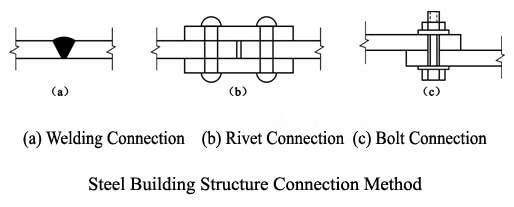

Standard Methods For Steel Building Structure Connection

Home » Steel Building » specification » Standard Methods For Steel Building Structure Connection

Table of Contents

1.Advantages and disadvantages of the welded connection

2.Welded connections have the following benefits:

3.Disadvantages of steel building structure welded connection

4.Common welding defects of Steel Structures:

5.Welding quality inspection:

B. Steel Building Structure connection-Bolting

★ Ordinary bolt connection

★ High-strength bolt connection

C. Steel Building Structure Connection-Rivet

The welded connection is the primary connection method for steel structures.

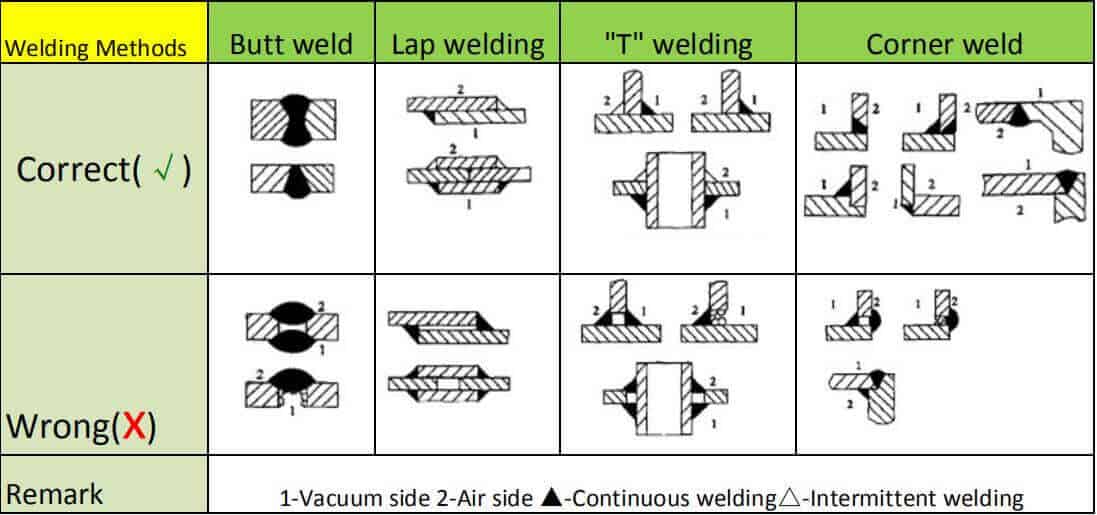

According to the relative positions of the two weldments: butt weld, overlap weld, T joint, and corner joint.

Steel Structure welding Connection

Welded connections have the following benefits:

1) No need to punch holes, save labor and time; not weaken the section and can realize automatic operation;

2) Strong adaptability to geometric shapes; components of any form can be directly connected, and the connection is convenient;

3) Proper air tightness, water tightness, structural rigidity, and functional integrity.

Disadvantages of steel building structure welded connection

2) The residual welding stress makes the structure prone to brittle failure, and the residual deformation changes the shape and size of the structure;

3) Once welding cracks occur, they will quickly expand.

2.Common welding defects of Steel Structures:

3.Welding quality inspection:

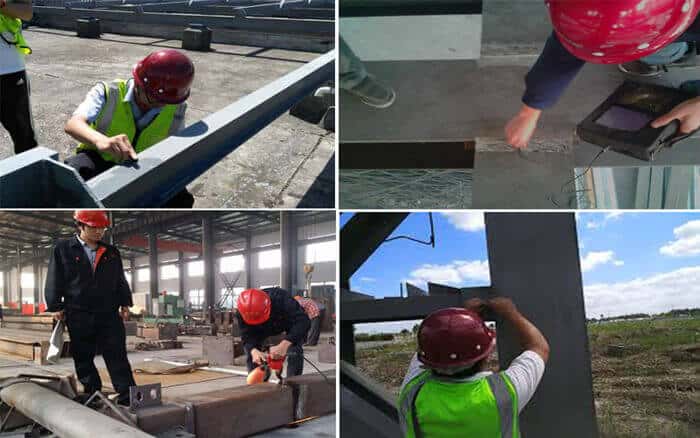

metal structure inspection

Weld quality inspection methods: visual inspection, ultrasonic flaw detection, x-ray inspection.

Weld quality classification: First-level welds must pass visual inspection, ultrasonic inspection, and X-ray inspection; second-level welds must pass visual inspection and ultrasonic inspection; third-level welds must pass visual inspection.

B. Steel Building Structure connection-Bolting

steel structure bolt connection

Ordinary bolts divided into C bolts and A, B bolts. Class A, B bolts are suitable for the installation of essential structures where large shear forces need to transmit at the connection part. And Class C bolts are ideal for temporary fixing in the erection of steel structures.

Ordinary bolts are for temporary connection and the connection of removable static load structures. Among them, Class A and B bolts rarely used at present, and high-strength bolts replace them. Therefore, the standard bolts generally refer to C bolts.

High-strength bolts divided into friction-type bolts and pressure-bearing bolts.

High-strength friction bolts currently widely used in industrial, civil construction steel structure connections. They are the most suitable connection method for bearing dynamic loads among various links. They often used in essential parts of on-site splicing and installation connections. Where structures are not ideal for welding can replace with high-strength bolts. High-strength friction type bolts are the most common bolt form in the steel structure design.

High-strength pressure-bearing bolts are tightly connected, and their bearing capacity is higher than friction-type bolts. The difference from friction type bolts is that when the pressure-bearing bolts reach the maximum bearing capacity. The connection can produce a small slippage, and the construction cost is high. Because the deformation under load is much larger than the friction type bolts. And high-strength pressure-bearing bolts mainly used for the connection of non-seismic members, non-dynamic load members, and non-repetitive action members. The rest of the connections are friction bolts.

★ Ordinary bolt connection

Advantages: convenient loading and unloading, suitable construction and simple equipment

Disadvantages: processing and installation are complicated, and the price is high when the accuracy of the bolt is high

★ High-strength bolt connection

Advantages: Friction type has small shear deformation and excellent elastic properties, and is especially suitable for structures with dynamic loads. Pressure-bearing bolts loading capability is higher than friction type, and the connection is compact.

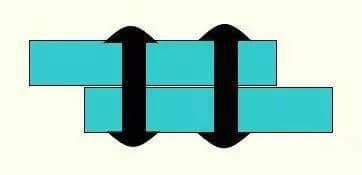

C. Steel Building Structure Connection-Rivet

A rivet is a type of tight member composed of a head and a nail rod. It mainly completes the connection work by the friction generated by its deformation. The specific connection methods include cold riveting and hot riveting.

The current building mainly adopts the hot riveting method. That is, the rivet is first heated to expand at high temperature, and then the rivet is quickly driven into the rivet hole. The rivet will shrink after cooling, but the steel plates will prevent the shrinkage deformation process on both sides.

Advantages: significant connection stiffness, reliable transmission force; simple process, stable connection, strong impact resistance

Disadvantages: high requirements for construction technology, high labor intensity, poor construction conditions, and slow construction speed. Due to its complicated structure, wasting steel and labor, it is rarely used now.

- Pre:Standard Methods For Steel Bui 2024/4/23

- Next:Steel structure splicing 2024/4/23