RAAF Aircraft Hangar HDG Steel Structures- Australia

No Pics.

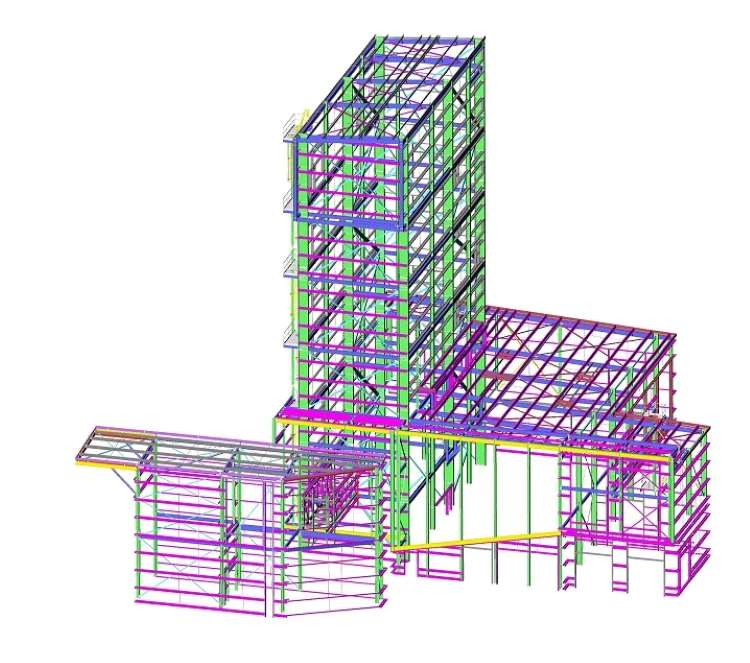

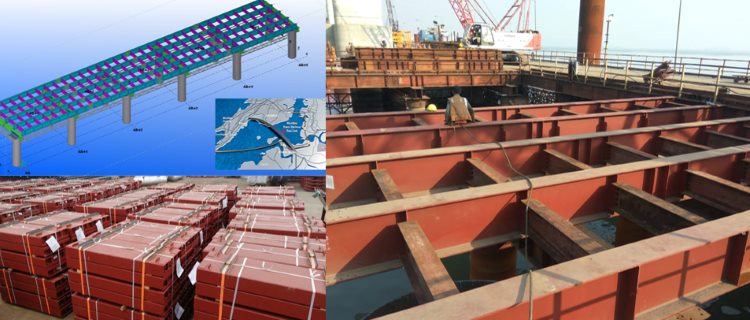

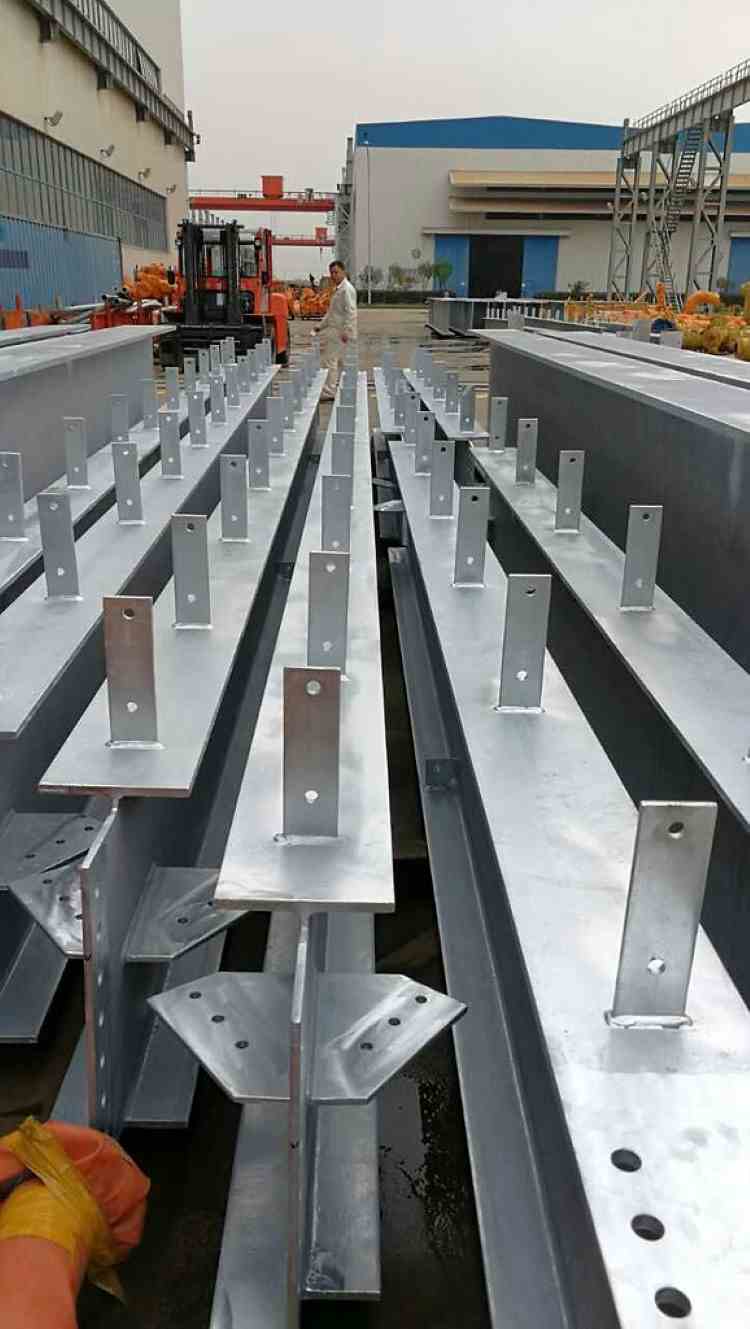

ZHM Huawu Steel was contracted by one of its regional partners in Australia to produce over 500 metric tons of structural steel prefabricated building system for an aircraft hangar to be used for the Pilot Training Systems Centre in Australia.

Prior to production, ZHM Huawu Steel completed a comprehensive Inspection & Test Plan (ITP) with a breakdown of all the processes which included: welder qualification review, raw material inspection, component dimensional inspection, weld inspection and coating inspection. Strategic review, witness and certify hold points were incorporated for each of the stages. A 3rd party inspector SGS representative was selected for the project as well by ZHM Huawu Steel and accepted by the client. After several iterations working with both the project client and consultant, the ITP was agreed and approved well before production started.

ZHM Huawu Steel successfully completed the full steel fabrication in May 2017.

Why ZHM Huawu Steel pre-engineered prefabricated aircraft hangar buildings ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM’s Metal Steel Structure pre-engineered prefabricated aircraft hangar buildings ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com