Burn Rooms | Burning Rooms | Calcium-Silicate Tiles | Accessories Of Fire Simulator Training Towers

Burn Rooms | Burning Rooms | Calcium-Silicate Tiles | Accessories Of Fire Simulator Training Towers

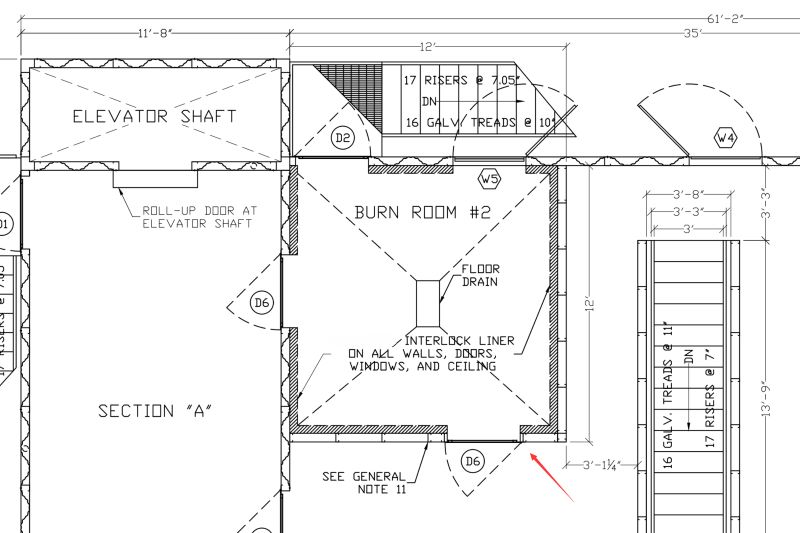

The strongest fire training towers merit the strongest insulating panels. ZHM calcium-silicate-based thermal insulating panels are attached to metal mounting channels. The system is designed to allow for an additional insulating air space between the panels and the walls of the building. Each insulation is custom engineered and arrives on-site with a complete set of plans.

Highly durable, low maintenance insulation

Protects metal, masonry, concrete

Class A or gas simulator fires

New construction, retro-fit, or repair for damaged buildings

Realistic “dry-wall” appearance

Works well with thermal imaging cameras

No “drying out period” between uses

No fire placement restrictions within room

No freeze/thaw issues

Asbestos-free, calcium silicate product

Does not support mold growth or absorb water

Submitals by ZHM's respresentative for Burn Room Liner

1.Submit [3] sets of cut sheet information on the burn room liner.

2.Submit [3] sets of MSDS reports on all applicable materials to be used as burn room liner.

3.Submit [3] 75x75mm samples of burn room liner material.

4.Submit [3] sets of burn room layout drawings including ceiling layouts, wall layouts, and any necessary details.

Miscellaneous Submittals for Burn Room Liner

1.Submit [3] sets of cut sheet information on all applicable additional materials including rappelling anchors, shutter slam latches and handles, temperature sensing and indicating system, shingles, felt, plywood, color charts, and any other materials included as options.