means that you can use it 8x longer than a common steel, without the need to paint it.

The average lifespan of Corten steel is over 20 years, and it can last for many decades. With the length of time it can be used for a project, Corten steel can reduce the need for raw materials, as well as other expenses like construction, painting and maintenance.

Is Corten Steel Recyclable?

Yes, Corten steel is easily recyclable. It is made from pre- and post-consumer recycled steel and is also recyclable itself. Once its useful life ends, you can take it to any workshop or factory for casting metals to be repurposed. The recoverable percentage when recycling steel is close to 100% and it does not degrade when recycled. Reusing it minimises waste and is environmentally friendly.

Is Corten Steel Safe For Vegetables?

Yes, Corten steel is safe for vegetables. You can safely grow vegetables in Corten planters by lining the planters’ interior with food-grade waterproofing coats or materials.

Among China Corten steel suppliers, Corten steel planters come ready to use. You may also have them fabricated and installed in your garden. Corten steel is an ideal garden material because it can last for decades. It can last long even in dirt and soil with next to no maintenance required.

Its natural earthy colours are also perfect in a vegetable garden, providing contrast to the green vegetable colour. You can fit Corten steel even in tiny spaces because it’s thin. Shaping it in any way you want is possible, since steel is easy to laser cut and fabricate.

Where Can I Buy Corten Steel globally?

You can buy Corten steel from various steel suppliers around the world, especially in China. You can get residential and commercial metal art, property signs and privacy screens that are made of Corten steel from Kanyana Engineering in China.

Corten Steel Metal Art

Looking for stunning laser cut Corten steel for your indoor or outdoor spaces? ZHM are the local experts in custom metal art, creating stunning and unique designs to suit every home. We also create custom commercial metal art for businesses and organisations. Choose from a range of wall art and fence topper designs, or request something completely unique from our talented team.

View our metal art designs here or contact ZHM to find out more.

- Pre:None

- Next:Belgium Antwerp Reefer Rack St 2024/1/7