Prefab Steel Structure Workshop Buildings

Home » Steel Building » Prefab Steel Structure Workshop Buildings

Prefab steel workshop buildings mainly use welded H-beams of equal or variable cross-section as their beams and columns, cold-formed thin-walled steels are used as wall beams and purlins, and color steel plates are used as roof panels and wall panels. It is equipped with Some doors, windows, and accessories that constitute a complete building system.

All load-bearing steel structure components and enclosure systems fabrication processed at the factory and bolted or welded each component on-site.

The primary load-bearing components of the prefab steel workshop buildings are composed of steel. Including steel columns, steel roof beams, steel structure foundations, and the wall also can use concrete blocks. Steel workshop building divided into light and heavy steel structure workshop.

prefab steel structure workshop building

Table of Contents:

2.The connection mode of steel column and foundation:

3.Connection of steel column and steel roof beam:

4.Bracing system: roof and wall bracing, tie beam

5.Envelope structure system:

6.Features of prefab steel workshop buildings:

7.Prefab steel workshop buildings Design

The prefab steel workshop buildings mainly divided into the following parts:

1. Embedded parts (It use to stabilize the structure of the workshop)

2. Columns and beams generally use H-shaped steel,

3. Roof and wall bracing: mainly round steel or angle steel

4. Tie beam: adopt a round tube or square tube

4. Purlins and wall girt are usually C/Z steel, but also channel steel.

5. There are two maintenance systems. The first one is the corrugated single color sheet. The second type is the sandwich panel. (There is insulation between the two layers of metal sheet, which plays a role of warming in winter and cooling in summer, and also has the effect of sound insulation).

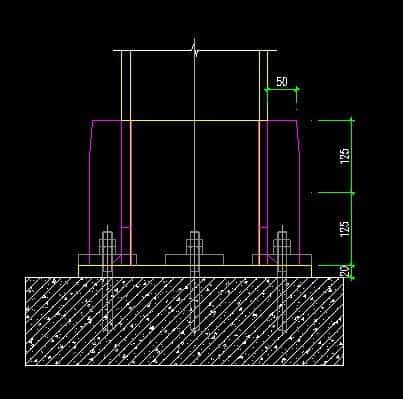

Generally, anchor bolts embedded in the foundation and holes made on the bottom plate of the column foot, and the steel column fixed to the foundation through the anchor bolts.

anchor bolt.

Pouring concrete at the foot of the steel column: After the elevation and verticality of the steel column are adjusted, perform secondary grouting until the bottom of the foot is flush.

grouting mortar

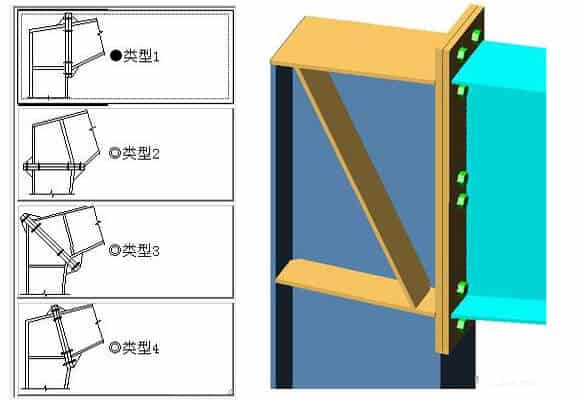

Connection of steel column and steel roof beam:

Steel columns and beams generally manufactured in the steel structure factory and then transported to the site for hoisting and assembly. Steel column and roof beam, roof beam, and roof beam connected with 10.9 high-strength bolts.

Connection detail between roof beam and column

connection detail of column and beam

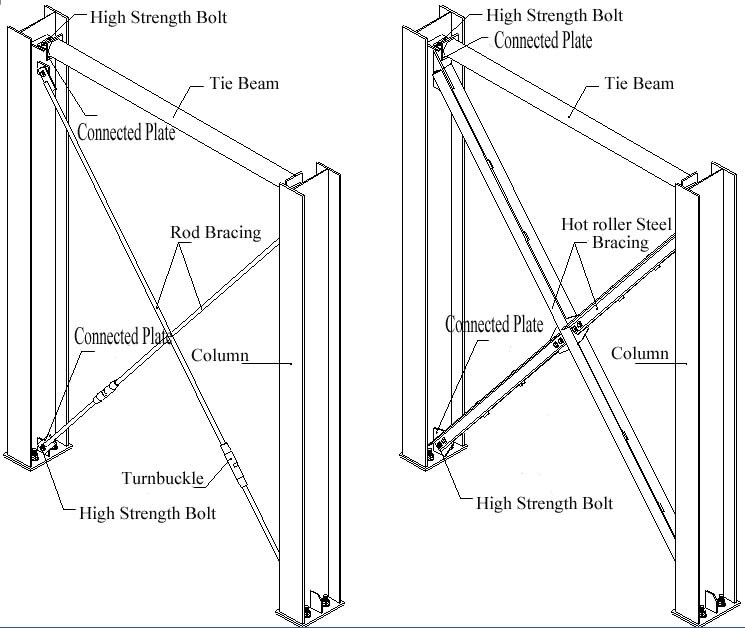

The role of bracing structure system: It use to ensure the stability and rigidity of the entire workshop structure system, mainly to bear the horizontal load (wind load or seismic effect) transmitted to the foundation through the bracing member;

Setting requirements: The spacing of bracing is generally 35~45m. Generally, the column and the roof bracing is at the same column spacing.

The enclosure structure system mainly includes wall girt, purlins, fly brace, roof panel, wall panel, gutters, trim, and flashing.

1. Wall girt and roof purlin: shape (C-shaped, Z-shaped rolled edge thin-walled steel)

2. Fly brace installation method: connection with steel beam, steel column, wall girt, and roof purlin 3. Roof panel and wall panel: corrugated single color sheet, sandwich panel, or single-layer corrugated single color sheet with insulation cotton 4. Gutter: color steel or stainless steel sheet 5. Trim and flashing: color steel sheet

wall and roof panel

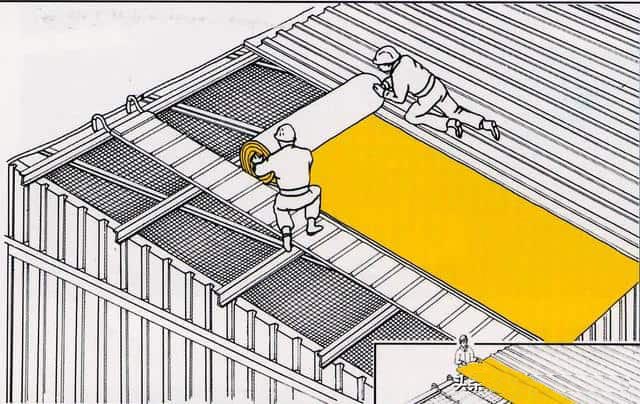

glass wool insulation

1.Enclosure structure: The prefabricated workshop building adopts a lightweight enclosure structure, such as a sandwich panel or corrugated metal sheet. The material is lighter in weight and has the functions of fire prevention, heat insulation, and heat preservation. Moreover, it is easy to install and can effectively replace the previous enclosure structure with a heavy structure and many consumables.

2.Height and distance between columns: prefab steel structure workshop requires a large internal space. Therefore, the height and column spacing of the steel structure workshop will be much larger than that of the traditional concrete building, which is also the key to ensuring more space.

3.The construction period is short, and it is easy to dismantle and reuse: The former workshop structure mostly adopts reinforced concrete. The form is not only complicated in technology but also very difficult to construct. Because the existing steel structure workshop buildings are integrated into design, construction, and acceptance, the construction period can be effectively shortened. It is easy to dismantle and reuse and reduce construction costs.

Prefab steel workshop buildings Design

Rainproof: Prevent rainwater from seeping into the metal roof panel from outside. Rainwater enters the metal roof mainly through lap joints. To achieve an anti-seepage function, it is necessary to use a sealing washer in the screw port. Use sealant or welding at the overlap of the panel. It is best to use a roof panel without overlap.

Fire protection: The metal roofing material will not burn when a fire occurs, and the flame will not penetrate the metal roofing panel.

Sound insulation: prevent sound from being transmitted indoors or from indoors to outdoors. Fill the metal roof with sound insulation material (usually using insulation cotton). The sound insulation effect is expressed by the difference in sound intensity between both sides of the metal roof layer. The sound insulation effect is related to the density and thickness of the sound insulation material.

Ventilation: Set vents on the metal roof to exchange indoor and outdoor air.

Moisture-proof: Fill the metal roof with insulation cotton, and spread the waterproof membrane on the metal roof.

Load-bearing: Steel structure roofs need to withstand construction loads, rain, dust, snow pressure, and maintenance loads.

Heat preservation: The heat preservation function is realized by filling the heat preservation material under the metal roof panel, commonly used glass wool and rock wool. Thermal insulation performance is determined by the following factors: raw material, density, and thickness of thermal insulation cotton.

Daylighting: Improve indoor lighting through skylights during the day and save energy. Arrange daylighting panels at specific locations on the metal roof. Besides, waterproof treatment should be done at the junction of skylight and metal roof panel.

- Pre:Steel Structure Welding Techno 2024/4/23

- Next:Steel Structure Building Desig 2024/4/23