Delta Type Steel Truss Modular Bailey Bridges

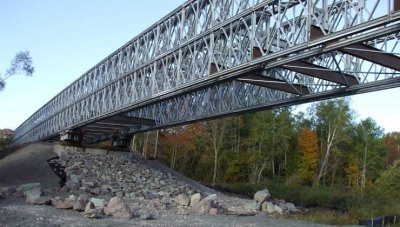

Delta bridge (HZCB450) is a new type of large-span modular steel bridge that can be used to overcome obstacles such as large-span gullies and rivers. Delta bridge is a half-through bridge with a span of 35 to 81 meters in a single span. It can also achieve a multi-span design by adding pier supports, that is, the span length of the Delta bridge can extend infinitely. The deck of the Delta bridge can be made of steel and concrete. Steel decks are mostly used for semi-permanent modular steel bridges, while concrete decks are used for permanent bridges.

Modular Delta Bridge (HZCB450)

Content Index:

- 1.Overview

- 2.Benefits

- 3.Main Technical Parameters of HZCB450 Modular Steel Bridge.

- 4.Standard Specification

- 5.The Structure of Delta Bridge

- 6.Features of Delta Bridge

- 7.The Erection Method of Delta Bridge

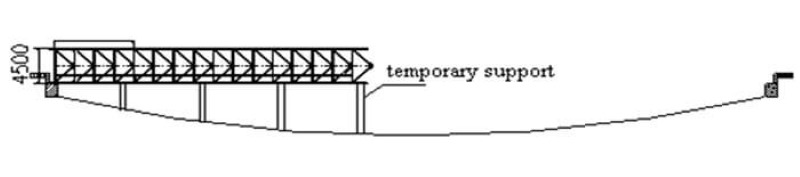

- 7.1.Temporary support method

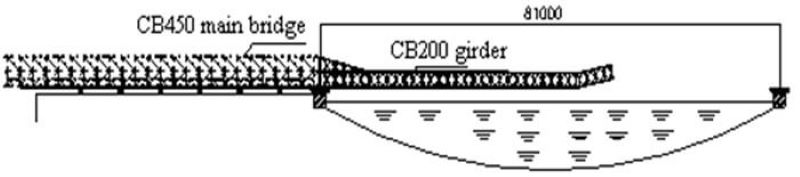

- 7.2.Cantilever propulsion method

ZHM Delta Bridges provide a proprietary pre-fabricated modular bridging system suited for long-spanning permanent applications on main highways or in rural areas. It uses standardised, interchangeable steel components with full highway loading capability to provide a permanent, lightweight, steel bridging solution which can be configured for clear spans of up to 100 metres. It can also be supplied in multiple spans, supported on intermediate piers, meaning that there is no limitation to the length it can bridge.

Combining the best of off-site fabrication with high speed construction and rapid installation, our Delta Bridges offer significant advantages over more traditional construction techniques which involve major site work. The versatility and robustness of its design means that it can be easily assembled and dismantled, making it equally suited to long-term temporary bridge applications.

ZHM Huawu Steel can supply a solution to suit your particular requirements and we are able to accommodate any special load requirements as well as site specific topography, extremes of temperature, high wind loads, and seismic requirements.

For more information on our Delta Bridges and how we can help you, speak to our Expert.

|

Main Technical Parameters of HZCB450 Modular Steel Bridge.

|

Model: |

HZCB450 |

|

Bridge truss height: |

4.5m |

|

Net width of bridge deck: |

single lane 4.2m, double lane 7.35m |

|

Design span: |

span of a single span 36~81m |

|

Deck material: |

Steel deck or concrete deck |

|

Material: |

Q420qc,Q355 |

|

Max. weight of unit component: |

2378 kg |

|

Crane requirement: |

35t; or 10t×10m truck crane |

|

Sidewalk: |

External or internal, support 1m, 1.2m, 1.5m sidewalk |

|

Design load: |

American Bridge Load Standard HS20-44, Chinese Bridge Load Standard Tracked vehicle 60 tons, Highway ClassⅠLoad |

|

Unit weight (steel deck): |

2.63t /m (single lane),3.5t/m (double lane) |

|

Connection type: |

high strength friction grip bolts or high strength bearing bolts |

| Module length | 4.5m |

| Carriageway widths | 4.2m to 10.5m |

| Number of lanes | 1, 2 or 3 |

| Internal pedestrian walkways | 0.5m or 1.0m |

| Cantilever pedestrian walkways | Up to 1.5m |

| Finish |

Hot-dip Galvanised: BS EN ISO 14713 & 1461 ASTM A123 |

Features of Delta Bridge

HZCB450 Modular Steel Bridges |

HZCB450 Modular Steel Bridges |

|

The Erection Method of Delta Bridge

2. Cantilever propulsion method

Why ZHM Huawu Metal Delta Type Steel Truss Modular Bailey Bridges ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Delta Type Steel Truss Modular Bailey Bridges ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com