Steel Structures Fabrication Capabilities

Steel Structures Fabrication Capabilities

Forming . Cutting . Machining . Welding . Blasting . Painting . Galvanizing . Testing

ZHM Huawu Steel wide array of fabrication and welding capabilities provides a one-stop solution for all your requirements.

Offered by ZHM Huawu Steel are state-of-the-art equipment, with skilled and qualified operators. Below is a showcase of some of the machinery offered in ZHM Huawu Steel's prequalified mills:

|

Machining, Cutting & Drilling Welding Press Brake Forming Pipe Forming Blasting, Coating & Galvanizing Testing (Material, Weld, Coating, Dimensional) Engineering Other components |

Pontoon Loadout

Machining, Cutting & Drilling

- High Precision CNC lathes turning of pieces up to 2.5 metres length

- Flame, Laser & Plasma Cutting of plates up to 150mm thickness

- Precision drilling, milling and boring

- Plate Shearing machines (up to 6 metre width and 10mm thickness)

- Automated edge bevelling for weld preparations

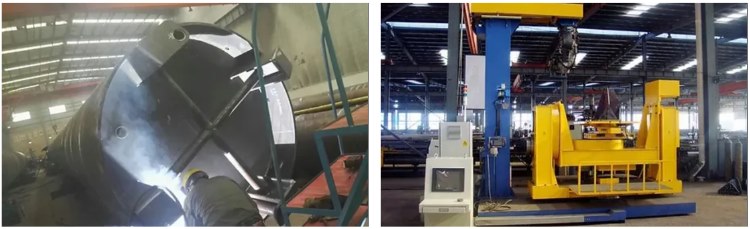

Welding

- Welding of various materials and special steel grades

- AWS qualified weld inspectors

- International Standards & Welding Codes: AWS, ASME, API, AS/NZS, CSA, BS, ISO, CEN

- Manual, Semi-auto, automated welding

- All welding technologies: SAW, MIG/MAG, TIG, FCAW, SMAW, GTAW, MCAW, GMAW

- Access to hundreds of qualified and skilled welders

- State of the art non destructive testing (NDT) and destructive testing

Skilled Manual Welding

Robotic Welding Machine

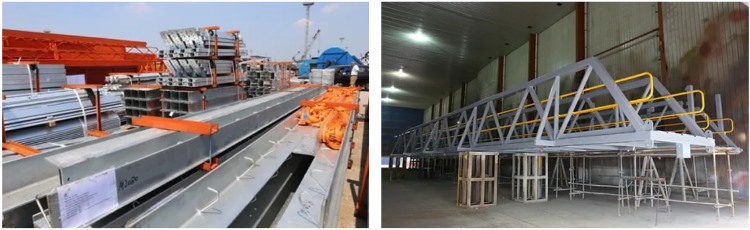

Pipe Production

- Double Submerged Arc Welded Pipe (DSAW - UOE method, JCOE method), Spiral Welded, seamless and more

- ASTM, CSA, API, BS EN, ISO standards

- Diameters can range from 1 inch (25.4mm) all the way up to 14 feet (4267mm)

- Thicknesses - between 2.10mm to 4 in (100mm)

- Lengths - all up to 100 metres length for large diameter pipes

- Various Steel Grades from S355JOH to X60 for example

- In-house hydrostatic pressure testing facilities

SSAW pipe forming

Press Brake Forming

- Lengths - up to 60' (4 metres)

- Up to 20,000mT bending force

- Thicknesses up to 1" (25.4mm)

- Large range of press brake tooling

- Large throat area for a wide range of forming dimensions

- Semi-automated material handling for efficient and safe forming

Blasting, Coating & Galvanizing

- A combination of manual and semi-auto application methods for consistent thickness and ability for application in hard-to-access places

- Blasting to various surface standards

- Various coating options - colours, types

- Careful humidity and temperature control

- ZHM Huawu Steel's certified SPCC coating inspectors supervising through the entire preparation and coating process with complete coating reports.

Paint drying

Testing

- High precision, routinely calibrated and certified dimensional measurement equipment

- ISO, OHSAS, EN 1090, ISO 3834 and other company certifications

- In-house and external material testing facilities: tensile, impact, chemical, ultrasonic

- UT, MT, RT, PT, VT testing for welds (at different percentages depending on application and project requirements). Also special methods such as

- AWS, NDT, Coating Certification of ZHM Huawu Steel QA/QC Inspectors

- Close relationships with reputable third party inspectors

- Assembly Load Testing, Pressure Testing facilities

- Coating Inspection - thickness, defects, adherence

Low Pressure Hydrostatic Testing

Coupon Testing

Paint Thickness Measurement and recording

Chemical Analysis

Impact Testing

Pressure Testing

Ultrasonic Testing

Paint Holiday Testing

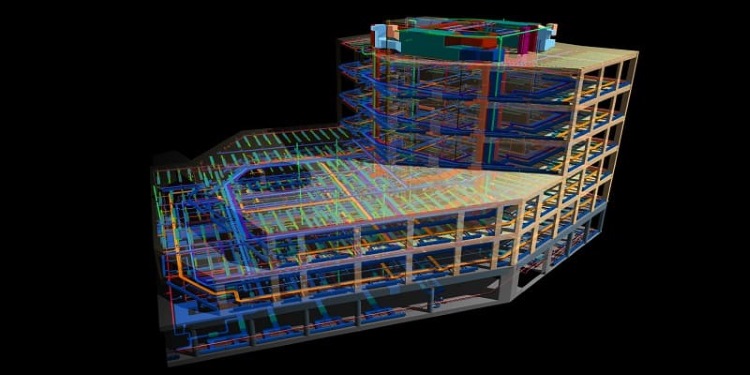

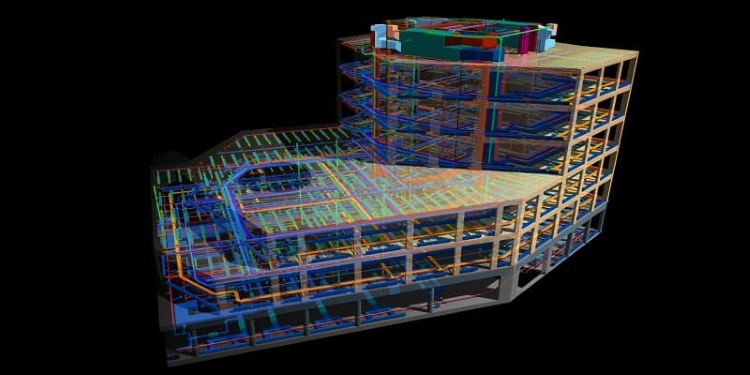

Engineering

ZHM Huawu Steel's engineering support capabilities include:

- Engineering calculations in compliance with standards

- 2D and 3D CAD Draughting for layout, shop, welding and other drawings

- Finite Element Analysis

- 3D visualisation and animation services

Useful Information

- A Basic Guide to Steel Bridges: An Engineering Marvel

- Important questions Worth Asking from Steel Manufacturers and Suppliers

- Why Trust ZHM Huawu Steel in your Steel Fabrication Projects?

- Pre-Engineered Buildings vs Conventional Buildings: Which is Better?

- Why Work with a Structural Steel Fabricator for Your Construction Project?

- What are the Applications of Structural Steel in the Construction Industry?

- Frequently Asked Questions About Structural Steel Fabrication

- Bailey Bridge

- Structural Steel Applications in Marine Construction

- Steel-Concrete Composite Construction

- Performance of Steel Buildings against Natural Disaster

- Steel Structures Fabrication Capabilities

- Application of Structural Steel in Bridges

- Advantages of Pre-Engineered Steel Building

- Safety Aspects of Structural Steel

- Steel Structures or Reinforced Concrete?

=================

Why ZHM Huawu Steel Structures Fabrication ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM’s Metal Steel Structures Fabrication ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com