Steel Structure Workshop Building

The Steel Structure Workshop building is increasingly used in modern industrial production. Some of the products produced by the manufacturers go directly to the market, but most of the products have stocks, which require a particular inventory in the warehouse. The fundamental difference between the factory and warehouse buildings is not much, just one for production or storage. Nowadays, the use of the steel structure workshop is also more and more extensive, so how to build a qualified steel structure workshop, we are ready to start with the various processes of Steel Structure Workshop Construction.

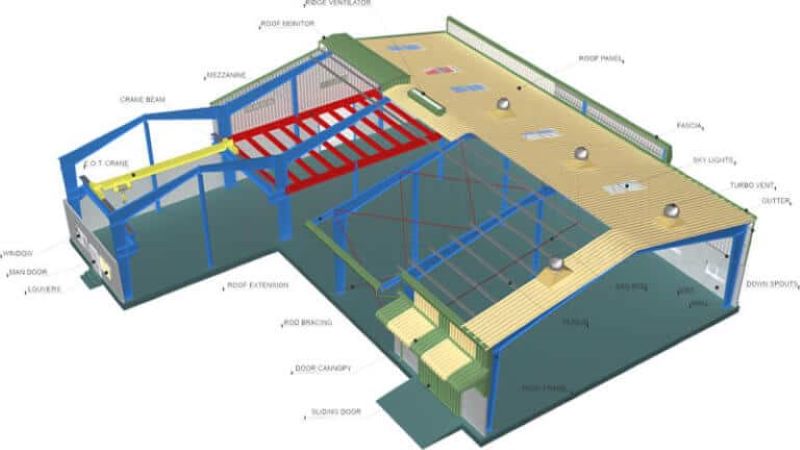

steel structure warehouse

Table of Contents

1.1.The Production Process

1.2.The Installation Process

1.2.1) Hoisting of the main structure

1.2.2) The installation of the secondary structure

1.2.3) The installation of the roof panel and insulation

1.2.4) The installation of the wall panel

1.2.5) The installation of trim and flashing

1.3.Why build the steel structure workshop?

1.4.The advantage:

1.5.The disadvantage

1.6.Single-story Steel Structure Workshop Building:

1.7.The characteristics and application of steel workshop building:

2.Design points of single-story steel structure workshop

3.Structural layout principles of single-story steel structure workshop:

3.1.Multi-story Steel Structure Workshop

3.1.1.When designing the layout, take note of the following technical points:

4.Features of multi-story steel structure workshop:

5.Advantages of multi-story steel structure workshop

5.1.Structural combination type of multi-story Steel Structure Workshop:

The processes of Steel Structure Workshop Building:

1. Design: design is the source of all working procedures; thoughtful design can make construction twice as fast, and only with the design scheme construction personnel can have a direction.

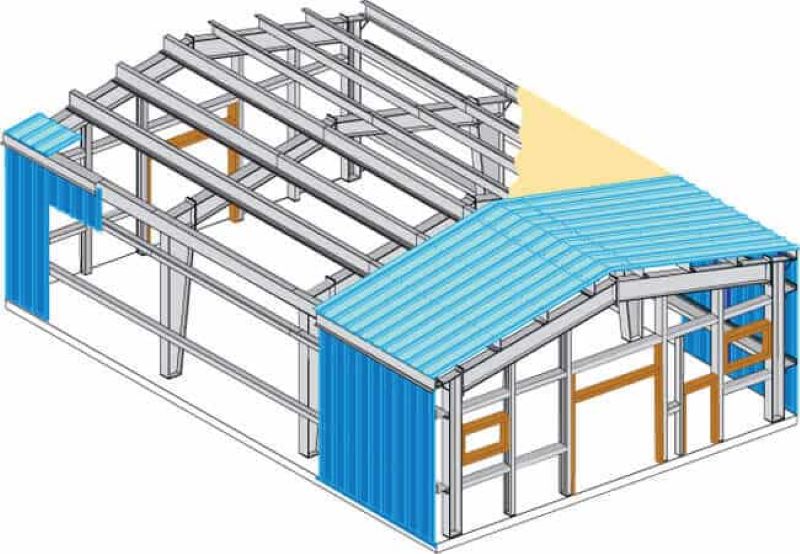

2. Production: Production follows the design of the processing of steel components.

Steel Structure Workshop building

The Production Process

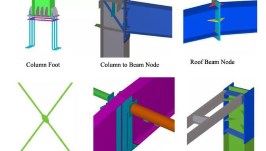

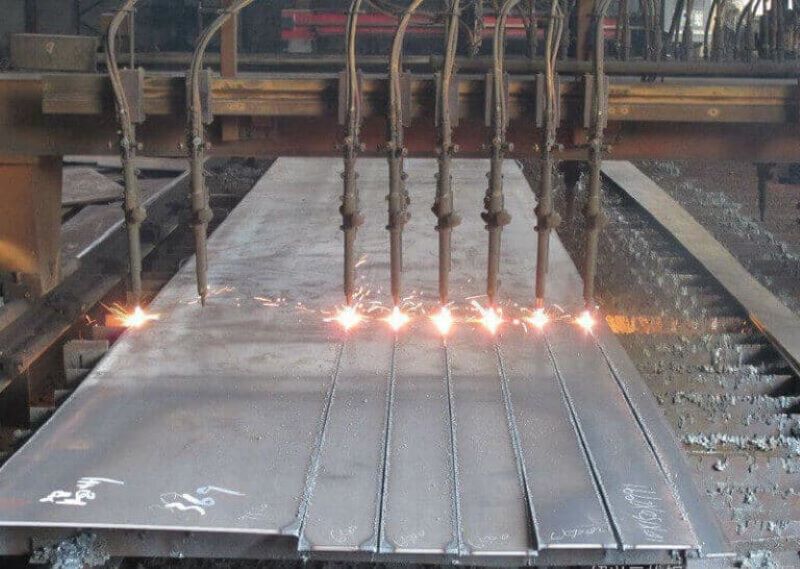

1)Cutting

steel cutting

2) Welding

steel structure welding

3) Painting

steel structure painted

The Installation Process

1) Hoisting of the main structure

Main Control Quality: the main structure deviation should meet the specifications and design requirements, and high-strength bolts should meet the needs of the steel structure workshop.

steel structure installation

2) The installation of the secondary structure

3) The installation of the roof panel and insulation

The leading control quality: the roof is primarily waterproof, so to see the board and board lap joint, nail case, the glue coating is complete, the glue place should be wiped clean, and the plate surface coating should not destroy to prevent rust, etc.

installation of roof panel

4) The installation of the wall panel

It is the insulation and wall panel installation of the steel structure workshop.

5) The installation of trim and flashing

Why build the steel structure workshop?

The advantage:

Using a steel structure to build the workshop building is very reasonable to save costs. The manufacturer of the Steel Structure Workshop components can realize the industrialized production with high precision and only need to transport to the construction site for installation; the construction steps that need to process to the construction site are simplified. The constructors of the steel structure workshop should carefully examine the drawing requirements before installation, arrange the constructors reasonably, and provide a quality guarantee for the installation of the steel structure workshop.

The disadvantage

Single-story Steel Structure Workshop Building:

Steel Structure Workshop building

The characteristics and application of steel workshop building:

1. The characteristics

1) length: unlimited

2) Span: 12 ~ 50 meters clear span

3) Height: The drip water level of the single-story steel structure workshop is significant; some workshop height is 4-5 meters, some 6-7 meters, and some can be as high as 11-12 meters or higher. Generally, the higher the steel structure workshop will be more challenging to build, the cost of materials required will be more expensive.

4) Internal structure: There is a bracket workshop to load the crane, this is an essential part of industrial production; many work machinery and equipment and heavy production materials need a crane, so it must install the bracket and crane.

5) External structure: single layer color steel sheet and sandwich panel.

2. Application:

Design points of single-story steel structure workshop

Single-story steel structure workshops can be single-span or multi-span, and each span can be arranged parallel or vertical. Most workshops are rectangular, and some thermal processing workshops use a п shape.

The column spacing of the single-story steel structure workshop is usually 6 meters or 9, 12, 18 meters, etc., and the span is also 20 meters as the fundamental parameter to facilitate the finalization of the components. The height of each span of the multi-span factory building is different and should be adjusted appropriately to simplify the elements and structural processing and change the lighting and ventilation effects.

Structural layout principles of single-story steel structure workshop:

1. Lateral anti-lateral force system

2.Carrying capacity

3.Stability

Multi-story Steel Structure Workshop

Multi-story steel structure workshops are generally composed of columns, beams, floor structures, support structures, wall panels, or frames. The multi-story steel structure adopts a plane rigid floor to ensure the space’s overall rigidity and the area’s coordination. The transverse edge is a column-support system and uses a plane rigid floor. Multi-story steel structure workshops are also widely used in the design of workshops. It can take full advantage of the stiffness of beams and columns used in any situation in a standard factory building, but when the columns are rigidly connected to the beams, the bearing capacity of these columns becomes greater by bending the frame to resist horizontal and vertical loads.

Multi-story Steel Buildings

When designing the layout, take note of the following technical points:

2. The rigid plane floor should be adopted to ensure space integral rigidity and coordinate work. When the transverse frame is the column-bracing system, the space between columns is not more than 40m.

3. Reasonable arrangement of column distance and beam system, uniform LongitudinalLongitudinal and transverse stiffness, special force transmission, uniform type of members, simple joint structure, and easy construction.

4. The steel column and its bracing can change the cross-section along the vertical direction, but the sudden change of inter-story stiffness should prevent.

Features of multi-story steel structure workshop:

2.The steel structure components are processed in the factory and have high reliability.

3.The raw materials of the multi-story steel structure workshop have good shock and impact resistance.

4.The steel structure workshop has lightweight and has a small footprint, all of which increase the actual usable area.

5.The steel structure can be assembled quickly and accurately, shortening the construction period.

Advantages of multi-story steel structure workshop

The production of the multi-story steel structure workshop is carried out on different elevation floors, with a horizontal connection between each floor and a vertical connection. Therefore, in the design of the factory building, it is not only necessary to consider the reasonable connection between the sections on the same floor and to solve the vertical connection between floors and arrange the traffic in the vertical direction.

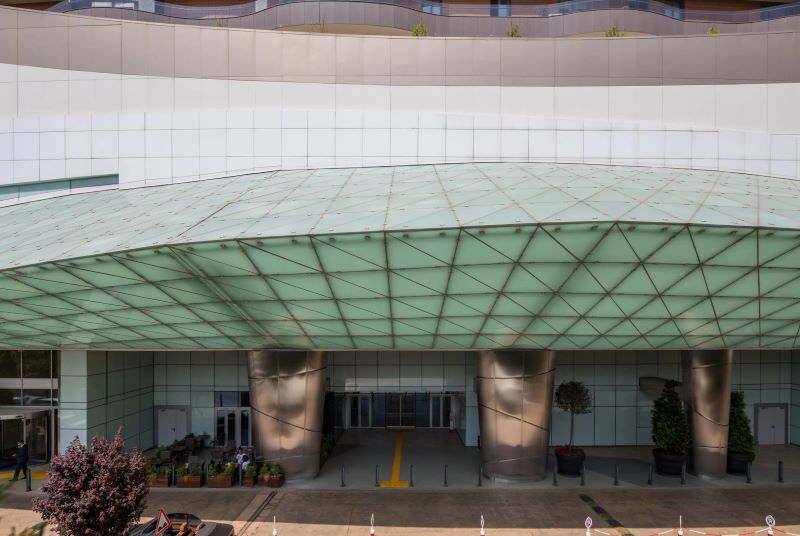

1.Beautiful and practical: The lines of the multi-story steel structure building are simple and smooth, with a modern sense. Colored wall panels are available in various colors, while other materials can be used for the walls, allowing for greater flexibility.

2.Simple construction and short construction period: All the components needed to build a multi-story steel structure building are prefabricated in the factory and only need to be simply assembled on the construction site, thus significantly shortening the construction period, a building of 6000 square meters, The basic installation can be completed in just 40 days.

3.Reasonable cost: The multi-story steel structure building is light in weight so that the essential cost can be reduced, the construction speed is fast, and it can be completed and put into production as soon as possible, and the comprehensive economic benefit is much better than that of concrete structure buildings.

4.Durable and easy to maintain: multi-story steel structure buildings can resist harsh weather and only need simple maintenance.

5.Save land: The multi-story steel structure workshop has the characteristics of a small footprint and land saving. For example, a single-story factory building with a construction area of 10,000 m2 needs an area of 10,000 m2. If it is changed to a five-story multi-story factory building, its floor area is only 20,002 m2, which is more economical than a single-story factory building. Four-fifths of the land.

6.Save investment: reduce the cost of civil construction. Since the multi-story workshop occupies less land, the amount of earthwork for the foundation is reduced, the roof area is reduced, and the cost of roof gutter, rainwater pipe, and outdoor drainage works is also reduced accordingly.

7.Shorten the road and pipe network in the factory area: the multi-story factory building occupies less space, and the factory area is also reduced accordingly. The length of various process pipelines such as railways, highway transportation lines, and water and electricity in the factory area can be shortened, saving part of the investment.

Structural combination type of multi-story Steel Structure Workshop:

(1) Steel frame system:

steel frame structure

(2) column-bracing system:

steel frame structure

(3) frame-bracing system

(4) frame-bracing composite system.

The floor forms of the multi-story Steel Structure workshop are galvanized metal bearing plate, steel frame beam and precast cement plate, steel frame beam and pattern steel plate, steel frame beam, and wood plate.

Related Posts

Would you like to see more information and images of ZHM’s Metal Steel Structure Workshop Building ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com