Prefabricated Steel Structure Museum-Yellow River National Museum

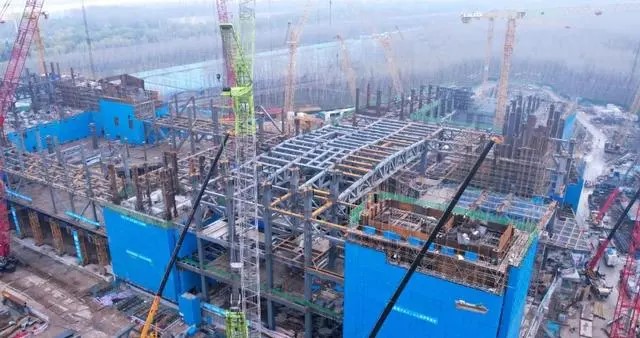

The Yellow River National Museum is under construction at full speed, Our steel structure truss hoisting construction

Recently, the workers of the Yellow River National Museum project, which our company participated in supplying, are carrying out the steel truss hoisting construction. At present, the overall building of the museum has been built to 3 floors, and the "Z"-shaped outline is beginning to appear. The construction site is busy, tense and orderly.

The project is located in the northern suburbs of Zhengzhou. It is a national key project and a key project of Zhengzhou's "14th Five-Year Plan". After completion, it will become a new highland in the Central Plains, a new ecological fashion, and a new historical and cultural landmark of the Yellow River.

The Yellow River National Museum covers an area of about 135 mu, with a total investment of 1.93 billion yuan and a total construction area of about 102,000 square meters, of which the above-ground construction area is about 70,000 square meters and the building height is about 40 meters. The steel structure installation is currently underway, and the main structure of the project is expected to be completed by the end of this month. Among them, our company undertakes the processing and production of 3950 tons of steel structures. Our company's early delivery and high-quality details have won high praise from the owner.

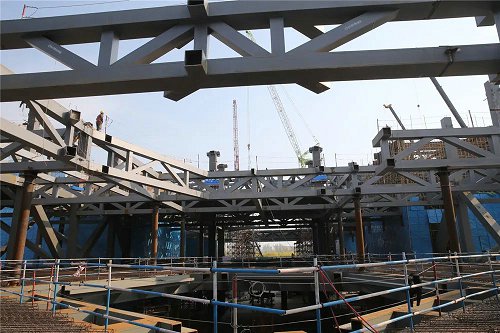

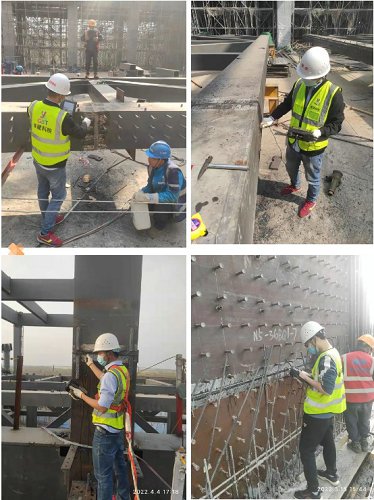

The main project of the museum includes steel trusses with a span of 69 meters and a two-story height, a maximum cantilever length of 24 meters and a floor span of 45 meters, as well as important structural components such as box-shaped steel beams. The amount of steel used is as high as 32,000 tons, which is 3/4 of that of Beijing Bird's Nest. In particular, the steel structures used in the project are mostly special-shaped parts, which are difficult to install and have high technical requirements. It is a severe test for installation and welding workers. In order to ensure the orderly installation of the steel structure, the project department also established a 5G command center, built a smart construction site, and carried out digital simulation construction throughout the process to maximize the quality of the project.

Prefabricated Steel Structure Museum-Yellow River National Museum: 3D Perspective Rendering Picture: Bridge Type Building to presend the tranditional Yellow River, the Mother River of China Nation Resilience.

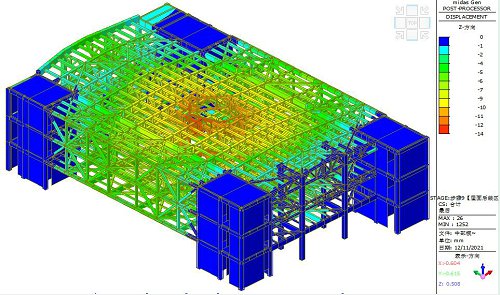

BIM Model of Prefabricated Steel Structure Museum-Yellow River National Museum

South-North length approximate 260meters, East-west width approximate 510meters

Including two floor corridor structures at span 69m.

Maximum cantilever suspended 24m

Floor span 45m steel structure.

Box-type built-up beam girder.

Overall steel structure consumption 56000ton.

With too many pieces of irregular shaped steel structures.

Difficulty in installation

Digital Modeling of installation

Jig support and large scale scalfolding and formwork system

Remote Stress Censer and warning system applied to ensure the overall safety and deflection tolerance during the whole construction period.

Integrated human being and machiner, to upgrade the building quality.

South-North Double wing Block Wise construction Pace Control

South 1st and 2nd Zone Steel truss Installation completion.

Welding Robat

Basement main steel structure completion

Middle zone steel structure mainbody capping roof top

Steel Structure Initial installation

Site Non destructive testing NDT inspection (Ultrosonic Ultrasonic Test) and acceptance by third party inspection authority nominated by local government(Owner).

- Pre:None

- Next:Prefabricated Steel Structure 2024/3/29