Zhonghai Center Twin Tower Office Plaza High Rise Building Steel Structures Zhenru Community Project

Zhonghai Center Twin Tower Office Plaza High Rise Building Steel Structures Zhenru Community Project

Summary of the experience of the above-ground steel structure project undertaken by our company in the Zhenru community project in Putuo District, Shanghai

Steel structure overview

The steel structure of this project mainly includes the T1 tower, the T2 tower and the steel structure in the podium. Total building area 97441m2, including 71691m2 above ground and 25750m2 under ground. This project including one office plaza building, two residential apartment building, one economic building, one Zhonghai Grand Theater, office building 15floors of composited inforced steel column core concrete column-steel beam and RCC core structure.

The Grand Theaterbuilding, with 1 floor under ground, 4 floor above ground, total 5 floors, the main structure type is reinforced concrete frame and shear wall, lobby hall space uses steel truss structure, roof partially are steel frame structure, with maximum piece of giant truss at 140ton per piece and the front hall.

Figure: Schematic diagram of the steel structure layout of this project

The T1 tower has 47 floors above ground. The steel structure is mainly the outer frame steel structure and the rigid steel column of the core tube. The materials are mainly: Q235B, Q345GJB, Q355B, HRB400, etc.

The T2 tower has 39 floors above ground. The steel structure is mainly the outer frame steel structure and the rigid steel column of the core tube. The materials are mainly: Q235B, Q345GJB, Q355B, HRB400, etc.

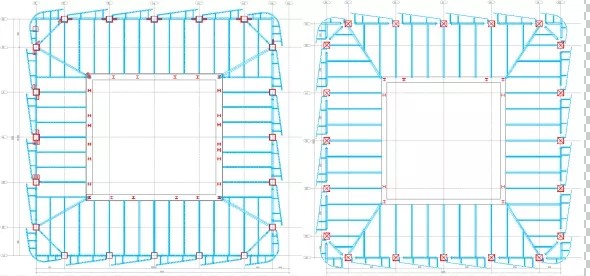

Figure: T1 (left) T2 (right) tower steel structure plan layout

Construction ideas

For the reserved primer part and the primer damaged during transportation and installation, the thickness of the primer should be supplemented by manual or electric grinding. Parts that need to be repainted after installation of components: joint parts, exposed parts, and fastening parts, such as: unpainted parts of high-strength bolts: construction site welding area; the parts of the factory paint that have fallen off after collision are coated with an anti-rust primer. After all steel structures are installed, welded and painted with anti-corrosion paint, the construction of fire retardant paint can be carried out. Spraying should be carried out by area and type. During spraying, aerial work equipment such as aerial vehicles should be used. Safety protection and safety measures should be taken at the construction location of personnel. The materials and finished products of other units need to be protected in advance to prevent pollution; the overall quality inspection shall be carried out after the construction of the fireproof coating is completed.

Office product renderings: (for reference only)

Construction preparation

1) Climatic conditions: Epoxy zinc-rich primer, epoxy micaceous iron intermediate paint non-intumescent or intumescent steel structure fireproof coating can only be carried out in climatic conditions between 5℃-35℃ and relative humidity below 85% . Because epoxy paints are slow to cure below 10°C and stop curing below 0°C; steel structure fire retardant coatings are water-based coatings and cannot be applied below the freezing point of 0°C.

2) Surface cleaning: steel structure surface treatment: remove impurities and oil, and remove surface dust

3) The allocation of paint (specifically according to the climatic conditions and the proportion of the factory packaging barrels)

Figure: Design renderings

4) Base surface treatment:

A If the surface of the steel structure is not painted with anti-rust paint or bruised, it shall be rust-proof and oil-stained, and the surface rust-proof grade shall be St3. B After the rust removal on the surface of the steel structure meets the requirements, the first coat of anti-rust paint should generally be applied within 4-6 hours, and the anti-rust paint should be applied according to the anti-corrosion standard. C If the surface of the steel structure has been painted with anti-rust paint, the surface should be cleaned of oil stains and floating ash to achieve cleanliness. D. If the surface of steel structure is painted with anti-rust paint which is unconventional or interface treatment is required according to the special requirements of the project, an interface agent can be painted to make the fire-proof paint and the anti-rust paint on the surface of the steel structure completely compatible to enhance the bonding strength.

Safety construction is the foundation of normal production of enterprises and the eternal theme of construction enterprises. In the whole process of project construction, organize all employees and professional and technical personnel to study relevant national, industry and regional safety laws, regulations and rules. On the above, formulate the management system of the project department, and carry out normal institutionalized and standardized management of the safe construction of the project. It is to enforce the law, abide by the law, and work in accordance with the safety regulations, so that the safety regulations can be turned into behaviors, produce effects, and strengthen the control of safety work while controlling the quality. The workload of this project is large, the site environment is complex, and there are many high-altitude operations, and the safety production problem should be emphasized.

- Pre:None

- Next:Zhonghai Center Twin Tower Off 2024/3/28