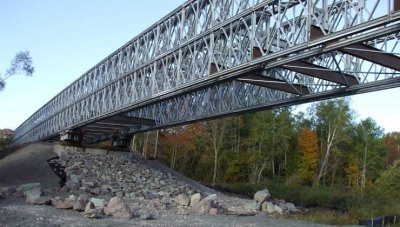

Dependable Modular Steel Bridges Compact 200 Type Bailey Truss Structures

Compact-200 Bailey Bridge is similar to the 321-Type bailey bridge from their appearance. The difference is its increased panel height to 2.134m. For some bridge with longer spans, It employed the method of alternating joints between Reinforcement Chords and the joints between panels. This method can decrease inelastic deformation caused by the oversized pinholes. Pre-arch method is used to additionally cut down mid-span and vertical deflection to a larger degree. Bolt-connected components use the orienting sleeve- fixing method to increase accuracy of connections. Shear is created in orienting sleeves and tension is developed in bolts, which increase the usage life of the bolts and ensure the safety of panel bridges. Wind resistant brace is made to be composite type and is connected to transom/girders to improve overall stability of panel bridges. The part between braced frame and panels is fixed through bridging so as to prevent the whole bridge from side bending. After the erection, there will be a pre-arched degree over the span of the bridge. Besides it can be assembled into single-lane bridges. The compact 200 bailey bridge can also be assembled into double lane bridge, hence it broadens its application range. It is suitable for the load designs of HS-15, HS-20, HS-25 ,HL-93 and pedrail-50 etc.

Content Index

- 1. Overview

- 2.Short Description

- 3.Benefits of C200 Bailey Bridge Modular

- 4.Standard Specification

- 5.Product elements introduction

- 6.Product advantages

The Compact 200 (C200) system is ZHM Huawu Steel’s most widely used modular bridging product and is available for both permanent and temporary applications. With a heritage stretching back over 70 years to the original Bailey Bridge system, the system's extensive use worldwide pays testament to its versatility.

The compact bridge system uses standard, interchangeable steel components to provide robust, rapidly deployed and erected solutions for; permanent bridges, temporary bridges, rural bridges, access bridges, footbridges and emergency and contingency bridging applications. Emergency and contingency bridge stocks, held in country, allow for immediate availability when needed.

The C200 can carry up to two lanes of traffic, with options for internal and external foot walks, and can be configured as a single or multiple span compact bridge. Multi-span solutions are supported on intermediate piers, meaning that there is no limitation to the length the C200 can bridge; this makes it a versatile solution suited to a wide range of applications. Floating bridge solutions, using pontoon systems and bespoke connections, have also been achieved, as well as jetty applications for ferry and barge access.

The C200 can also be adapted to serve as pipe or utility support bridges suited to carrying, for example, oil, water, gas pipes, gallery conveyors and other services and is the most adaptable and versatile solution in the ZHM Huawu Steel range.

For more information on how the C200 suits your application, please speak to our Expert.

| Model Alias: |

C200, HD200,CB200,ZB200 |

| Single lane: | Bridge deck net width: 3.15m |

| Maximum Free Span length: | 60.96m |

| Extra Width Single lane: | Bridge deck net width: 4.2m. |

| Maximum Free Span length: | 60.96m |

| Std. Double lanes: | Bridge deck net width: 7.35m. |

| Maximum Free Span length: | 45.72m |

| Panel Dimension | 3.048m*2.134m(Holes center distance) |

Benefits of C200 Bailey Bridge Modular

|

Modular Rapidly deployed Rapid-build Can be assembled by hand or using light plant Can be crane built or cantilever launched Relocatable Transportable in standard containers Robust Long life with minimal maintenance Multi-span solutions available Optional ramps, footwalks, piers, parapets and barriers Various deck options available |

| Module length | 3.048m |

| Carriageway widths | 3.15m to 7.35m |

| Number of lanes | 1 or 2 |

| Internal pedestrian walkways | 0.5m or 1.0m |

| Cantilever pedestrian walkways | Up to 1.5m |

| Finish |

Hot-dip Galvanised: BS EN ISO 14713 & 1461 ASTM A123 |

Achievable continuous span lengths will vary according to loading. ZHM engineers are able design a solution to suit your particular requirements, taking into account external factors such as site specific topography, low temperatures, high wind loads and seismic requirements. Please contact us ZHM Huawu Steel for more information.

Product elements introduction

The compact-200 Bailey Bridge can be bended and adjust the length, easy to transport.

There is one pinhole on each end of the sway brace, with pin for hanging chains, connecting sway brace and truss by pin. There is a connecting clamp in the middle of sway brace, so as to bend the sway brace for convenience of transport. There is also turn buckle on the sway brace for adjusting the length of brace. In the turn buckle, there is length indicator collet, turning the buckle to brace end in touching with length indicator collet means the brace is in proper length. One end of the turnbuckle, there is locknut, preventing brace from releasing.

Two sway braces are set to the cross of two trusses, assuming the lateral wind-force to the bridge vertically. While installing brace, keep in proper length, tighten the nut, so as to keep the bridge straight and assume wind-force effectively.

1.higher safety

2.single and double lanes are available

3..lightweight components

4..easy disassembly and assembly

5.strong adaptability

6..can be quickly built with simple tools and manpower.

7.wide range of applications

Why ZHM Huawu Metal Dependable Modular Steel Bridges Compact 200 Type Bailey Truss Structures ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Dependable Modular Steel Bridges Compact 200 Type Bailey Truss Structures ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com