Metal Cladding System

Metal Cladding System

Metal Cladding System

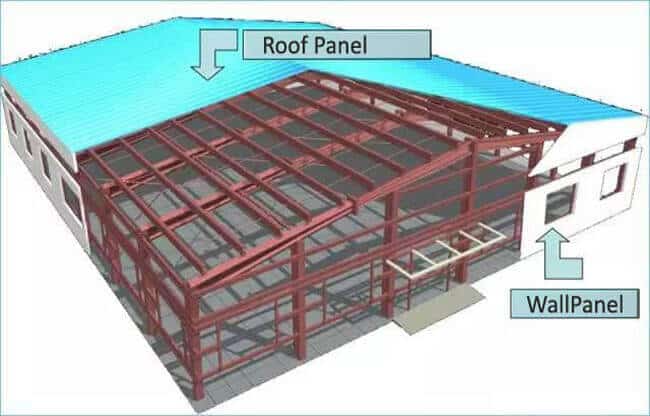

The components of Metal Cladding System

Corrugated Metal Sheet |

Steel Building Insulation |

daylighting panel |

|

Corrugated Metal Sheet Corrugated Metal Sheet is the steel plate with organic coating, which has the advantage of corrosion resistance, beautiful appearance, convenient processing and forming, it has the original strength of the steel plate and lower cost. |

Insulation Insulation cotton is used for coils made for large-area laying. In addition to maintaining the characteristics of heat insulation, it also has excellent shock absorption and sound absorption characteristics. |

Daylighting Panel The daylighting panel can lay from the roof ridge to the eave, parallel to the gable wall, which provides sufficient natural light for the interior, and does not affect the drainage of the metal roof panel. |

|

glass wool sandwich panel |

EPS Sandwich Panel |

PU Sandwich panel |

|

Glass wool sandwich panel Glass wool is an excellent inorganic insulation material. The prominent characteristics of glass wool are excellent fire resistance, high flame retardancy, and moisture absorption, and its price is low. The thermal conductivity of the glass wool sandwich panel is not more than 0.038 W / (m2 • K). |

Polystyrene (EPS) sandwich panel Polystyrene is a material with polystyrene resin as the primary raw material, which is made of foaming agent and has numerous closed micropores inside. The price is low, and the strength is slightly worse. The thermal conductivity is not higher than 0.038W / (m2 • K). |

Polyurethane (PU) sandwich panel Polyurethane sandwich panel has a thermal conductivity of not more than 0.033 W / (m2 • K), has excellent thermal insulation performance, excellent water resistance, high strength, foam can be made into any shape, and is suitable for field construction. |

|

Steel Building Trim |

Wall Panel Installation |

Steel Building Accessories |

|

How to Trim Metal Building The Trim and flashing of the metal building, which mainly uses for waterproofing. Generally refers to the colored metal sheet… |

The installation of Wall Panel The step of wall panel installation, which is applicable to guide the construction process of on-site, the installation of sandwich… |

Steel Building Accessories During the installation process of the wall and roof system, steel building accessories use to ensure the panels fixed to… Read more |

Trim and Flashing for Metal Cladding System

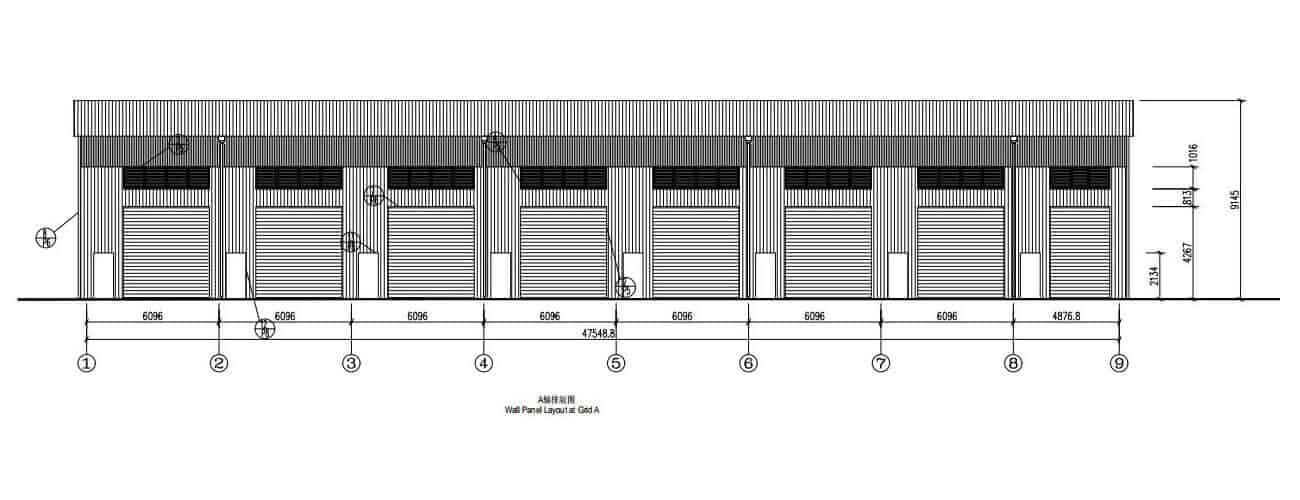

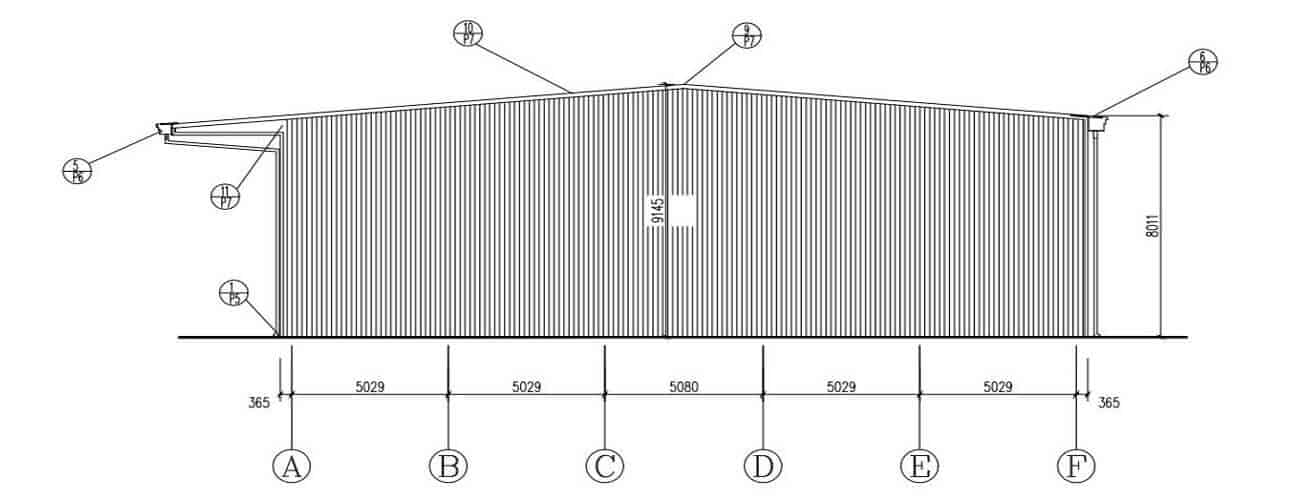

Elevation Plan

Elevation Plan

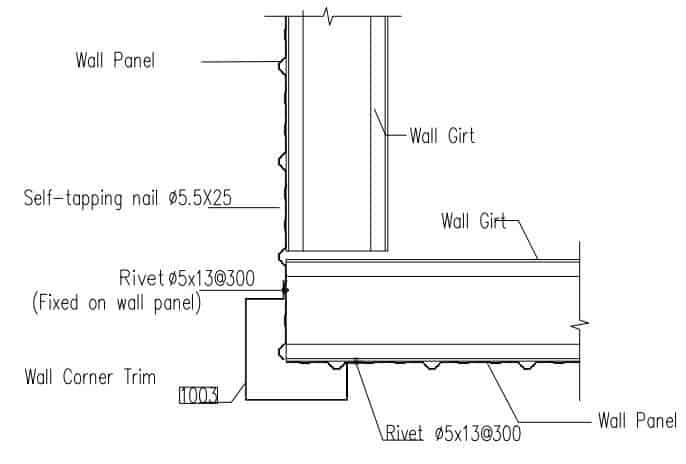

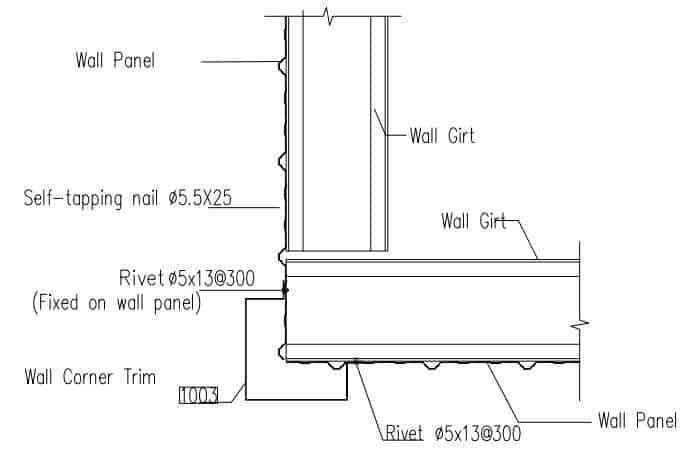

Wall Corner Trim

Wall Corner Trim

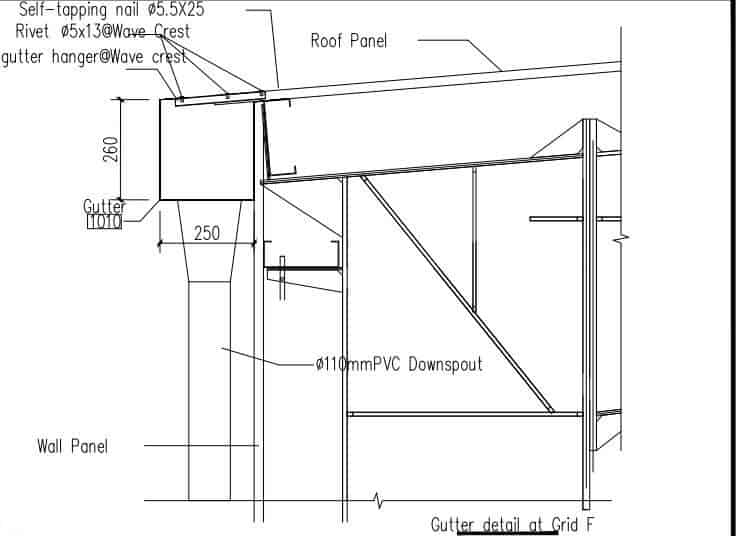

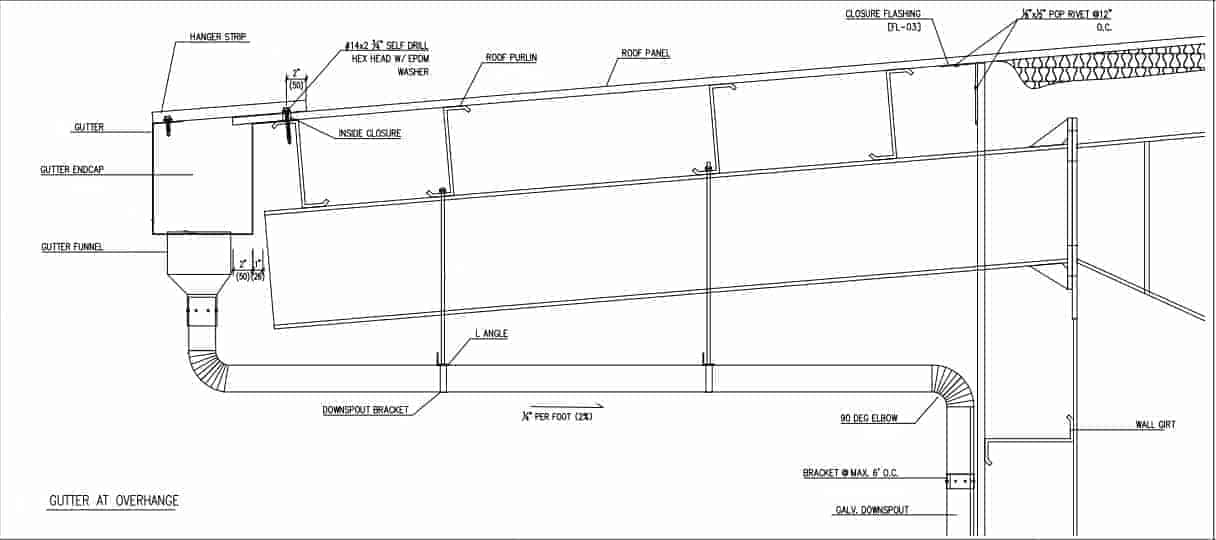

Gutter

Gutter classification:

1. steel plate.

2. galvanized plate.

3. stainless steel.

4. metal color sheet.

Gutter

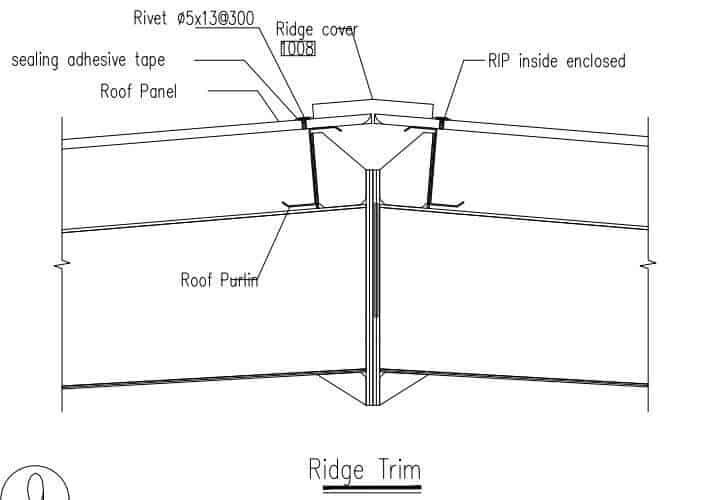

Roof Ridge Cap

The ridge trim cap is erects after the roof panel finishes installing.

Roof Ridge Cap

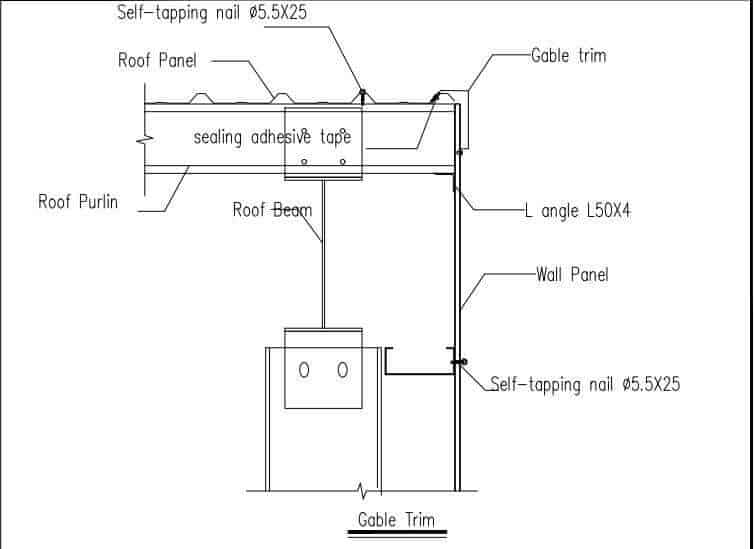

Gable Trim

The combination of the gable trim and sealant provides a waterproof seal for your roof system.

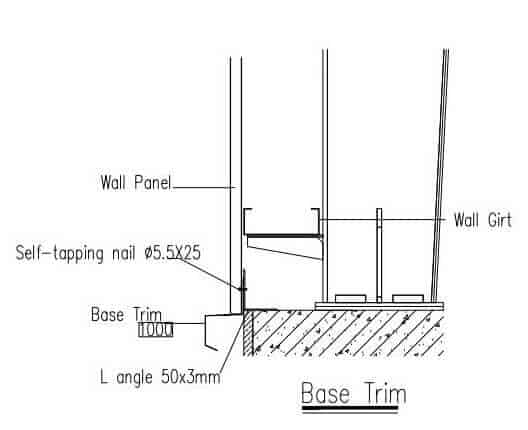

Base Trim

The Base trim uses to prevent the bottom of the wall panel from contacting the concrete slab and protect the metal sheet, and

cover the irregularities of the foundation edges to make the foundation edges more neat and beautiful

Base Trim

Wall Corner Trim

Gutter at Overhang

Gutter classification:

1. steel plate.

2. galvanized plate.

3. stainless steel.

4. metal color sheet.

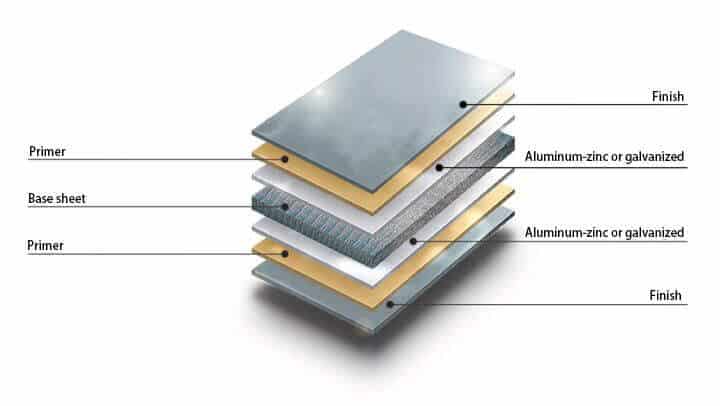

Metal Cladding System-Corrugated Color Metal Sheet

The composition of corrugated color metal sheet:

metal sheet1. Base sheet

The base sheet material ranges from a yield strength of 300Mpa to 550Mpa, and a thickness from 0.3mm to 0.8mm.

2. Aluminum-zinc or galvanized

3. Coating types

1). Types of finish

Polyester (PE)

Silicon modified polyester (SMP)High Weather Resistance Polyester (HDP)

KYNAR@500: Contains 70% polyvinylidene fluoride (PVDF)

2). Types of primer

Epoxy resin (EP, EPoxy resin)

Polyester (PE, PolyEster)

Polyurethane (PU, PolyUrethane)

- Pre:None

- Next:Metal Cladding System 2024/4/21