Jinjiang Yixi Yuan Building #1 Residential Building Steel Structure Main Frameworks Completion

Project Name: Jinjiang Yixi Yuan Building #1 Residential Building Steel Structure Main Frameworks Completion

Location: Taiyuan,Shangxi

Introduction:

Building philosophy: Green, Wisdom, Creation, Energy-Saving

Being the first prefabricated and pre-assembly type high rise steel structure residential building in Shangxi province, this Jinjiang Yixi Yuan Building #1 Residential Building is comprised by 2 basements and 34 floors above ground, building overall height 99.8m, total building area 10812.73m2, the assembly ratio of overall building is 94%, the valuation grade is Grade AAA. Each column typical height(length) is 9.03m or every 3floor per section of columns.

Unlike traditional concrete cast-in-situ high rise building, the steel structure residential buildings utilize BIM design model, the narrow flange steel beams (hot-rolled H beams or built-up H-beams) , steel columns (steel plate built-up box section columns or H-section columns), anti lateral load steel braces or steel plate shear wall, composite steel deck reinforced bar latticed sheet and ALC panel( Autoclaved Lightweight Concrete) prefabricated external and internal wall panels to assemble them all together at site by bolt/welding connections, PC staircases, module decoration units to achieve a comprehensive positive result of environmental friendly, energy saving, anti-fire, anti-corrosion protection, short period in construction, high performance of thermal insulation, high fortification of anti-seismic performance, this structure type can reduce 80% of building wastage.

The fabrication method difficulty of this project is the CO2 Gas Robot Automatic Welding Machine Operation, Seamless Double Wire Submerged Arc Welding Workmanship, Box-section Column main welding seam one-off Completion/qualified Testing,

Advantage in comparison with traditional reinforced concrete cast-in-situ project:

Energy Saving: Construction period saves 15% of industrial energy; Building Usage period save 25-35% of energy, reduce mortar quantity by 55%, reduce scalfolding and formwork (Model plate) plate by 60%, reduce building wastage by 70%, reduce construction period by 25-30%( Averagely 3 days per floor construction pace in comparison with 5-6 days per floor of traditional RC structure building) .

Main steel structure system installation completion

High sky working photos: Installation of columns/beams

High sky working photos: Installation of columns/beams

High sky working photos: rectification/adjustment of columns/beams

High density of installed columns/beams

splicing butt welding (full penetration) of box-section of columns

Minimum adjustement of levels/dimensions of columns and beams

temporary guide cable installation and fixing.

Site instrumental measurement to ensure the accuracy of levels and dimensions

Steel member lifting and installation by cranes

Building internal steel members at a glance

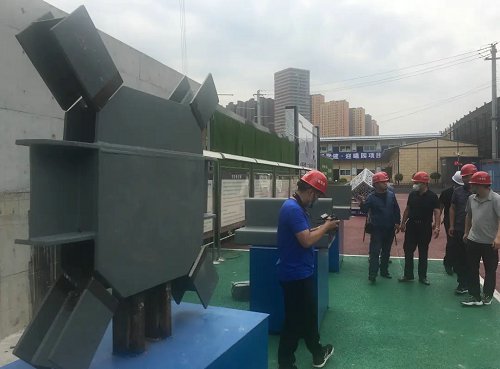

Module and connection samples at the show yard for exhibition

Inspection and visit of client Module and connection samples at the show yard for exhibition

Inspection and visit of client Module and connection samples at the show yard for exhibition

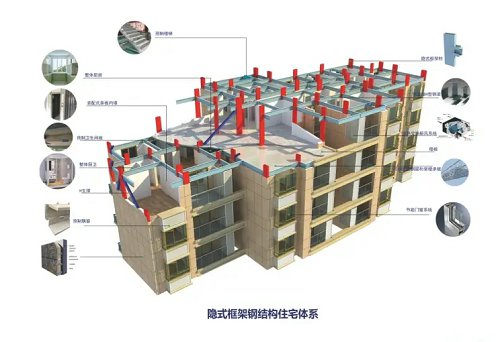

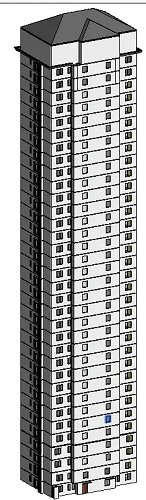

Hidden type steel structure frame residential building system 3D perspective view

Hidden type steel structure frame residential building system 3D perspective view

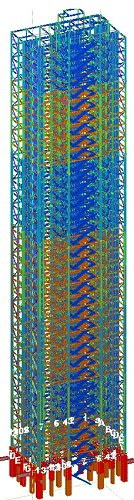

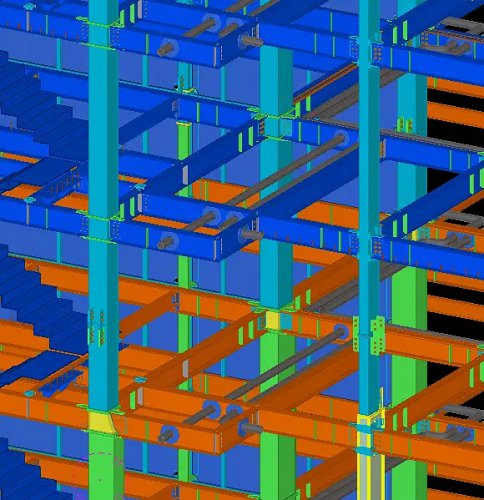

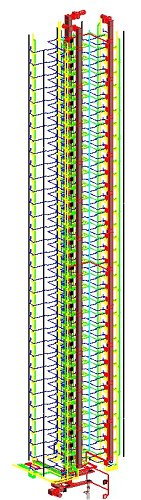

BIM model for steel structure system in Tekla/AutoCAD system

Hidden type steel structure frame residential building system 3D perspective view

BIM model for steel structure system in Tekla/AutoCAD system

Cable/wiring/Plumbing/Sewage Hole Opennings at the steel beams and members

Electrical/Electricity and Machinary System at the steel beams and members in BIM system

BIM system Building Complete sisytem in Revit Model

Steel Structure Under Construction

- Pre:None

- Next:ShaanXi Jinhe New City Sports 2024/2/25