Organic Rankine Cycle (ORC) and Thermal Oil Heating Plant Steel Buildings | MLTC Bioenergy Centre Power Plant

Organic Rankine Cycle (ORC) and Thermal Oil Heating Plant Steel Buildings | MLTC Bioenergy Centre Power Plant

The MLTC Bioenergy Centre is a combined heat and power, carbon-neutral, energy system consisting of a 6.6 MW (net) power generation system while also providing process heat for kiln-drying NorSask’s lumber. The facility is fueled by residual woody biomass generated by the NorSask sawmill. The carbon-neutral plant is capable of producing 55,000 mw-hrs per year to the SaskPower grid – enough to power 5,000 homes.

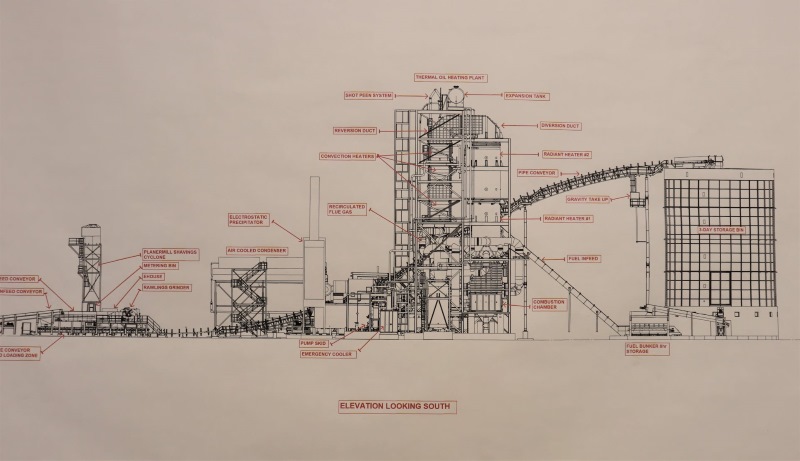

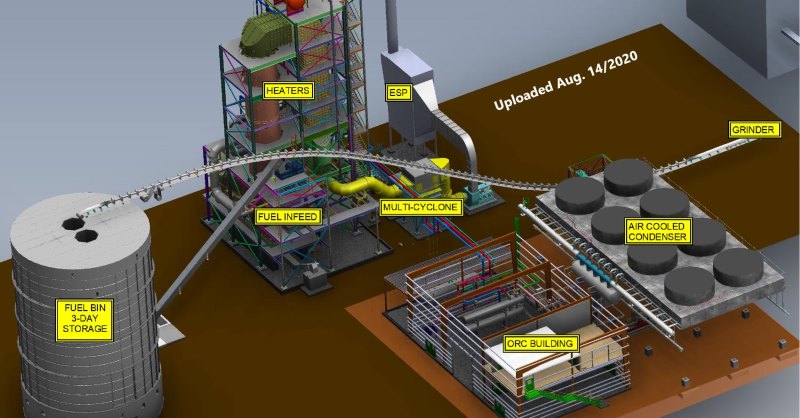

The Design, Engineering, Detailing, Fabrication, Painting, Delivery and Supervision of Installation: Scopes:

- (1)Organic Rankine Cycle (ORC) Steel Buildings with turbo-generators and all associated fuel handling and environmental emission systems

- (2) Thermal oil heating plant mounted Air-cooled, refractory-lined, reciprocating grate furnace with thermal oil radiant heat exchangers

- (3) Exhaust Steam Air Cooled Condenser (ACC) structures

- (4) Wood Pellet Waste Piling Storage Shed Building

- (5) Biomass Wood pellet waste fuel Storage Bin (3-Day Capacity to cover the period of weekend holiday)

- (6) Fuel Infeed/Outlead Pipe Belt Conveyors and their stack tower and transfer towers (including their related staircase towers)

- (7) Electrostatic Precipitator (ESP) Building and facilities

- (8) Planermill Shavings Cyclone Tower equipped with Metering Bin, Ehouse, Rawlings grinder, Feed conveyor, infeed conveyor,etc

- (9) Pump Skid, piping skids, emergency cooler skid;

- (10) Recirculated flue gas ductwork, diversion duct work, thermal insulated Expansion tanks(with shot peen system), combustion chamber houses and casings;

- (11) Gravity take-up transportation system steel works

- (12) Cable trays and frameworks

-

The installation involves one air-cooled, refractory-lined, reciprocating grate furnace with thermal oil heat exchangers, a 6.6 MW Organic Rankine Cycle (ORC) turbo-generator and all associated fuel handling and environmental emission systems. The bioenergy plant achieves significant environmental benefits by reducing the carbon intensity of the SaskPower grid, reducing the use of natural gas for industrial process heating and completely eliminates adverse particulate matter in air emissions. The bioenergy plant enhances the economic outcomes of the nine Indigenous communities associated with the Meadow Lake Tribal Council through improved operations of Canada’s only 100% Indigenous-owned sawmill by converting a waste stream into valuable energy. The ultimate recipients of the ongoing long term benefits of the bioenergy centre are the Indigenous youth and families of the Meadow Lake Tribal Council located in northwest Saskatchewan.

How exactly does the wood waste from NorSask become electricity? First, wood waste from NorSask goes through a grinder from Rawlings Manufacturing, which grinds the wood waste into pieces around three inches by three inches large. This wood waste is then transported by an open-air pipe belt conveyor to the Bioenergy Centre, where the material is dumped into a silo that is approximately 60-feet-wide by 80-feet-tall.

The silo can store up to three days’ worth of fuel, since NorSask does not run on the weekends, but the Bioenergy Centre will run 24/7.

From the silo, the material goes through an auger system and is carried by conveyor to the top of the thermal oil plant, which is a 120-foot-tall building with a reciprocating grate furnace from Classen Apparatebau Wiesloch (CAW) at the bottom. The fibre drops down on top of the furnace, where it is slowly burned. The fire slowly heats tubes in the plant that are filled with thermal oil, similar to radiator heating, Rasmussen says.

From the thermal oil plant, the oil travels to the Organic Rankin Cycle building, which houses an Organic Rankin Cycle power generation system from Turboden. There, the hot thermal oil heats another oil called cyclopentane.

“That cyclopentane, when it gets to a certain temperature, turns gaseous. When it becomes gaseous, then it turns the turbine, which turns the generator that produces the energy,” Rasmussen explains.

The photos of the products ready for shipment in ZHM workshop and at port

The photos of the products of site construction and erections:

Why ZHM Huawu Metal Organic Rankine Cycle (ORC) and Thermal Oil Heating Plant Steel Buildings ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal Organic Rankine Cycle (ORC) and Thermal Oil Heating Plant Steel Buildings ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com