Open Web Trusses vs. Rigid Frames | Comparison of Steel Structures | ZHM,China Manufacturer Factory Supplier

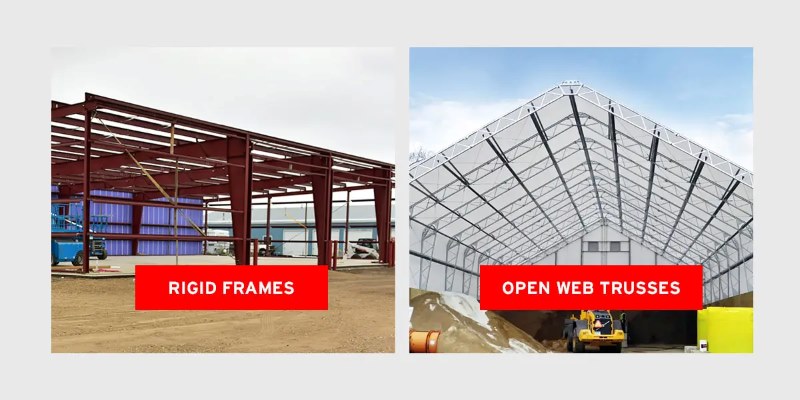

Whether you’re building a warehouse, barn, manufacturing plant, or pre-engineered workshop, there are different structures to depend on. To realize your vision, you must choose between different styles of structural frameworks. Open web truss and rigid frame designs are examples of popular options.

So, when it comes to frames vs. trusses, what’s the better choice? Let’s look at the options.

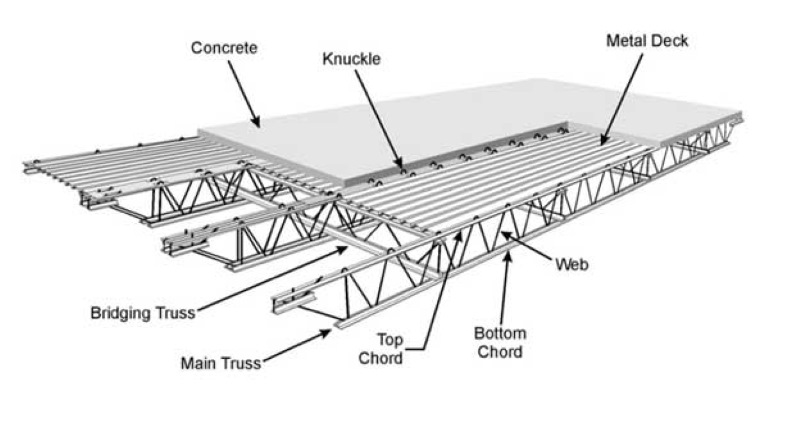

Trusses carry heavy loads, such as the weight of roofs, bridges, and floors. The placement of the diagonal and vertical members allows the structure’s weight to be evenly distributed. Even weight distribution means that open web trusses provide more stable support than traditional roof beams. Additionally, these structures don’t require any extra support beams, so you’ll have an abundance of free-span space beneath the roof for equipment. A further benefit of this type of framing is its ability to prevent wind from lifting the fabric roofing membrane. By keeping the roofing secure, there is less chance of damage to the structure and the equipment inside.

Open truss designs are lightweight because they use fewer materials. However, despite being lightweight, the materials still provide excellent strength and stability for your building needs. A lightweight design also decreases the materials you need when constructing buildings and makes building easier and more manageable.

These frames typically do not require support beams, so they also support a free-span interior, benefitting manufacturing warehouses, agricultural businesses, and other buildings where you need wide-open space, whether to store equipment, park large vehicles, or operate production lines. You will have much usable and open space per square foot.

These durable frames also offer a simple design, making them easy to build and possibly leading to quicker construction. This translates to cost savings.

Differences Between Trusses vs. Frames

Building Size, Type, and Location

Rigid frame structures support a free-span interior, so they make excellent warehouses and manufacturing plants. Their box-like construction also means they support multiple stories.

Because of their versatility, open web trusses are an option anywhere — from agricultural to industrial areas. They make fantastic garages and workshops. Like rigid frame structures, they do not require support beams and are great when you want a wide-open space. Open web trusses also allow for the addition of extra height via custom end walls and sidewalls.

Engineers analyze multiple configurations to determine the best truss components for load-bearing strength, fabrication cost economy, and a pleasing appearance. Open web trusses regularly outperform other truss designs pound-for-pound for carrying and effectively transferring loads.

Both open web trusses and rigid frames are made corrosion- and rust-resistant through hot-dip galvanization — the components get immersed in a bath of molten zinc. The zinc coating helps the steel become corrosion- and rust-resistant, which adds to the longevity and strength of the structure. It’s important to note that the cost per square foot of galvanization is more affordable for open web structures.

Open-web trusses offer an unobstructed view into the frame, allowing for easier wiring, plumbing, and ductwork installation between trusses. Rigid frames are more enclosed, which makes these processes longer and more complicated. The longer processes increase construction costs and require more on-site planning and communication between tradespeople. For example, plumbing tasks must happen at a specific time before or after another project stage, leading to potential disruptions.

Rigid frame installation is more complicated — the connections must be precise for maximum strength and longevity. Plus, you may need specialized equipment for larger structures.

The Summary: Open Web Trusses vs. Rigid Frames

Both of these structures provide impressive strength and support buildings that require wide open spaces, like warehouses and garages. Rigid frames are often used to construct multistory buildings; whereas open web trusses are typically the more affordable of the two because their unique construction allows them to use fewer materials. Both offer weather protection, ensuring high performance in strong winds and snow.

When it comes to installation, open web trusses are typically the better option. The installation process is simple and efficient, which mirrors the process of wiring, plumbing, and ductwork.

When deciding between these two structural frameworks, ask yourself these questions:

- Do you need a multistory building?

- What is the weather like in the area where the building will be?

- Is the plumbing and wiring complex?

- What is my budget?

- Is efficient installation a priority?

- Will the building have multiple floors?

Partner With ZHM Huawu Steel for Your Next Project

Why ZHM Huawu Steel Open Web Trusses vs. Rigid Frames?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Steel Open Web Trusses vs. Rigid Frames ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com

- Pre:None

- Next:Design of Bailey Bridge Load C 2024/8/31