Design Criteria of Reefer Rack Yard Cvil, Foundation and Structures

No Pics.

Design Criteria of Reefer Rack Yard Cvil, Foundation and Structures

1. Design Life & Maintenance Interval

| Description | Design Life |

Maintenance Interval |

|

25 years

|

25 years

|

|

|

Paint for the passages/hot dip galvanized coating for the racks

|

25 years

|

15 years |

|

50 years

|

50 years |

(Reefer Tunnels and Reefer Passages between stacks and reefer racks)

2. Guarantees

|

Element/Product

|

Minimum Guarantee Period

|

|

Reefer frames (structure and fittings)

|

5 years

|

3. Design Criteria Tables

|

Reefer Rack Type

|

Container type

|

Container

handling

equipment

|

Rows

|

Tiers

|

Single or

Double

Sided

|

|

[A1]

|

9’6

|

ARMG

|

9 | 5 | Single |

|

[A1]

|

8’6

|

ARMG

|

9 | 3 | Single |

4. Reefer Rack Geometry and Requirements

|

Parameter

|

[A1]

9’6 9x5

|

[A2]

8’6 9x3

|

|

Single / Double Sided

|

Single | Single |

|

Overall steel frame length (mm)

|

24480 | 24480 |

|

Overall steel frame width (mm)

|

1700 | 1700 |

|

Floor height, FFL to FFL per floor (mm)

|

2900 | 2600 |

|

Ground level floor height, FFL to FFL (mm)

|

2900 | 2600 |

|

Number of reefer plugs

|

One per container plus one

spare per level

|

One per container plus one

spare per level

|

|

Location of reefer plugs

|

One side only, 1000-1400

above FLL

|

One side only, 1000-1400

above FLL

|

|

Maximum permissible steel frame height (mm)

|

14480 | Not applicable (N/A) |

|

Clearance from steel frame to containers, plug side (mm)

|

400 |

400 |

|

Clearance from steel frame to containers, non-plug side (mm)

|

600 nominal |

600 nominal |

|

Clear distance between containers (mm)

|

350 | 350 |

|

Clearance from end of steel frame to end of last container (mm)

|

150(shorter) |

150(shorter) |

|

Minimum clear width of stairs (mm)

|

700 | 700 |

|

Transverse position of stairs

|

Non-plug side

|

Non-plug side |

|

Minimum clear width of platform at any location (mm)

|

700 | 700 |

|

Provision for pavement slope

|

1% ± 0.5%

|

1% ± 0.5%

|

|

Roof required on top level

|

Yes

|

Yes |

|

Bollards required at each corner

|

Not applicable (N/A) |

Not applicable (N/A) |

|

Paint colour

|

Not required (galvanized only)

|

Not required (galvanized only)

|

|

|

|

|

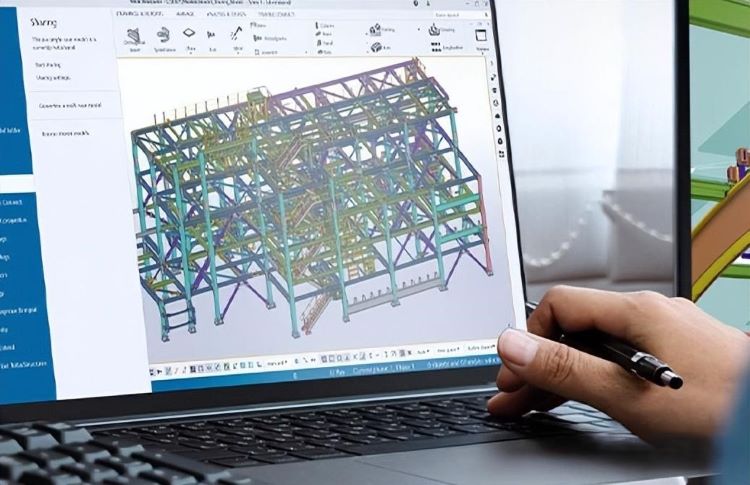

(Reefer Tunnels and Reefer Passages between stacks and reefer racks 3D Isometric View)

5. Reefer Rack Design Loads

|

Parameter

|

Value

|

|

Dead Load

|

Self-weight of the structure

|

|

Superimposed Dead Load

|

Self-weight of electrical equipment, including distribution boards,

cable trays and cabling, etc.

|

|

Live Load – Flooring

|

UDL: 1000 kg load over any 4 m2 , i.e. any sector of 4 m2 shall be

able to withstand 250 kg/m2 , and the whole platform will not be

loaded with more than 1000 kg total.

Point load: All surfaces and steps shall resist 450 kg point load

over an area of 200 x 200 mm at any point, with deflection not

greater than 10 mm during application and with no permanent

deformation

60kg vertical load in the most unfavourable location and 75kg

horizontal load in the most unfavourable location (loads not

applied simultaneously)

|

|

Live Load – Handrails and

Parapets

|

deflection not greater than 15 mm during application and with no

permanent deformation

|

|

Operational Wind Speed

|

Refer Part A “General Project Considerations

|

|

Storm Wind Speed

|

Refer 01 Part A “General Project Considerations

|

|

Seismic Load

|

Importance Factor: 1.0

Refer Part A “General Project Considerations” for other parameters

|

6. Reefer Passage Requirements

|

Parameter

|

Value |

|

Superimposed Dead Load

|

Weight of up to 4 No. fully laden containers (up to 35 t each)

placed on top via corner castings

(1st container will be 35 t buffer container filled with sand + 3 fully

loaded containers on top)

|

|

Dynamic Load

|

Weight of 1 fully laden container (35 t) to be considered with a

minimum factor of safety of 2.0 (in addition to the superimposed

dead load).

Alternative methods to allow for the dynamic load from container

placement may be considered in accordance with adopted codes,

subject to approval by the Engineer.

|

|

Live Load – Flooring

|

2.0 kPa

|

|

Operational Wind Speed

|

Refer Table 5 as above listed |

|

Storm Wind Speed

|

Refer Table 5 as above listed |

|

Seismic Load

|

Refer Table 5 as above listed |

|

Container Impact Load

|

Minimum 50 kN (from a fully laden container) to be applied to the

structure as a point load at various locations and in various

directions to suit the container handling equipment. These point

loads shall not be applied simultaneously.

The structure may be damaged by this impact but the damage

shall be repairable with the replacement of the impacted elements

but the structure shall not collapse under the impact of the

loading.

This load case shall not be considered in combination with other

loads (except dead loads)

|

|

|

|

Note: Structural reinforcement shall be provided at each end of each passage, to resist the loads listed above in Table 6. As a minimum, each vertical column shall have at least the same structural capacity as the unmodified container corner posts, the horizontal beams shall have at least the same structural capacity as the unmodified container beams, and diagonal bracing shall be provided in the top corners for torsional restraint.

7. Reefer Rack Foundation Requirements

|

Parameter

|

Value

|

|

level projection above

surrounding ground level

|

• Arid / low rainfall environment: Flush with surrounding

pavement

• Heavy / frequent rainfall environment: 200mm above

surrounding pavement

• For converted containers: Flush with surrounding pavement

• Raised floor to prevent water or frozen puddles.

• Reduced steps as much as possible.

• The level of the foundation is flush with ground level for the

stacks that are being prepared only. Other foundation levels

to be included in overal height first (ground) level of the

racks.

|

|

Design Loads

|

• Loads to be defined by reefer rack designer, including but not

limited to:

o Maximum vertical compression at the base of each column

o Maximum vertical uplift at the base of each column

o Maximum horizontal shear at the base of each column

o Maximum bending moment at the base of each column

o Overturning effect (bending moment) on the base slab

from each pair of columns

• Live load on ground level = 2.0 kPa

• Dead load of any electrical equipment to be considered, where

relevant

|

|

Holding Down Bolts

|

Bolt arrangement, size and embedment length at each column to be defined by reefer rack designer

|

|

|

|

Would you like to see more information and images of ZHM’s Metal Steel Structure Reefer Racks ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com