The Spec of Steel Frame Building

A steel frame building is a load-bearing framework composed of steel columns and steel beams fabricated by section steel or steel plates. The steel columns and steel beams are connected by bolts or welding, usually rigid connections.

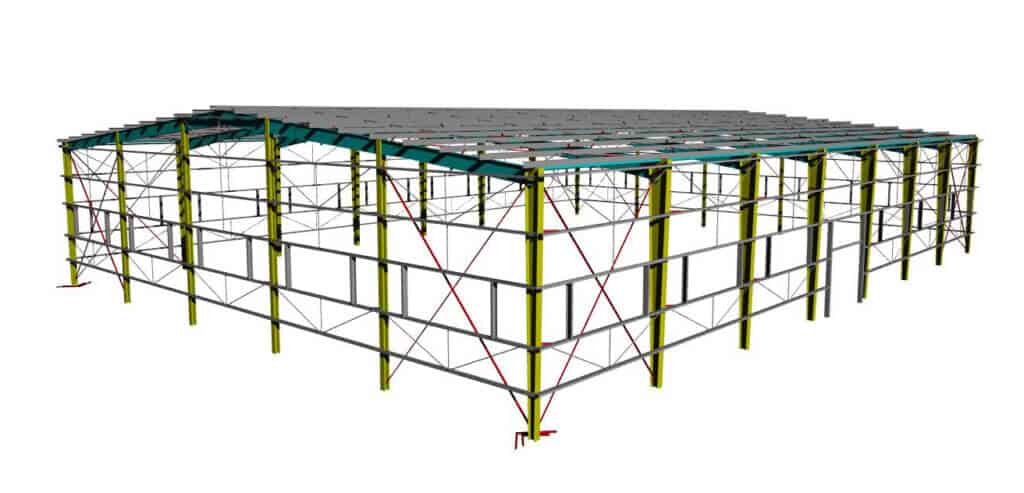

Steel frame building composed of welded H-shaped steel and hot-rolled H-shaped steel as the main load-bearing skeleton, and C and Z section steel used for purlins and walls girt. The corrugated metal sheet use for roof and wall panels. Polystyrene foam, rigid polyurethane foam, rock wool, glass wool use as thermal insulation materials, and appropriate bracing light steel structure building systems.

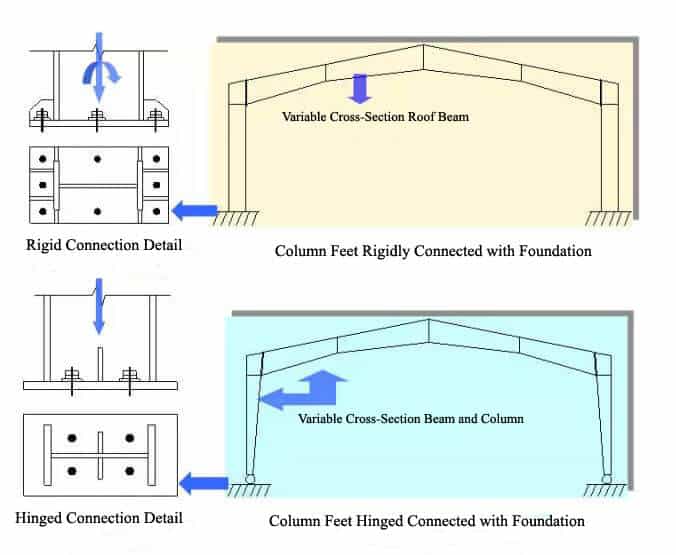

The Beam and column of portal steel frames use welded h-shaped variable cross-section members. The beam-column joints of single-span portal frames rigidly connected, the multi-span portal frames are rigidly and hinged connected, the column feet can be rigidly or hinged connected with the foundation. The wall and roof panel use corrugated metal sheets. Thermal insulation materials used glass wool.

steel frame detail

Table of Contents

2.Structural Arrangement:

2.1.The arrangement of Portal Steel Frame Building

2.2.The arrangement of Purlin and wall girt

2.3.The arrangement of Bracings and Tie beam

2.4.Loads and load combinations

2.4.1.Permanent load

2.4.2.Variable load

2.4.3.Load combination

2.5.Precautions in the design of Steel Frame Building

2.6.Precautions for Steel Structure Fabrication

2.7.Precautions for The Installation of Steel Brame Building

2.7.1.The advantage of Steel Frame Building over Concrete Structure:

The forms of portal steel frame building:

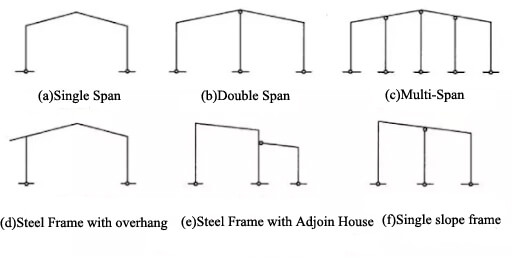

The structural form of portal steel frames divided into the single span, double-span, and multi-span according to the span, and single ridge single slope, single ridge double slope, and multi-ridge multi-slope according to the number of roof ridges. The slope of the roof should be 1/20 to 1/8.

steel frame building

Structural Arrangement:

The arrangement of Portal Steel Frame Building

The arrangement of Purlin and wall girt

steel frame building

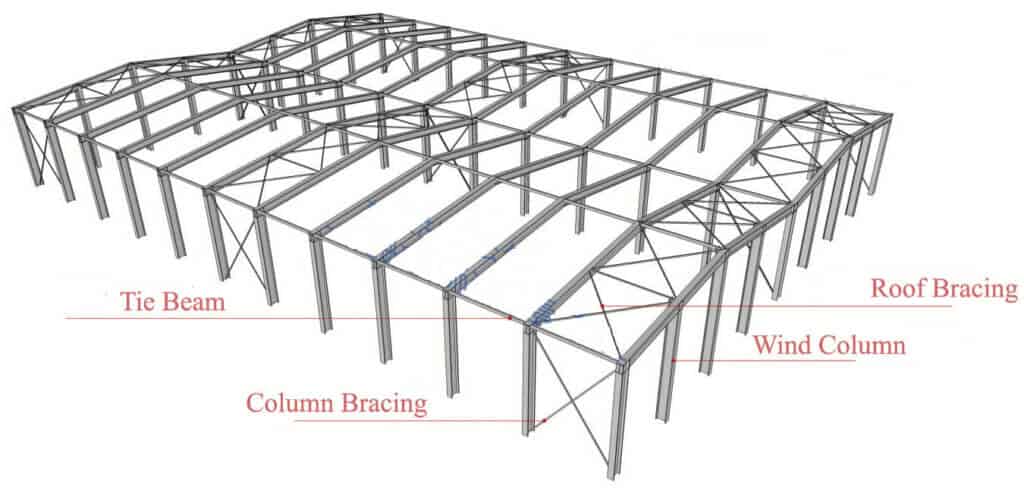

The arrangement of Bracings and Tie beam

steel frame building

2.In setting up the opening of the column bracing, the lateral bracing of the roof should be set at the same time to form a geometrically invariant system.

3.The end bracing located in the first or second opening at the end of the temperature zone. The spacing between column bracing determined according to the longitudinal force of the building and installation conditions, generally 30 ~ 45m, and no more than 60m if with a crane.

4.When the building is very tall, the column bracing should set in layers. When the width is over 60m, it needs to set column bracings.

5.When the end bracing located in the second opening of the end, rigid rods shall place in the corresponding position of the first opening.

6.At the turning points of the steel frame, the tie beam needs to set along the entire length of the building.

7.For horizontal trusses consisting of bracing slanting rods, the straight belly rods should consider according to the rigid rods.

8.Purlins can make stiff rods; at this time, the purlins should meet the load-bearing capacity and rigidity requirements of pressed bent members. If not satisfied, steel pipe, H-beam, or another cross-sectional form of the rod need set between the rigid frame inclined Beam.

9.When the building equipped with not less than 5t crane, the column bracing is suitable to use section steel. When the building is not allowed to set the column bracing, it should set the longitudinal steel frame.

Loads and load combinations

Permanent load

Variable load

Load combination

- Evenly distributed live roof loads are not considered together with snow loads, and the greater of the two should take into account.

- The ash load shall consider in conjunction with the larger of the snow load or the roofing uniform live loading.

- Construction or maintenance concentrated loads not considered in conjunction with loads other than the roofing material or purlins’ weight.

- The combination of more than one crane shall comply with the provisions of the “Design Code for Structural Load of Buildings.”

- When seismic action needs to consider, wind loads not found at the same time as seismic action.

-

Precautions in the design of Steel Frame Building

- Because the bending and torsional stiffness of the structural components of the portal steel frame is small, the overall stiffness of the structure is weak, so the design should consider the necessary measures to take during transportation and installation to prevent the bending and torsional deformation of the components.

- To pay attention to the bracing system and corner bracing arrangement, and also the roof panel, wall panels, and elements of the connecting structure, so that it can participate in the overall work of the structure.

- The rods that make up the structure member are thin. It needs to consider the requirements for production, installation, and transportation when design.

- The effect of corrosion on the weakened cross-section of structural members should fully consider in the design.

- The beam and column of the portal steel frame mostly adopt the variable section rod, the beam and column webs designed to take advantage of the bending strength, so the plastic design is no longer applicable.

- Consequences of light-weighting in the design must note and adequately addressed, such as the fact that wind can reverse the load on lightweight roof.

Precautions for Steel Structure Fabrication

steel structure fabrication

2.The steel surface after correction shall not have a transparent concave surface or damage, and the depth of scratch shall not be over 0.5mm. For gas-cut or mechanically-sheared parts, when edge machining is required, the planing amount should not be less than 2.0mm.

3.When drilling holes, the accuracy and allowable deviation of the bolt holes should comply with the specifications. When the permissible difference of the bolt holes exceeds the specs, it not allow steel block to plug. Can use the welding rod that matches the steel material to repair or re-weld to make new holes.

4.When welding, do not use electrodes with peeled coatings or rusty welding cores, fluxes and agglomerated fluxes, and welded shells. Welding wires and nails should clean of oil and rust before use.

5.When the grinding wheel treats the friction surface, the cracking range should not be less than four times the bolt hole diameter, and the grinding direction should be perpendicular to the stress direction of the component.

6.The steel structure should shot blast before coating, the coating should be uniform, without visible wrinkling, sagging, and adhesion should be excellent. After the painted completed, the number of the component should mark on the steel structure.

Precautions for The Installation of Steel Brame Building

2.When the steel structure installed with an expanded assembly unit, the strength and stability of the steel members that are easily deformed should check. If necessary, reinforcement measures should take. After all steel components installed, a spatial rigidity unit should form.

3.After the primary structure, such as columns, beams, roof trusses, and bracings of the steel structure installed in place, they should fix immediately. The installation of the steel structure should form a stable space system.

4.When installing high-strength bolts, the bolts should penetrate freely into the holes and should not use as temporary installation bolts. The installation of high-strength bolts should be tightened in a specific order, preferably from the center of the bolt group, and should do a final twist on time.

The advantage of Steel Frame Building over Concrete Structure:

(1) Lightweight

(2) The high degree of industrialization and short construction period

(3) The layout of the column is more flexible

- Pre:None

- Next:Advantages of industrial wareh 2024/5/12