10000P Stadia Arena Papua New Guinea | Steel Structure Stadium Building | ZHM,China Manufacturer Factory Supplier

The structural steel stadium arena is mainly used for track and field competitions, and a particular plastic track is laid inside. The stadium covers an area of 25,000 square meters and can accommodate nearly 10,000 people watching simultaneously.

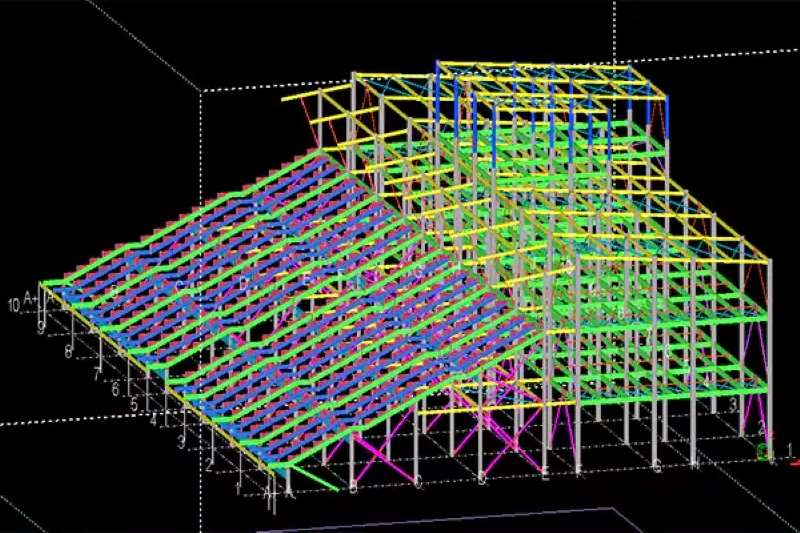

ZHM Huawu Steel was mainly responsible for designing, detaling and manufacturing the stadium’s steel structure viewing platform and top roof cantilver canopy atrium steel frame structures.

In addition to hosting sports activities, the stadium is open to the public to receive surrounding citizens and has become a major sports venue Center for citizen fitness and team building activities.

- Location: Western Highlands Province,Papua New Guinea

- Project Name: Papua New Guinea Steel Structure Stadium | Outdoor Arena Building

- Project Types: Commercial , Infrastructure , Sports, Recreation, Gymnasium

- Style: Modern

- Size: Approx. 232,000 sq. meters

- Year Completed 2020

- Shared by: Project Status:Completed

- Room or Space: Outdoor , Patio

Project Description

ZHM Huawu Steel Arena Stadium Building project in Papua New Guinea was mainly divided into three parts:

1, Stadium in Papua New Guinea project Phase 1(Main Stadium Building)

Including the following material grade applied in this steel structure project:

*Secondary steel structures Q235, including the rafter, bracing, stairs, etc, Shop blasting SA2 1/2, and prepainted with 75 micron epoxy zinc rich primer 1 coat. Top Finish Coat to be made as site after installations by Construction company.

* Bolts: High strength Grade 10.9 and Grade 8.8

2, Stadium Arena in Papua New Guinea project Phase 2(Kagua Stadium)

Including the following material grade applied in this steel structure project:

*Secondary steel structures Q235, including the rafter, bracing, stairs, etc, Shop blasting SA2 1/2, and prepainted with 75 micron epoxy zinc rich primer 1 coat. Top Finish Coat to be made as site after installations by Construction company.

*Bolts: High strength Grade 10.9 and Grade 8.8

3. Stadium in Papua New Guinea project Phase 3(Mini Stadium)

Including the following material grade applied in this steel structure project:

*Secondary steel structure Q235, including the rafter, bracing, stairs, etc, Shop blasting SA2 1/2, and prepainted with 75 micron epoxy zinc rich primer 1 coat. Top Finish Coat to be made as site after installations by Construction company.

*Bolts:High strength Grade 10.9 and Grade 8.8

*simple steel sheet:thickness=0.5mm, type=HV 820 Hidden Lock Type Corrugated Roof Panel with Clamps (Compatable with future Solar PV Panels and their subsequent steel frame system)

* Composited Galvanized Corrugated Steel Floor Decking Sheet :thickness=1.0mm, type=720 With Shear Stud M16/M19x100mm

4. ZHM Huawu Steel Execution Time Schedule:

Detailing time: 7 days, Fabrication: 30 days, Packing: 2 days.

Packing: Steel pallet for steel frame a 34*40’HQ containers

Why ZHM Huawu Metal sports venue Center stadium’s steel structure audience platform and top roof cantilver canopy atrium steel frame structures ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM Huawu Steel's Metal sports venue Center stadium’s steel structure audience platform and top roof cantilver canopy atrium steel frame structures ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com