How To Construct A Bailey Bridge Steel Structure In Narrow Site Conditions

How To Construct A Bailey Bridge Steel Structure In Narrow Site Conditions

How To Construct A Bailey Bridge Steel Structure In Narrow Site Conditions

Where is the Bailey Bridge Located?

Temporary Bailey bridges are generally located on rivers, valleys, or emergency roads where temporary passages need to be built. Permanent Bailey bridges are mostly located in downtown areas, parks, and other places that need to cross rivers or ravines. Where the Bailey Bridge is located will directly affect its specific installation method. After knowing how to build a Bailey bridge, we will classify and introduce the Bailey bridge installation under different geographical conditions today.

Bailey Bridge Project Overview

This project is located in the plant area of the Boluo Hydropower Station in Linzhi, Tibet, China. It is designed to connect the factories on both sides of the river. ZHM Huawu Steel engineers designed a double-row double-layer CB200A steel Bailey bridge based on the site conditions. The Bailey bridge length is 54 meters, a single span, the net width of the bridge deck is 4.2m, the total weight is 91.26t, and the design load is automobile-15 class.

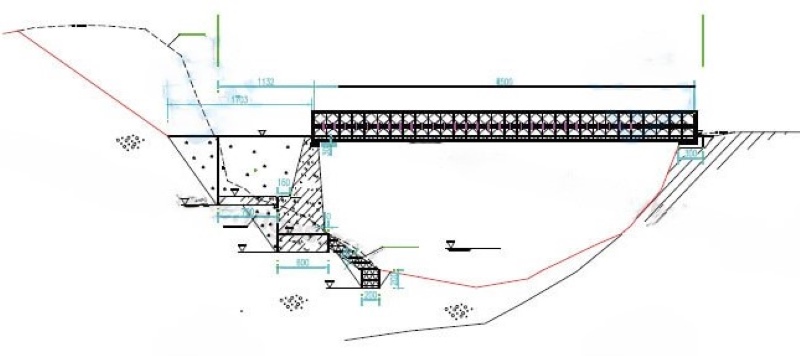

Schematic diagram of Bailey bridge project

Demonstration of Different Bailey Bridge Installation Schemes

Scheme 1: Cantilever push method

The installation method of the Bailey bridge is usually the cantilever push method. This Bailey bridge installation method is the simplest and safest. However, because the Bailey bridge is designed as a double-row double-layer reinforced structure, the installation guide beam used requires at least 15 Bailey frames, that is, a 45-meter-long Bailey frame installation site is required. Limited by the topography of the Bailey bridge location, the narrow terrain on the right bank can only provide a 13-meter-long installation site. Therefore, the installation conditions of the cantilever push-out method are not available, and the program was first rejected by our engineers.

Scheme 2: Erection of wire rope sling installation method

This method requires two wires with a diameter of φ 46m main cable steel wire rope, 20t spreader tonnage required, and it needs to be specially manufactured and processed. In addition, the main cable gantry on both sides of the bank uses a large amount of steel, and the equipment cannot reach the left bank, which will inevitably increase the Bailey bridge cost. This method is difficult and risky and was rejected by the engineering team.

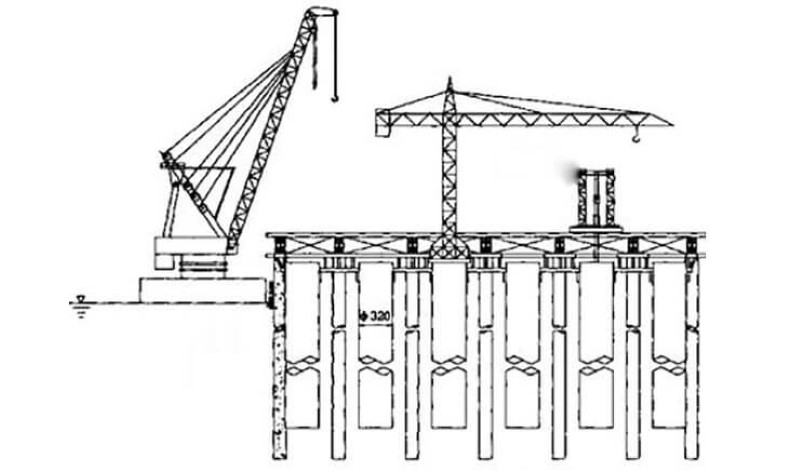

Scheme 3: Large-tonnage crane hoisting method

Large-tonnage crane hoisting method

According to the weight of the Bailey bridge, a large tonnage crane of 120t~160t needs to be used for hoisting. Due to the insufficient load-bearing capacity of several river crossing steel bridges in the process of transporting the crane to the construction site, the crane could not be transported to the hoisting site smoothly. Coupled with the problems of insufficient hoisting sites on the right bank and high hoisting costs, this solution is not suitable for the Bailey bridge installation under this narrow condition.

Scheme 4: Counterweight method

According to the actual installation conditions of the bridge site, and after on-site surveys, ZHM Huawu Steel BRIDGE engineers and project personnel repeatedly demonstrated various schemes, and finally decided to adopt the counterweight method to make the Bailey bridge installation. The counterweight method has low technical difficulty and easy operation. There are Bailey panels on site that can be used for breeding, and the installation process is highly controllable, and the preparatory work is small. Therefore, the counterweight method is the best solution for the installation of the Bailey bridge.

How to Construct a Bailey Bridge Through the Counterweight Method?

The counterweight installation makes full use of the installation site of 13m on the right bank, which is the length of 4 sections of Bailey frame. Install in section 4 each time, and install counterweights in sections 3 and 4. In order to facilitate the installation of the reinforced chords at the bottom and top of the stringer, the position of the counterweight at the 4th section will not affect the connection of the reinforced chords. Install one span and install the corresponding counterweight at a time, and then advance one span forward, that is, advance 3m to the right bank each time. Then install the next section at the 4th section. After the installation is complete, move the counterweight back to between the third and fourth sections, and finally push to the left bank, and so on.

Installation sequence of counterweight method:

- The first step is to install 5 sections of single beams.

- The second step is to install 2 sections of double beams.

- And the third step is to install 5 sections of 4 beams.

Since bulldozers and other mechanical equipment cannot reach the left bank for bridge towing, when the backhoe is used for propulsion on the right bank, the thrust balance cannot be guaranteed or the vibration is too large, which may cause the center of the guide beam to deviate and overturn. Therefore, reverse chain traction is used to advance forward.

The successful erection of the Bailey bridge at the Boluo Hydropower Station provides a good reference for the construction of the Bailey bridge under narrow terrain conditions. This benefited from the rich project experience and technology accumulation of ZHM Huawu Steel engineers and technicians. If you also have Bailey bridge erection requirements, please contact ZHM for consultation.

- Pre:Design of Bailey Bridge Load C 2024/8/31

- Next:How To Build A Bailey Bridge S 2024/8/31