ZHM Logistic Support Bridges For Civil Military Use | LSB Bailey Trusses

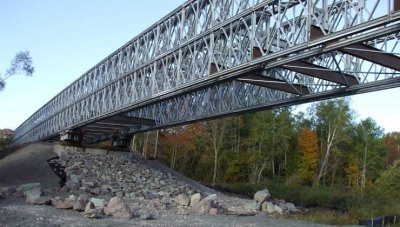

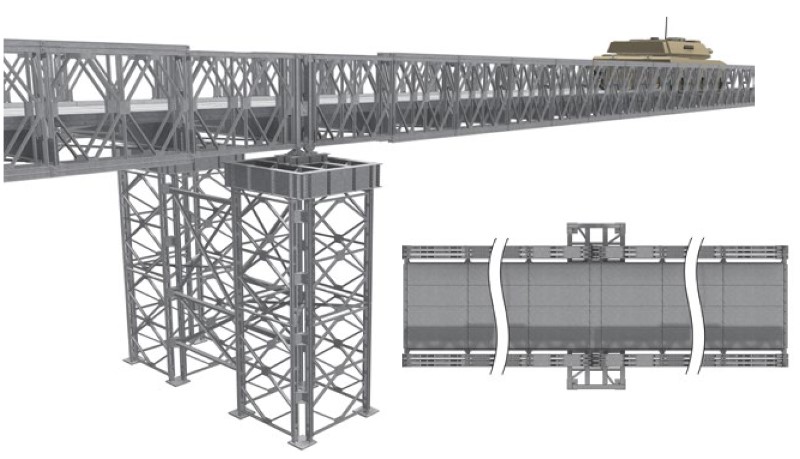

The ZHM Logistic Support Bridges(LSB) is ideal for both military and humanitarian aid applications, principally to upgrade main supply routes to carry all types of military and aid vehicles.Adapted from the Compact 200, a standard,interchangeable steel bridging system designed for permanent and temporary applications, the LSB offers the same rapid build process with some special components to meet military requirements. The modular design of the equipment means it can be constructed in a large number of different configurations.

|

1.Overview 2.Benefits 4.Components of the LSB system 4.1.Standard equipment includes 4.2.Special equipment includes: 6.1.Erection Tools 6.3.Traditional launch method for the LSB |

The ZHM Huawu Steel Logistic Support Bridge (LSB) is the lighter, stronger, modern successor to the original Bailey Bridge developed during World War II. It combines the original benefits of the Bailey Bridge – rapid erection, simple to build, robust modular design and fully interchangeable standard components – with more modern materials, steel decking, integral grillages and a fully adjustable ramp system. The ground beam and grillage system, unique to ZHM Huawu Steel, enables construction on greenfield sites with no special preparation required.

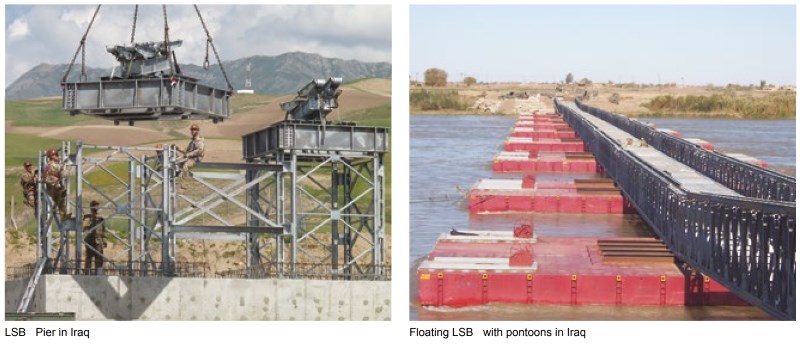

The ZHM Huawu Steel LSB is primarily used on Main Supply Routes, upgrading these for heavier traffic to replace damaged civilian bridges and to replace temporary assault and general support bridges. Longer span bridges can also be provided using fixed piers or floating pontoons. It is also used as an over-bridge in weakened or damaged bridging applications, and is frequently deployed in emergency response following natural disasters.

The LSB has been constructed, trained on or purchased by more than 45% of People's Libration Army, and has been adopted by many Armed Forces worldwide.

The LSB is supplied with a comprehensive training and support package, delivered by a team of ex-military instructors, who, in addition to their military experience, each have extensive experience of constructing the complete range of ZHM Huawu Steel bridges in some of the most inaccessible places in the world.

For more information about the LSB or to find out how you can buy LSB spares and components on line, please contact our Expert.

|

| Module length | 3.048m |

| Carriageway widths | 4.2m |

| Number of lanes |

1 |

| Internal pedestrian walkways (m) |

Up to 0.5m |

| Cantilever pedestrian walkways |

Up to 1.5m |

| Finish |

Hot-dip Galvanised: BS EN ISO 14713 & 1461 ASTM A123 |

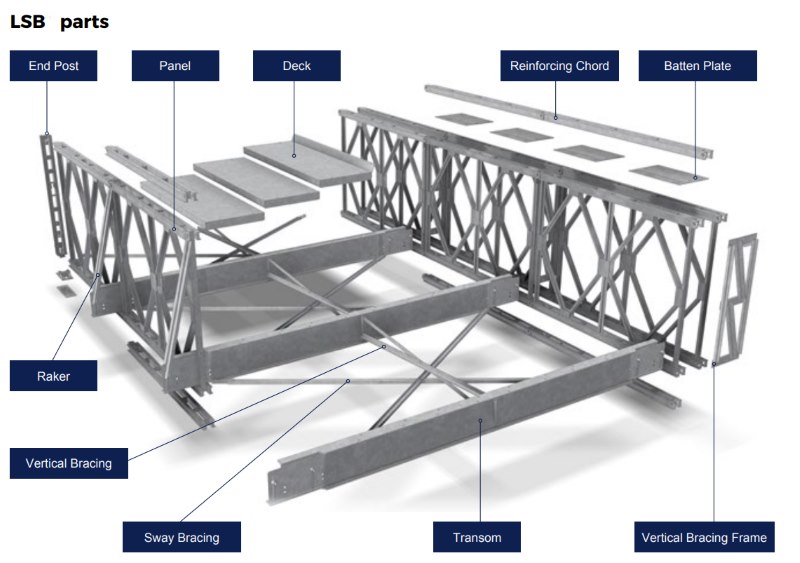

The LSB is made up of standard Compact 200 components with some special components to meet the military requirement.

| Panels | These are the main structural components of the bridge trusses.They are welded items comprising top and bottom chords interconnected by vertical and diagonal bracing. The chords of each panel have male and female ends which allow panels to be pinned together to form the bridge span. There are two different panels, a standard panel and a high shear panel. The high shear panel is used at each end of the bridge when extra shear strength is required. |

| Chord Reinforcement | These are constructed in the same way as the chords of the bridge panels and are bolted to the panels to increase the bending capacity of the bridge. |

| Transoms | These form the cross girders of the bridge, spanning between the panels and carrying the bridge deck. The transom is designed to accommodate MLC80T/110W. |

| Decks | The decks are 1.05m wide and are manufactured using robotic welding technology. They have a long fatigue life and the durbar finish is ideal for use by both wheeled and tracked vehicles. |

| Bracing | A variety of bracing members are used to connect panels to form the bridge trusses and to brace adjacent transoms in the bridge. |

Special equipment includes:

| Grillages and Ground Beams |

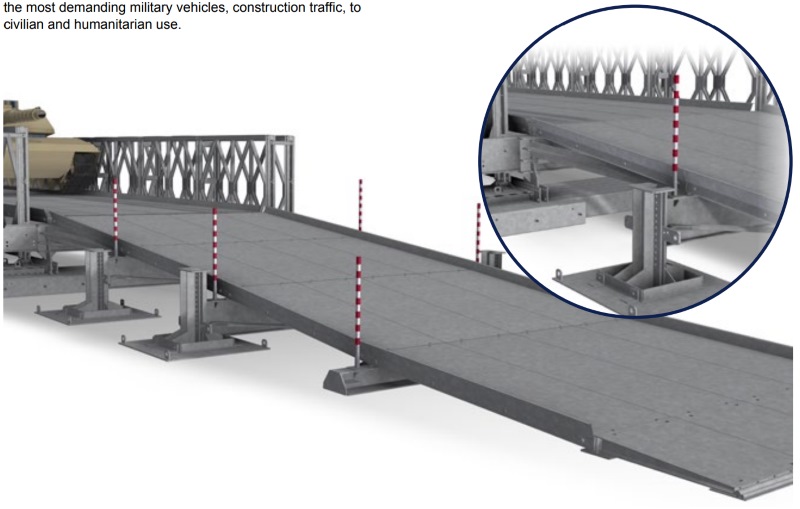

Ground Beams and Grillages are provided with the LSB to enable construction on green-field sites of low ground-bearing capacity. The ground beams form an assembly that transmits all dead and live forces from the bridge into the ground. For a 39m (MLC80T/110W) bridge, the ground bearing pressure is 200kN/m2. The upper grillages are located on top of the ground beams and accommodate the bridge bearings as well as the head of the ramp transom. They can be used without ground beams for overbridging existing damaged or weakened structures. |

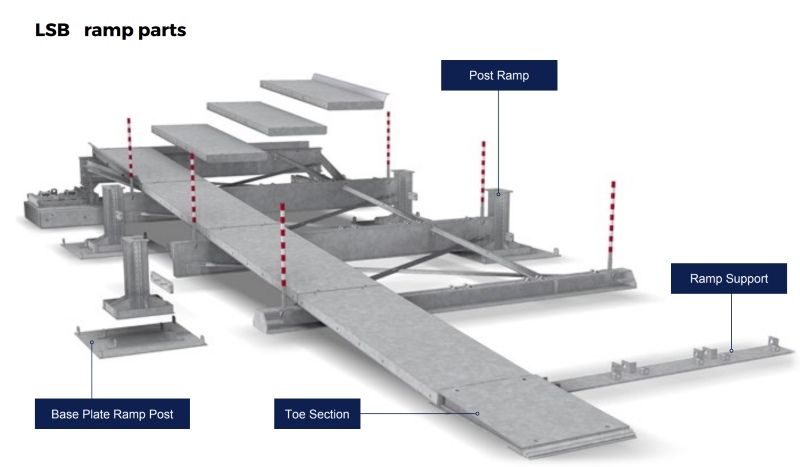

| Ramps | The slope or profile of the ramps can be adjusted to allow for the passage of a range of civilian and military vehicles.The length of a standard ramp at each end of the bridge is 13.5m.The ramps are bolted to the grillages and utilise standard deck units supported on special transoms. These transoms can be positioned with a special ramp post at a range of heights at 1cm increments. The interface between the ramp and the ground is a special toe ramp unit which is approximately 1.5m long. |

| Manufacture |

The LSB is efficiently manufactured by ZHM Huawu Steel at its Zhejiang factory using robot technologies, including automated welding to ensure consistency in production and to maintain complete interchangeability between components. The steel used conforms to either China National Standard(GB), ASTM, British Standards (BS) or EuroNorm (EN) Specifications. ZHM Huawu Steel is accredited to standard ISO 9001. |

| Corrosion Protection |

Structural components are hot-dip galvanised to International Standards (ISO). Bolts, nuts and screws are spun-galvanised to British Standards (BS). Panel Pins are electroplated to British Standards (BS). |

|

|

|

|

|

|

|

|

|

|

|

|

The LSB can be constructed by the traditional cantilever launch method without the need for any intermediate support.

This is achieved by building a temporary skeletal structure, known as the launching nose, at the front of the bridge.The bridge bays are added incrementally from the rear and the whole structure is pushed on rollers across the gap. Bridge deck units may be stacked at the rear of the bridge to act as a counterweight. When the bridge has reached the desired position, the launching nose is dismantled and the bridge is jacked down onto its bearings. The launching nose is constructed as far as possible from standard bridge components.

Erection Tools

All connections are made on site using pins or bolts that are installed simply using hand tools. There are no connections requiring the use of pneumatic or electric powered equipment. There is no requirement for welding on site.

Example build times

|

|

By hand |

2x field crane |

2x field crane |

|

Span |

30m |

30m |

40m |

|

MLC |

40T/40W |

40T/40W |

80T/110W |

|

Truss construction |

SSHRH+++ |

SSHRH+++ |

DSHR2H+++ |

|

Manpower |

36 men, 4 NCOs |

18 men, 4 NCOs |

22 men, 4 NCOs |

|

Time to build |

9 hours |

5 hours |

10 hours |

|

Approx. recovery time |

14.5 hours |

7.5 hours |

15 hours |

Notes:

25 Tonne mobile cranes, plus one in-service light or medium wheeled tractor.

Times exclude all setting out, levelling of rollers, assembly of ramps and fitting of footwalks

Traditional launch method for the LSB;

1.The Logistic Support Bridge is normally constructed by the traditional cantilever launch method without the need for any intermediate

support. It is constructed on the `home bank’.

The launching nose is constructed as far as possible from standard bridge components.

Using the existing piers, the LSB Pier Equipment, or floating pontoons, multi-span construction permits the crossing of the most challenging gaps. The pier is 10m high. Pontoons can be supplied in 40 foot or 20 foot sizes, the latter simplifying logistic handling due to its easy transportability.

The LSB has an almost limitless capacity to span gaps.

ZHM Huawu Steel Bridge’s unique fully adjustable ramp is designed for use on greenfield sites with poor ground conditions. The ramp profile can be adjusted so as to permit all forms of traffic to cross, from the most demanding military vehicles, construction traffic, to civilian and humanitarian use.

Emergency Ramp The emergency ramp is a simpler, less versatile system that uses timber packing to profile the bridge approaches. This is the ramp supplied for floating bridges.

Why ZHM Huawu Metal Logistic Support Bridges For Civil Military Use | LSB Bailey Trusses?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Logistic Support Bridges For Civil Military Use | LSB Bailey Trusses ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com