How To Install Metal Cladding Panel

Home » Steel Building » specification » How To Install Metal Cladding Panel

In recent years, metal buildings widely used in workshop and warehouse buildings, exhibition halls, and office buildings, which due to the low steel consumption, fast and straightforward installation, and a high degree of industrial production. It promoted the development of the metal cladding system, which from singularity to diversification, and then triggered a change in new design and installed the metal building cladding panel.

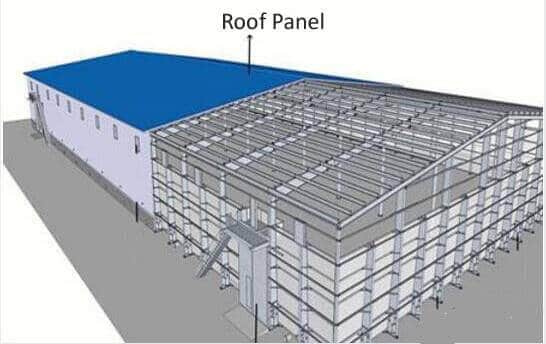

The metal cladding system of steel structure building mainly includes wall and roof panel, daylighting panel, trim and flashing, gutter, and insulation cotton. The cladding system is one of the essential components of the prefab metal structure building, which determines the ornamental appearance of the construction, the waterproofing and thermal insulation of the building.

Metal Cladding Panel

Table of Contents

1.Design and construction of the metal cladding panel systems

2.Design and construction of the daylighting panel

3.The Insulation of metal cladding panel

3.1.Advantages of rock wool sandwich panel

3.1.1.1. Fire performance

3.1.2.2. Insulation performance

3.1.3.3. Sound absorption performance

4.Eave Gutters

5. Trim and flashing

Design and construction of the metal cladding panel systems

1.Classification of the metal panel system

Metal Panel divided into the corrugated single color metal sheet, EPS sandwich boards, GRC wallboards, polyurethane(PU) sandwich boards, glass wool sandwich panel, and rock wool sandwich panel.

According to the construction method, it divides into the sandwich panel, on-site sandwich panel. On-site composite panel connection methods divided into lapboard, bite board, concealed board.

Material: galvanized color steel sheet, aluminized zinc color steel sheet, aluminum alloy profiled plate, stainless steel profiled plate,

2.Design considerations

On-site composite panels widely used in metal structure building due to their low processing cost and mature construction technology. The roof metal sheet is colorful with the 0.5mm and 0.6mm thick galvanized paint color sheet.

The roof slope affects the discharge of roof rainwater. The roof slope should be 1 / 8-1 / 20 when designing, and the more significant value should take in areas with heavy rain — besides, the roof slope related to the type of roof panel. Generally, the roof slope is substantial for the exposed nail type of board, while it is small for the hidden nail type panel.

Design and construction of the daylighting panel

The daylighting sheet is fixed with self-tapping screws and then glued and sealed. The position of the daylighting panel generally set in the span. The skylight sheet does not need to overlap within 12m. If it exceeds 12m, it needs to overlap. The overlap length is 200-400mm.

The longitudinal and longitudinal overlap of the daylighting sheet should set near the purlin. The waterproofing of the roof must be coated with sealant internally, and the surface of the sealant is smooth to age. The overlapped place uses a white or colorless sealant in the middle.

The Insulation of metal cladding panel

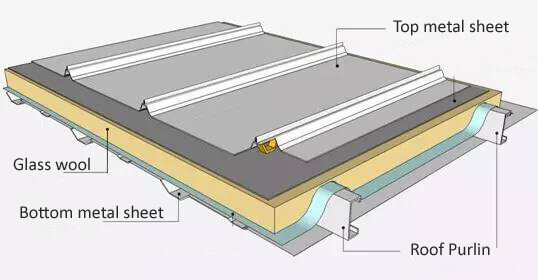

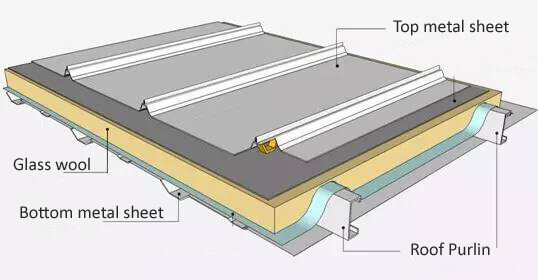

The insulation use rock wool, glass fiber, and other materials. The thermal insulation cotton has excellent thermal insulation performance, convenient construction and installation, energy-saving, and low thermal conductivity. At present, the steel structure roof system mostly adopts (1) steel wire mesh + aluminum foil insulation cotton + corrugated metal sheet, (2) double-layer corrugated metal cladding + insulation cotton.

Metal Cladding Panel

Advantages of rock wool sandwich panel

Rock wool board is used as wall and roof panel of steel structure building.

1. Fire performance

Rock wool itself is a silicate fiber inorganic material and is non-combustible. Rock wool is equipped with thermal insulation and belongs to Class A fireproof material. For a building, the importance of its fire performance is self-evident. In recent years, several major fire safety accidents have caused reflections in the building materials industry and prompted the government to make mandatory regulations on the building materials industry. In this environment, rock wool’s extremely excellent fire resistance has become the biggest advantage in competition with other insulation materials. At the same time, because rock wool is close to neutral and has excellent chemical inertness, it will not cause corrosion to the pipes and walls in contact with it. In addition, the internal structure of rock wool is loose and porous, and there are a large number of penetrating micro-channels, making it a “breathing material.” This unique property also plays an important role in maintaining the humidity balance inside and outside the building and improving the comfort of human living.

But when choosing a rock wool panel, we must pay attention to choosing the requirements that meet the national regulations. Generally speaking, the fireproof grade of fireproof rock wool panel can reach a1 and a2, while ordinary rock wool panel can only have b1. To meet the national fire protection requirements, when the temperature reaches 650 degrees Celsius, there will be no burning and safety problems, and Class A fire insulation materials must be selected.

rock wool sandwich panel

2. Insulation performance

Rock wool plays an important role in green environmental protection and energy conservation because rock wool has excellent thermal insulation properties. Thermal conductivity is an important parameter to measure the thermal insulation performance of materials. The smaller the thermal conductivity, the better the thermal insulation performance. From this perspective, the thermal insulation performance of rock wool products is 40 times that of reinforced concrete, more than 20 times that of brick-soil structures, 30 times that of cement mortar, and 3 to 5 times that of wood. An image metaphor is that if a building uses a rock wool sandwich panel for insulation, it is like a building with a cotton coat.

3. Sound absorption performance

The sound absorption of rock wool panels is mainly transmitted through the porous structure, and then the sound wave propagates. But judging from this structure, sound waves can easily cause obstacles after internal circulation. In this case, it is also a sound base. This material is absorbed by the fiber, which can better hinder the propagation of sound waves. Rock wool panel has good sound absorption performance, and the sound is at high frequency.

The following mainly introduces the construction method of steel wire mesh + aluminum foil insulation cotton + single color metal roof cladding:

Cross the stainless steel wire for a diamond or rectangular shape, lay a glass wool roll, the aluminum foil facing the indoor side, perpendicular to the purlin, and leave about 20 cm more Roll the felt and fix it to the outermost purlins with double-sided tape. Finish the glass wool with the reserved 20 cm veneer. Pay attention to the tension and alignment of the glass wool roll, and the seams between rolls are tight. When the overlap required in the longitudinal direction, the overlap joint should arrange at the purlin.

Metal Cladding Panel

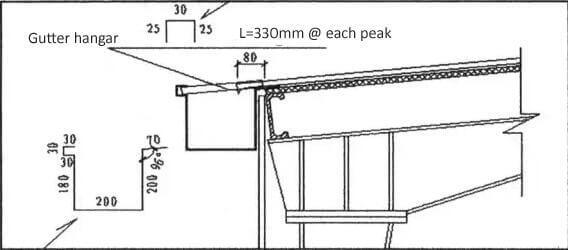

Eave Gutters

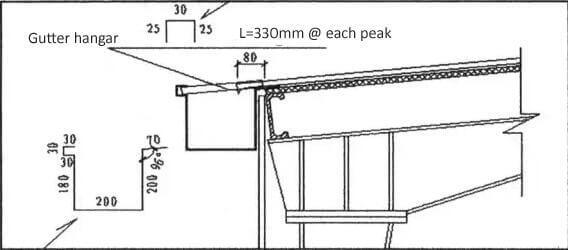

According to the structure, the cornice can divide into three forms: the outer drainage gutter, the inner drainage gutter, and the free fall. Freefall and external drainage gutter can choose preferred. According to the material, there are stainless steel gutters, steel plate gutters, and metal color sheet gutters. Gutter, as the primary drainage system of the roof, determines the function of rain and snow discharge and the regular use of the building roof.

Gutter

Trim and flashing

Trim and flashing not only outline the building, make the metal building more beautiful, but also connect the building as a whole on the structure, which is windproof and rainproof, making the building more durable.