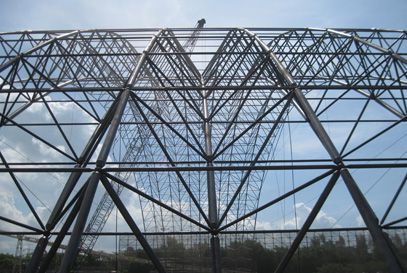

Large Span Space Frame Coal storage shed in thermal power plant and steel plant

large span space frame coal storage

space frame coal storage roof

large span space frame coal storage

space frame coal storage roof

1. The space should meet the requirements of coal storage, with a large span (50m ~ 130m) and a certain clear height.

2. Meet the requirements of mechanized operations; the middle column is not allowed.

3. Continuous production of the power plant, requires continuous maintenance after finishing, high requirements for safety and continuous use.

4. Very high requirements for safety against wind and snow, earthquake, lightning, and fire (prevent structural damage caused by spontaneous combustion of coal), especially against wind damage.

5. After using ten years, prevent the collapse of the structure due to the coal storage in the warehouse and the irregular settlement of the structural foundation (the high safety requirements must be considered).

6. Minimize structural maintenance, power plant is in its own weak acidity or coastal corrosion environment, which is not good for the use of the structure and easy to corrosion. However, the occurrence of corrosion has a great impact on the safety of the structure.

7. Affected by the weather (temperature, humidity, rain and snow), the site as far as possible without welding, construction quality and safety cannot be guaranteed.

Application area:

Coal storage shed in thermal power plant

Coal storage shed of petrochemical thermal power plant

Mine Coal storage shed

Refinery Coal storage shed

Chemical plant Coal storage shed

Steel plant Coal storage shed

Coking plant Coal storage shed

Coal storage shed of heat plant

Paper mill Coal storage shed

1. When the common structure is used for a large span, bad economy, and large components. When the span exceeds 60m, extremely difficult to realize and expensive.

Solution of ZHM: Adopting Multiple statically indeterminate structures, and the span can be more than 130m when there is no column in the middle (usually the span varies according to the wind effect), the structural safety is the highest among all coal yard structures, and the stress is also the best structural form.

2. In a traditional coal yard, columns must be set to affect the use of machinery and occupy the coal storage space. The appearance is not beautiful enough.

Solution of ZHM: there is no pillar in the middle when the span is large, which is conducive to mechanical operation, and ensures maximum coal storage. The appearance can be arc or circular (depending on the mechanical needs), good height, and beautiful appearance.

3. According to the design requirements, the structure is generally guaranteed to last more than 50 years and no replacement of components.

4. Common coal yard is unidirectional bearing type, and weak earthquake resistance, such as wind and snow need to increase components.

Solution of ZHM: Adopting the spatial stress system, the internal force can be automatically adjusted into multiple statically indeterminate structures under the stress state, which is more excellent and reasonable in resisting the natural destructive power.

5. In terms of dealing with irregular subsidence (all subsidence can only be roughly predicted and cannot be completely prevented), it is very easy for a common coal yard to be dangerous, especially under the uneven coal pile pressure within the coal yard, the probability of occurrence is relatively large, causing the coal yard to be scrapped before the design life.

Solution of ZHM: In the design, although the precise calculation cannot be carried out directly, some empirical adjustments can be made, and the structure itself has a strong self-adaptive ability for automatic distribution of internal forces, which is better in the prevention of settlement safety.

6. In terms of anticorrosion treatment, it is difficult for common structures and large components to be galvanized, and site welding of small components will damage the paint coating. The best way to prevent corrosion is to use an aluminum alloy structure (extremely expensive cost).

Solution of ZHM: Zinc plating, zinc spraying, paint, and other treatments can be carried out in the factory, the anti-corrosion effect is good, the overall cost is only 30%~60% of the aluminum alloy structure (note: safety grade, wind, anti-corrosion, power plant location, etc.)

7. Common problems in traditional coal yard installation: generally, large or small components are used for welding and installation on site, which results in high installation costs and long installation time. For example, large components need to occupy large lifting equipment for a long time, such as welding of small components on-site, and there are potential safety hazards.

Solution of ZHM: Miniaturized, factory-made, machined and welded components are all processed in the factory and inspected before leaving the factory. On-site installation only requires the installation of bolts. Short installation period, low cost, installation quality assurance.

8. In recent years, circular ZHM coal yard has become the mainstream of coal yard development in the world.

Process description:

1. Design process:

In general, the load action in the design process of a Coal storage shed mainly includes dead load, live load, earthquake action, wind load, snow load, temperature action, etc. The most influential factors are snow load and wind load. Secondly, there is the important factor of safety consideration, the possibility of settlement and the environmental impact of the wind fields in the area, etc.

Snow load: Coal storage shed structure with a long span, more sensitive to snow load. Wind-induced snow migration exists in the roofs with large spans and large areas should be considered when designing, resulting in uneven distribution of snow load. Therefore, it should be adopted according to the uniform layout of the whole span of snow, the uneven layout, and the uniform distribution of the half span of snow. The snow load and roof live load are not considered at the same time, taking a large value of either.

Wind load: the basic wind pressure and basic snow pressure of the roof structure shall be adopted according to the recurrence period of 50 years; when the space frame structure with a span of more than 120m and the roof structure is complex, the distribution coefficient of wind carrier type, wind vibration coefficient and roof snow (including changes in the process of snow melting) should be appropriately increased compared with the code requirements or confirmed through wind tunnel model test or numerical simulation study. So, wind tunnel experiments will be carried out when necessary to determine the wind carrier coefficient and the wind vibration coefficient.

Forced displacement: the impact of support settlement and horizontal displacement on the structure shall be considered in the design. The uneven settlement of the support shall be considered as 20mm, and the horizontal displacement of the bearing shall be considered as 20mm. But consideration of settlement can lead to significant cost increases.

2. Production process:

(1) the key processing of space frame structure pipe is the welding between blanking plate or cone and pipe, the specification requires weld grade 2, although general grid structure factory is equipped with automatic welding machine, but the Angle of the welding torch, swing speed, and position and speed still need an artificial operation, they will have a great influence on welding quality of steel bar eventually, so the space frame processing factory needs to have a set of mature, proven effective pipe welding technology.

(2)Bolt ball machining belongs to metal machining, the final Angle precision of the screw hole is important to the quality of the bolt ball, and the key to affecting the Angle precision is the precision of the work fixture.

(3)The key to machining the support and bracket is the component’s perpendicularity and weld quality.

3. Installation process:

every new project from the early communication, to the site survey, design, adjustment, construction, lifting scheme (safety, economic), and another whole process of service. The making of the installation plan is closely related to the calculation. At the beginning of the design, it is necessary to calculate the safety of the installation. Otherwise, the safety of the design cannot instead of the safety in the installation. The initial area of the installation must be checked to ensure safety,the installation area should be reinforced if necessary.

ZHM provides two kinds of installation services.

First: to provide supporting construction and installation services to meet the needs of different customers.

Second: the designated technical team provides guidance services, free technical problem solutions, complete installation services, and saves time and effort.

- Pre:None

- Next:Large Span Space Frame Coal st 2024/1/10