17-story Office Building Steel Structures | (W)rapper Tower LOS ANGELES, CALIFORNIA

|

PROJECT NAME: (W)rapper |

ADDRESS: Los Angeles, USA |

|

OWNER: Samitaur Constructs |

STRUCTURE TYPE:Reinforced Concrete Frame and steel structure |

|

EPC: Matt Construction |

BUILDING CATEGORY: High-rise structural steel |

|

HEIGHT: 73m |

FLOORS:16 |

|

Developer: Samitaur Constructs |

General Contractor:Matt Construction |

|

Steel Usage:1909 t (By ZHM) / 6500ton (Total) |

Floors: 16 floors |

|

Building Height: 73m |

Building Area: 180,000SF(16800m2) |

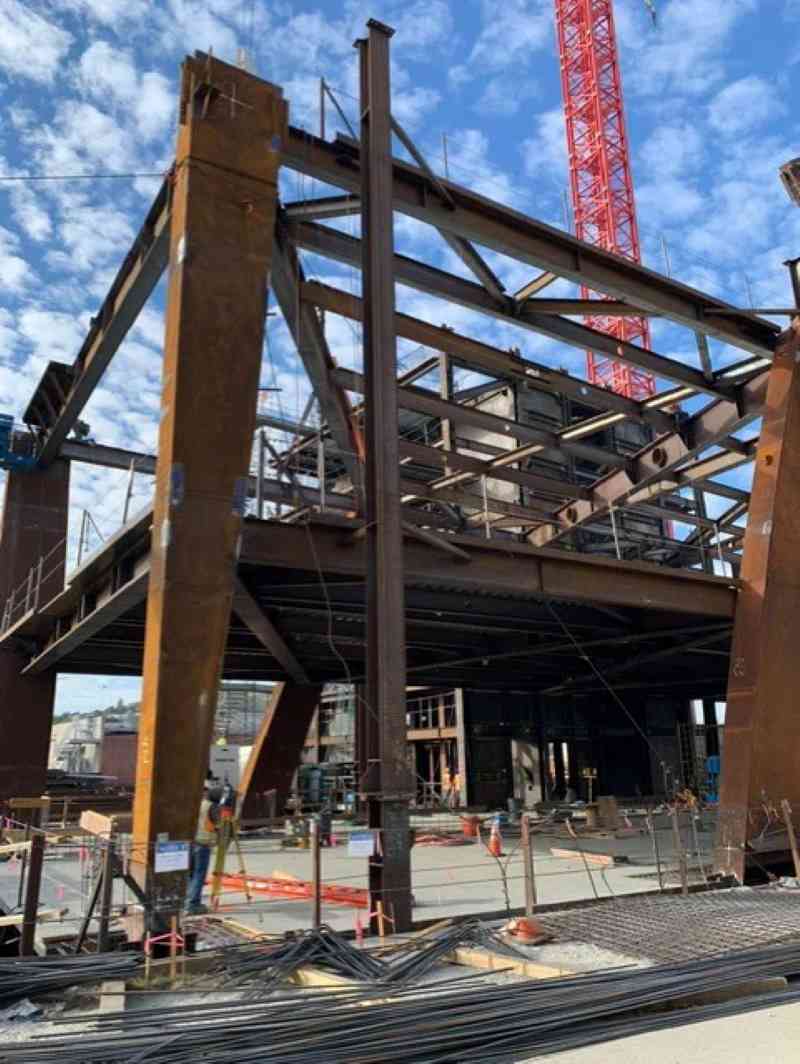

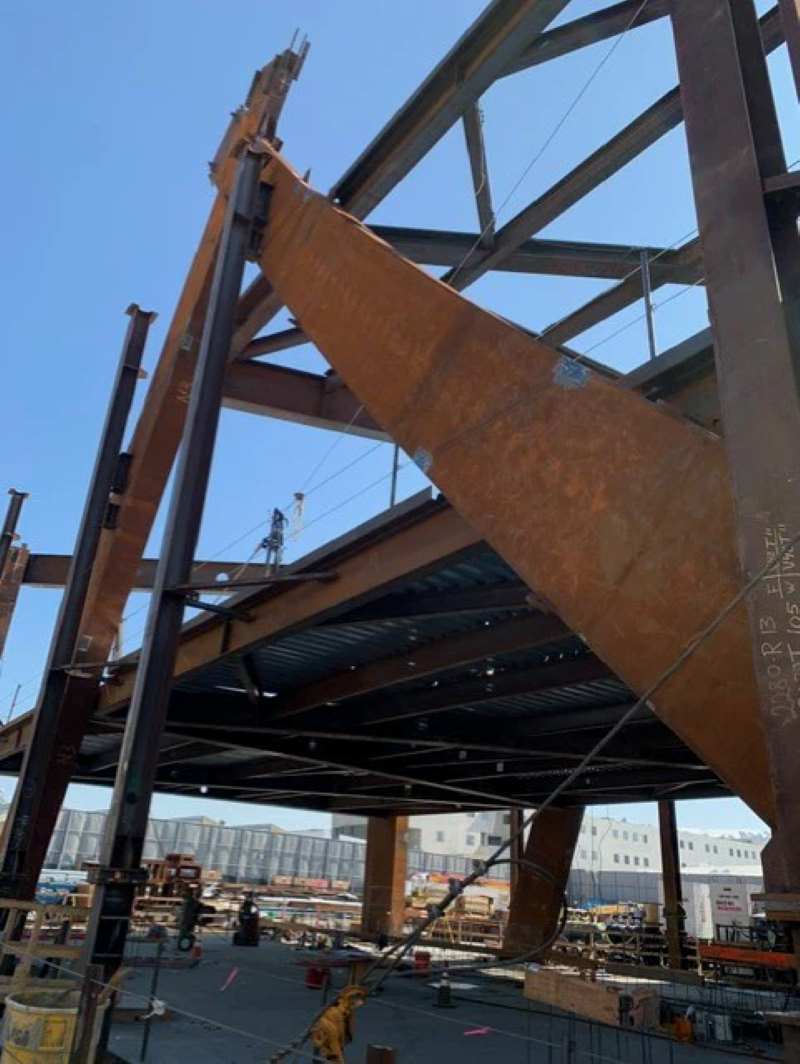

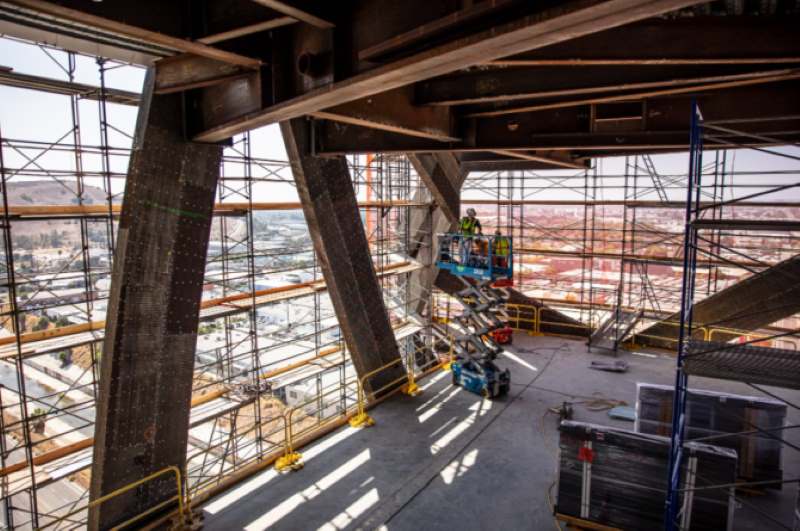

This project is a multi-storey steel structure building. Small in volume but complex in workmanship. The foundation and upper structure are connected by seismic resistance support. The peripheral structure is wrapped with steel bands which known as“Band” structure and working as load-bearing structure.

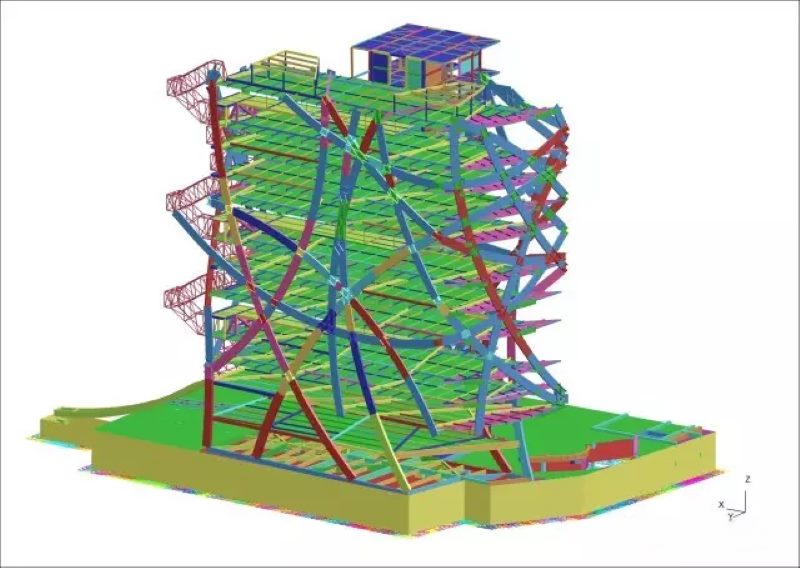

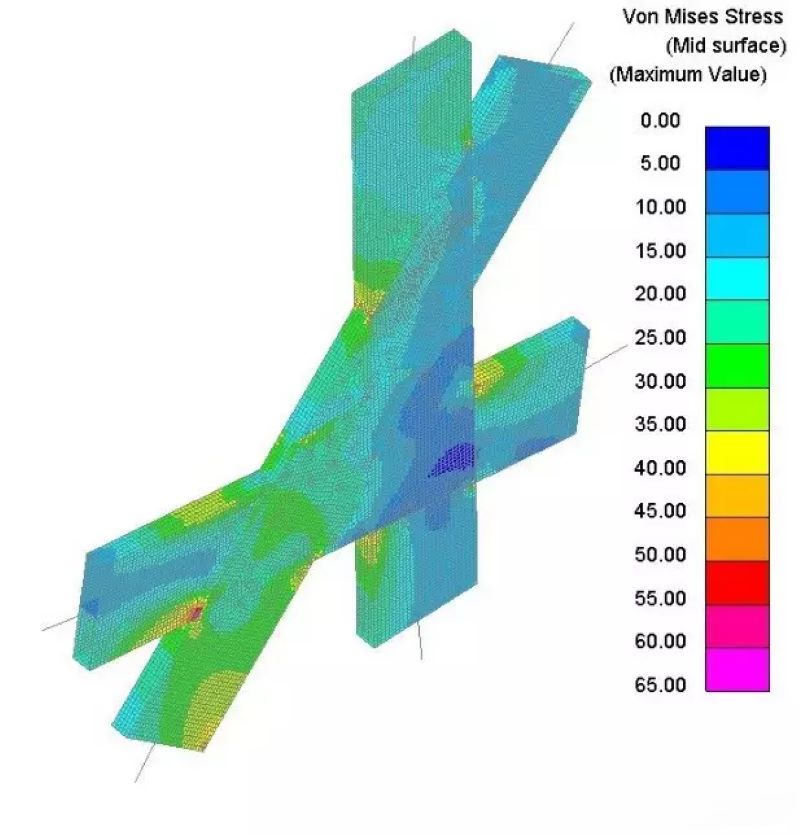

The whole structure is seismic resistance construction (SFRS, seismic force resisting system). The LS-DYNA model non-linear time history analysis was creatively used on this building structural analysis in different data analysis models such as Etabs, Sap, LS-Dyna, Strand7, Visualized software such as web Rhino-Grasshopper, BIM software such as Revit and Tekla. Meanwhile, each software utilitizes their utmost advantages, such as ETABS for floor slab frame design, LS-Dyna for transversal analysis against diffferent seismic grade.

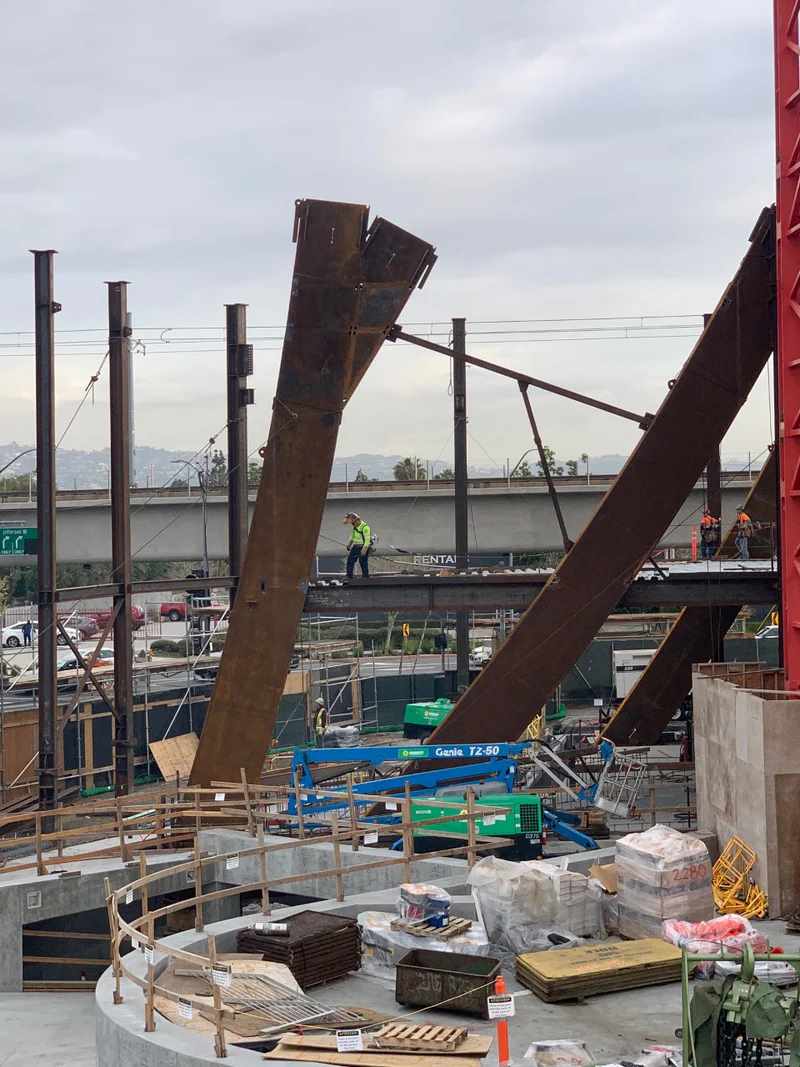

To fabricate and construct the (W)rapper Tower, a 17-story office building with no central columns, the design and construction team is implementing a specialized steel frame exoskeleton around floor-to-ceiling glass windows. This one-of-a-kind commercial space will hold two lower levels of parking and a two-level event deck area for recreation. The seismic base isolation ensures that in the event of an earthquake, the building moves freely. The elevator core is being built conventionally from columns.

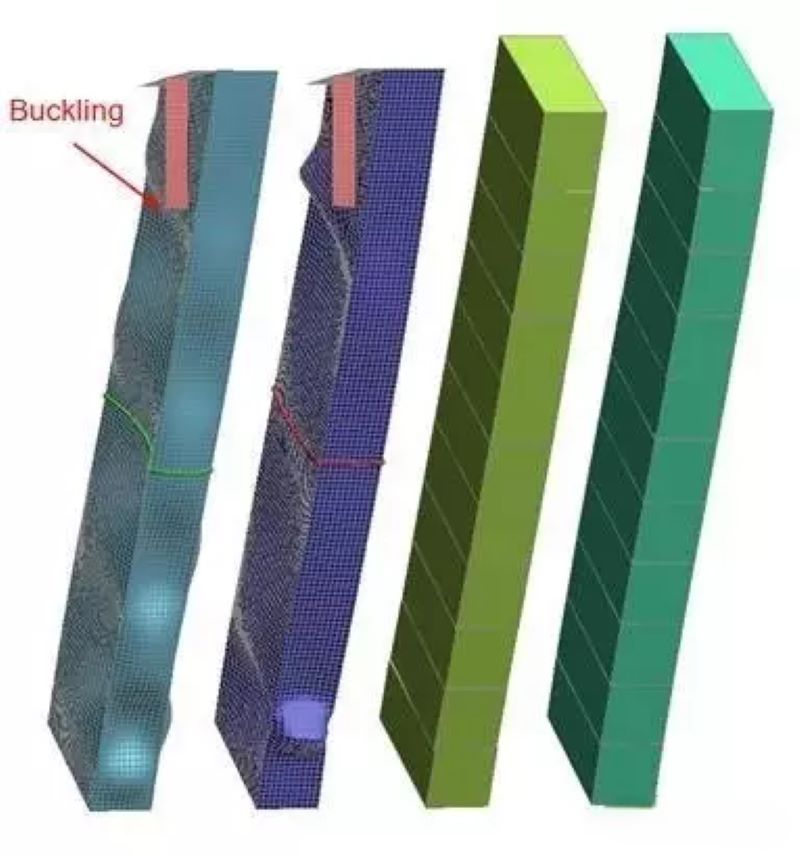

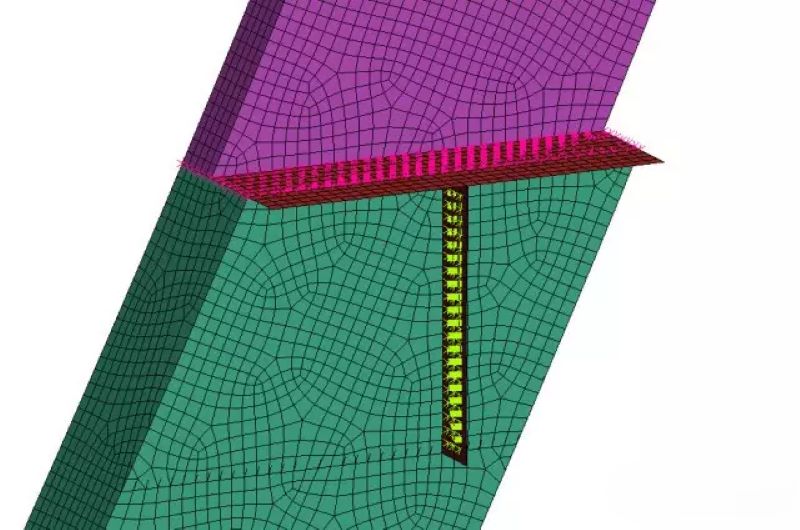

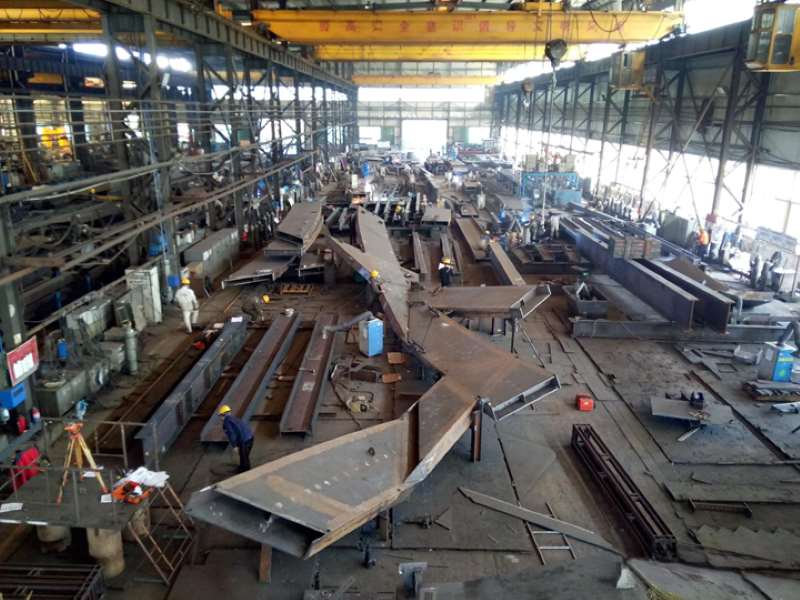

Overseas Business Department Manager Guihua Li told that this project is very difficult and challenging. There is rarely too many fabricators in the world can achieve this production. Most of the structural steelworks are giant curved shape, which requirs very high level of curvation, degree and dimension precision control. All the steel plates used for the columns productions were imported from Germary. Because these plates have very large differences of physical and chemical performance with normal structural plates. We have to do a lot of WPW/WPQRs and Testing and Acceptance procedures for ensuring the welding quality.And make strict control of the pre-welding heating treatment and post-welding insulation treatment.

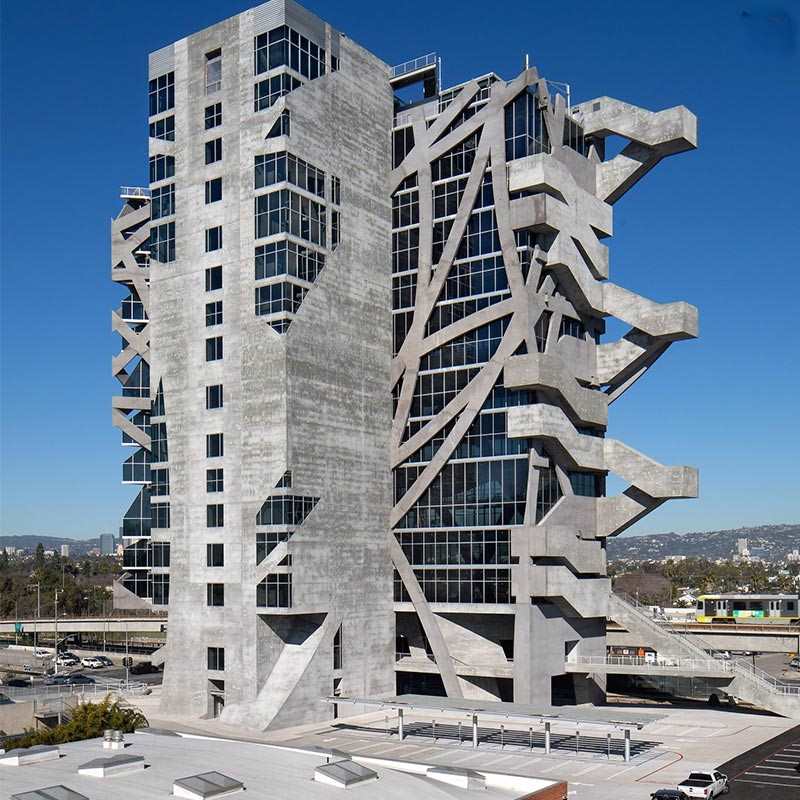

Because the building’s structural elements are located along the exterior, and the elevator core is shifted to the south, massive interior spaces on each floor are almost completely open, with no internal columns or drop ceilings. Add to that a combination of slightly warped walls and wraparound views and one gets the impression of floating in a nest. You can feel the structure around you. The arcing bands frame views in ways you’d never expect, and on lower levels the passage of Expo Line trains lends a dynamic, urban feel that becomes somewhat surreal when you watch the trains curving around the bend, seemingly swallowed by the expanse of the Los Angeles Basin. Floor heights range from 13-and-a-half all the way to 24 feet. All column loads progress down to just three exposed base legs, supported by a base isolator, making the building highly earthquake resistant. (With its VRF HVAC and copious natural light, the building would have achieved a LEED rating if the architects had pursued it.)

When you first look up from the corner of Jefferson and National Boulevards, the gray tower shoots up from its relatively flat surroundings like a launch pad crossed with a gargantuan tree crossed with an ancient ruin. Its mélange of rough, two-coat plaster frontage, tinted and gridded window wall system, and arching structural steel bands (each is a foot thick and five feet tall, coated with spray on cementitious fireproofing), looks somewhat arbitrary. But it’s in fact quite rigorous, growing out of the ever-shifting, arched bands, their loads transferring from band to column to girder and creating increasingly complex building geometries. (3D survey tools were particularly essential for construction.) After some time, it starts to make sense: It’s a building that is entirely driven by its unorthodox exterior structure.

This building, has taken the logic of the beauty of building and express it. Once it comibines architecture and structure, it changes everything.

Why ZHM Huawu Steel multiple-story high rise Office Building Steel Structures ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's multiple-story high rise Office Building Steel Structures ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com