STRUCTURAL FORM, MATERIALS AND DETAILING DESIGN OF REEFER RACK EXPORTED FOR EUROPE

Part 1: Structural Form Arrangement of Reefer Racks Exported for Europe

1.The reefer racks shall be constructed from Hot dipped galvanised structural steel members as per EN/ISO 1461 or ASTM A123, unless approved otherwise

(Supervisor's inspection of our galvanization quality as per EN/ISO 1461 standard)

Part 2: Materials of Reefer Racks Exported for Europe

1.As a minimum, structural steel shall conform to EN 10025 or ASTM A36 or equivalent approved international standard.

2.All steelwork, galvanisation, finishing and coatings shall be compliant with“Structural Steel and Coatings”.

3.Holding down bolts and all structural connections shall use high-strength steel bolts. All bolts, nuts and washers shall be hot dipped galvanised.

4.Floor gratings and stair treads shall be hot dipped galvanised only and shall not be painted. Handrails, stanchions and kick plates shall be galvanised and painted the same colour as the structure frame.

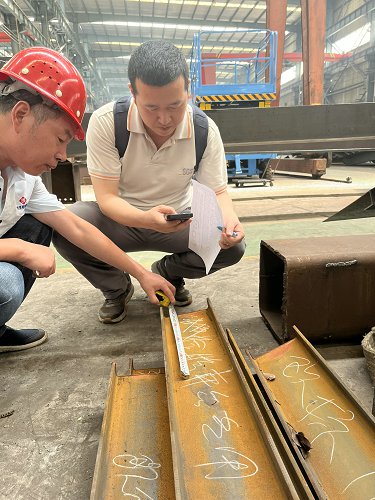

(SGS Supervisor's inspection, sampling for lab testing of our HEB/HEA/IPE raw materials as per EN10025 standard)

Part 3: Fabrication and Erection of Reefer Racks Exported for Europe

1.Welding and drilling at the Site is not permitted.

2.The vertical columns shall be supplied in one piece, unlessed approved by client consultant otherwise for the ocean container transportation purpose.

3.Horizontal members shall be integrated into the floors and bolted in place at the Site.

4.Fixings for all electric parts shall be welded to the structure and drilled before galvanising and painting. Review Point All other parts such as handrails, gratings and kick plates shall be connected by bolts.

(Fabrication of the column and beam frameworks)

(Fabrication of the column and beam frameworks)

(Prepare for packing and container loading of the column and beam frameworks)

Would you like to see more information and images of ZHM’s Metal Structure Reefer Racks ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 or send us your questions via email to info@zhmsteelworks.com

- Pre:None

- Next:STRUCTURAL FORM, MATERIALS AND 2024/5/17