The Design of Steel Structure Workshop

Compared with the traditional building model, the factory has more prominent advantages and is favored by many builders and enterprises. So, we need to pay attention to the issues in the design of steel structure workshop buildings.

Table of Contents

1.The attention to the design of steel structure workshop:

1.1.Load-bearing of steel workshop building2.Portal steel frame design:

3.The structural form of the steel structure workshop:

4.Standards for force analysis of portal frames

5.The load effect combination must meet the following standards:

6.Step for steel structure workshop design:

6.1.The Lighting for the design of the steel structure workshop

6.2.Moisture-proof

6.3.Fireproof for the design of steel structure workshop

6.4.Sound insulation

6.5.Thermal Insulation

Load-bearing of steel workshop building

The first thing that needs to be solved in the design of steel structure factory buildings is the load-bearing. The steel structure workshop building must withstand construction, rain, dust, wind, snow, and maintenance loads.

design of steel structure workshop

Portal steel frame design:

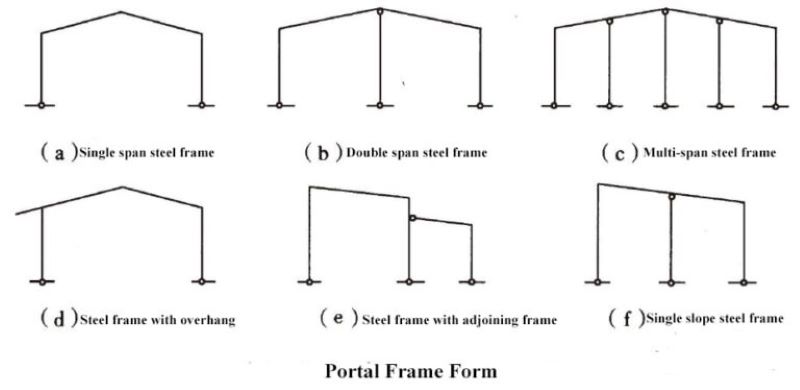

portal steel frame forms

The structural form of the steel structure workshop:

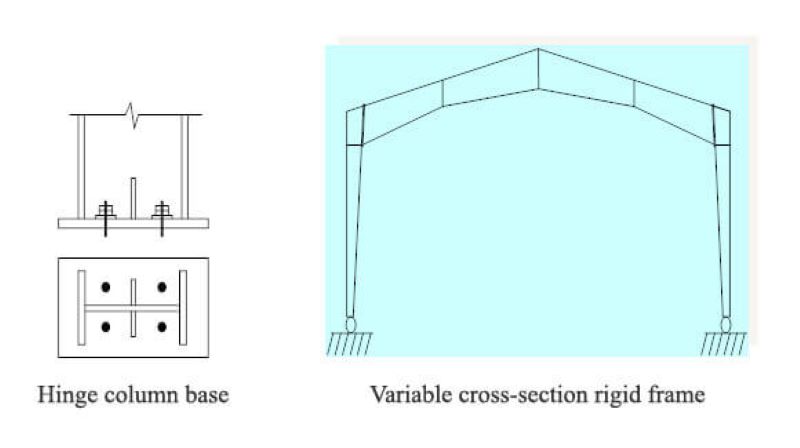

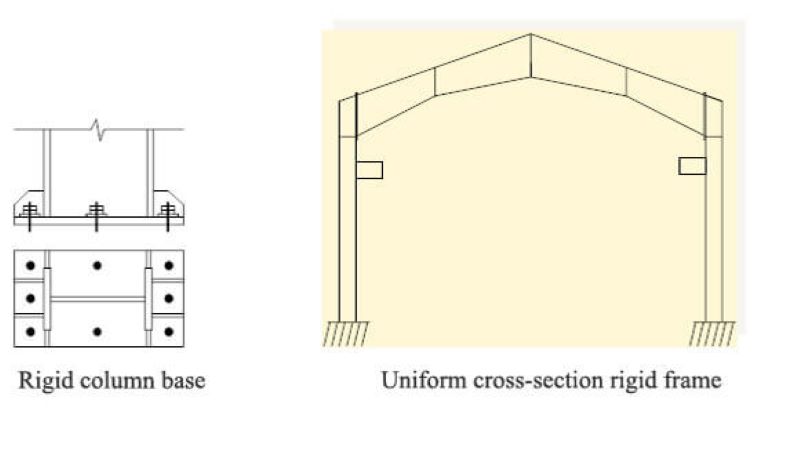

rigid steel frame

steel frame with crane

Since the calculation assumes that the roof live load is fully distributed, the greater the load value, the greater the safety, and of course, the total amount of steel used will also increase accordingly.

The specification points out that if a profiled steel plate lightweight roof is used, the standard for live loads in the vertical direction of the roof should be 0.5kN/m2, including the calculation of roof panels and purlins. However, for steel house structures with a load-bearing horizontal projected area exceeding 60m2 pieces, the horizontal value of the vertical uniformly distributed live load on the roof should be greater than or equal to 0.3kN/m2.

The load effect combination must meet the following standards:

2.The enormous dust load, roof uniform live load, and snow load can be considered at the same time;

3.Construction or maintenance of loads are not considered together with loads other than the self-weight of roof materials and purlins;

4.If multiple cranes are selected, their combination must comply with the provisions of the steel structure design standards;

5.Wind load and earthquake effects cannot be considered simultaneously.

Step for steel structure workshop design:

1.Determine the initial cross-sectional dimensions of the steel structure factory building components, which are generally determined based on the span of the building or can also be determined by the designer.

2.Use design software for mechanical analysis, load combination, strength, and stability verification under various working conditions.3.Based on the actual load effects and various constraint conditions, the total stress section optimization method is used to re-optimize the selection of the cross-section dimensions of each steel structure factory building member.

4.Check the deformation of each point of the beams and columns of the steel structure factory building and meet the requirements of the relevant specifications. If it does not meet the requirements, the cross-section size should be optimized and adjusted according to a certain proportion of parameters concerning the section total stress optimization method until the deformation of all points of the steel structure factory building components is satisfied.

The Lighting for the design of the steel structure workshop

daylighting of steel workshop building

Moisture-proof

Fireproof for the design of steel structure workshop

fireproof of steel structure workshop

Therefore, the steel structure workshop needs to be sprayed with fireproof materials, which can improve the fire resistance of the construction in the event of a fire.

Sound insulation

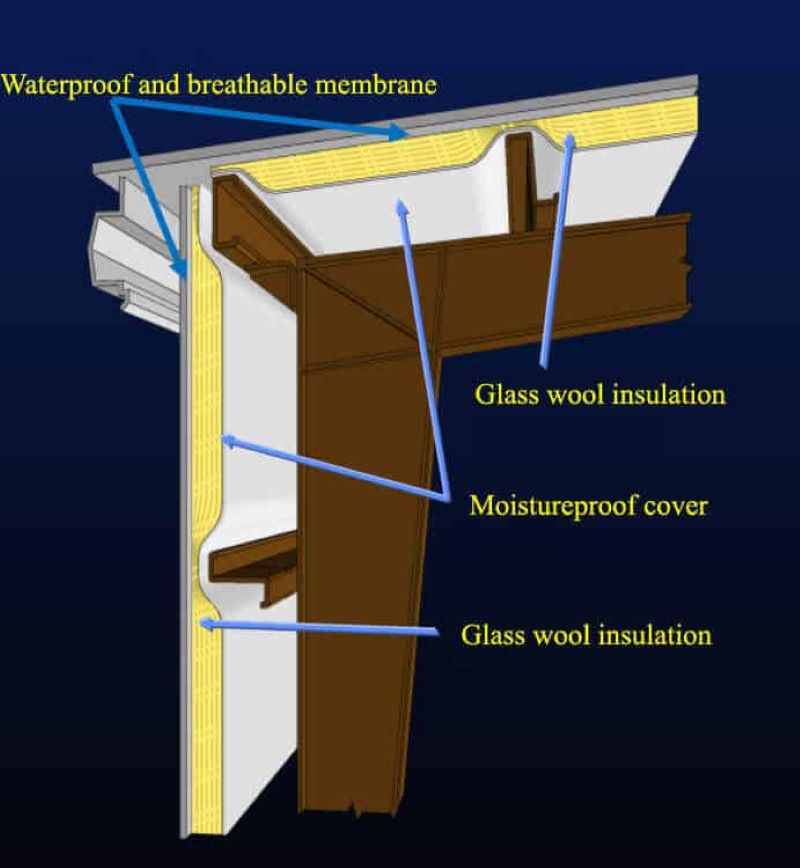

Fill the metal roof layer with sound insulation material (usually made of insulation cotton), and the sound insulation effect is expressed by the difference in good intensity on both sides of the metal roof.

The sound insulation effect is related to the density and thickness of the sound insulation material. It should be noted that sound insulation materials have different blocking effects on the sounds of different frequencies.

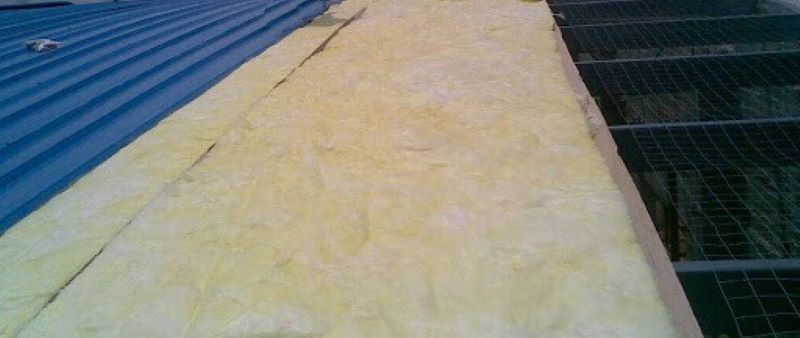

Thermal Insulation

thermal insulation of steel workshop

The thermal insulation performance is determined by the following factors: the raw material, density, and thickness of the thermal insulation cotton. The humidity of the thermal insulation cotton, the connection method of the metal roof panel, and the underlying structure(to prevent the “cold bridge” phenomenon). The ability of the metal roof layer to heat radiation was repeated.

Would you like to see more information and images of ZHM’s The Design of Steel Structure Workshop? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com

- Pre:Steel Structure Systems: Chara 2024/6/22

- Next:Steel Structures Fabrication C 2024/6/19