Why Steel Building Need Wall Bracing

2024/4/19 view: 259

Why Steel Building Need Wall Bracing

Home » Steel Building » specification » Why Steel Building Need Wall Bracing

Wall bracing, also called column bracing, is a connecting rod set between two adjacent columns to ensure the overall stability of the building structure, improve lateral stiffness, and transmit longitudinal horizontal force.

2.The use of Wall Bracing

2.1.The arrangement of Wall Bracing

2.2.Form of wall bracing

2.3.The Materials for Bracing

It’s essential, but the column bracing cannot be ignored.

The inter-column bracing bears and transmits horizontal forces (longitudinal braking force, wind load, earthquake action, etc.) to improve the overall stiffness of the structure, ensure its overall stability, reduce the stable stress outside the steel column surface, and ensure its stability during installation. For essential purposes such as stability, reasonable support stiffness can avoid the aggravation of snow damage when snow is on the ground.

For dry steel structure factory buildings, generally, every

Each column column is arranged with inter-column supports. The support spacing between light steel factory buildings without cranes is no more than 45 meters, and between columns of steel structure factory buildings with cranes is no more than 60 meters.

Generally, supports are provided in the first bay at both ends because the function requires the first bay.

If it cannot be set, it can be adjusted accordingly. Still, corresponding rigid struts must be set up to transfer the load to the inter-column bracing; also, attention must be paid to the inter-column bracing to avoid the factory door as much as possible.

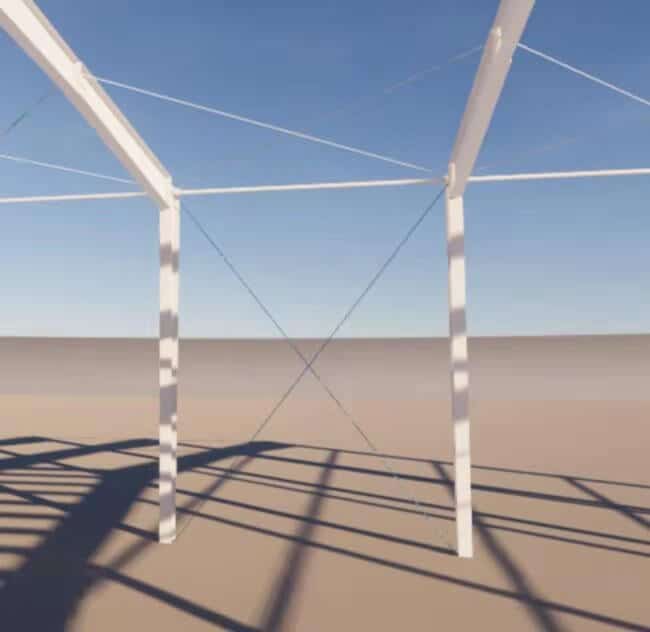

The Wall bracing is generally provided in the middle of the column. The tie beam at the top of the frame transfers the load of the roof bracing to the column bracing. If the building is more extended, additional wall bracing will be added—the bracing between the two columns is placed at 1/3 of the longitudinal direction. The column bracing can be designed as an X shape, and it can also be created as a V bracing, K Bracing, or even a portal frame.

It is best to use one type of inter-pillar bracing in the same building, and mixing several kinds of inter-column bracing is unsuitable. Due to functional requirements such as opening doors, windows, or other factors, port frame bracing or truss bracing can be used. When the bracing system must mix, the rigidity should be as consistent as possible. If the rigidity requirements cannot be met, the vertical-horizontal force of each bracing should be individually analyzed to ensure the stability and safety of the structure. At the same time, attention should be paid to the bracing set.

Generally speaking, light steel workshops without cranes can use

Crossed round bars with tensioners serve as supports between columns at angles between 30 and 60 degrees.

When the height of the factory building is not considerable, single-layer support should be used. When the height is more than 50% greater than the span, double-layer support should be used; for factories with cranes, rigid support should be used: the support members are

Steel cross bracing is generally divided into two layers (lower column support below the crane beam and upper column support above the crane beam).

In addition to angle steel, cross-bracing between columns in tall buildings can also be done using steel pipes. The steel pipe has the characteristics of saving materials, simple production, and looks reliable and beautiful in the building.

The connection nodes between the column bracing are similar to the horizontal bracing. It must be noted that the upper end of the column bracing and the horizontal pressure rod must be at a point with the column center. Similarly, the lower end of the bracing between columns should intersect the center of the column as far as possible with the bottom of the column foot to avoid eccentric forces. A reinforced concrete beam can be added below the ground if the column foot surface is higher than the ground.

Home » Steel Building » specification » Why Steel Building Need Wall Bracing

Wall bracing, also called column bracing, is a connecting rod set between two adjacent columns to ensure the overall stability of the building structure, improve lateral stiffness, and transmit longitudinal horizontal force.

Table of Contents

2.The use of Wall Bracing

2.1.The arrangement of Wall Bracing

2.2.Form of wall bracing

2.3.The Materials for Bracing

The role of column bracing

It’s essential, but the column bracing cannot be ignored.

The inter-column bracing bears and transmits horizontal forces (longitudinal braking force, wind load, earthquake action, etc.) to improve the overall stiffness of the structure, ensure its overall stability, reduce the stable stress outside the steel column surface, and ensure its stability during installation. For essential purposes such as stability, reasonable support stiffness can avoid the aggravation of snow damage when snow is on the ground.

The use of Wall Bracing

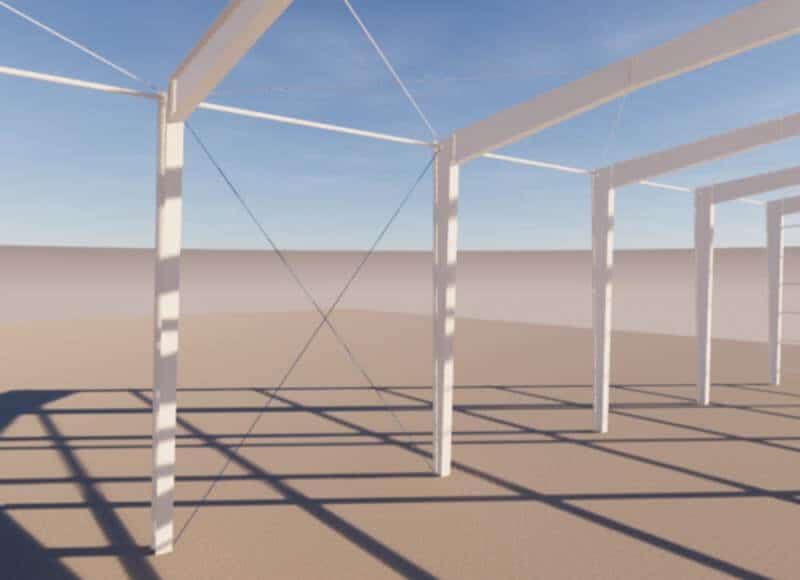

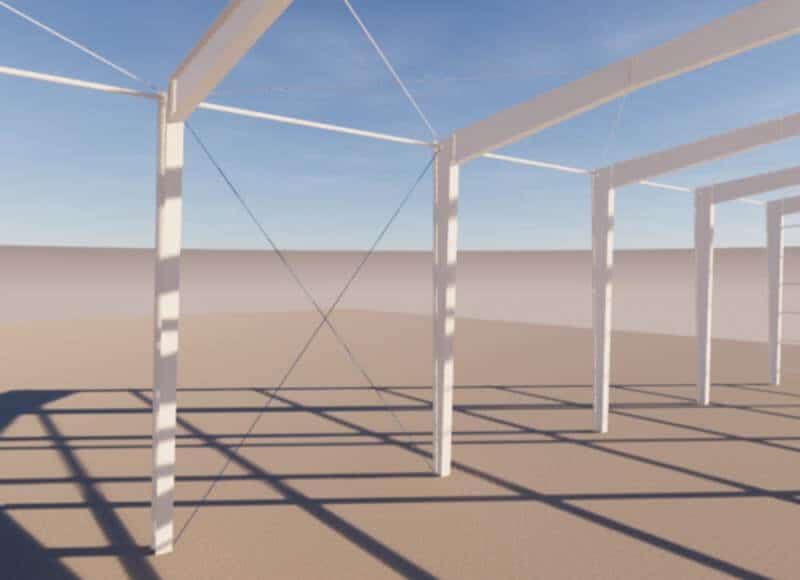

Wall Bracing

The arrangement of Wall Bracing

For dry steel structure factory buildings, generally, every

Each column column is arranged with inter-column supports. The support spacing between light steel factory buildings without cranes is no more than 45 meters, and between columns of steel structure factory buildings with cranes is no more than 60 meters.

Generally, supports are provided in the first bay at both ends because the function requires the first bay.

If it cannot be set, it can be adjusted accordingly. Still, corresponding rigid struts must be set up to transfer the load to the inter-column bracing; also, attention must be paid to the inter-column bracing to avoid the factory door as much as possible.

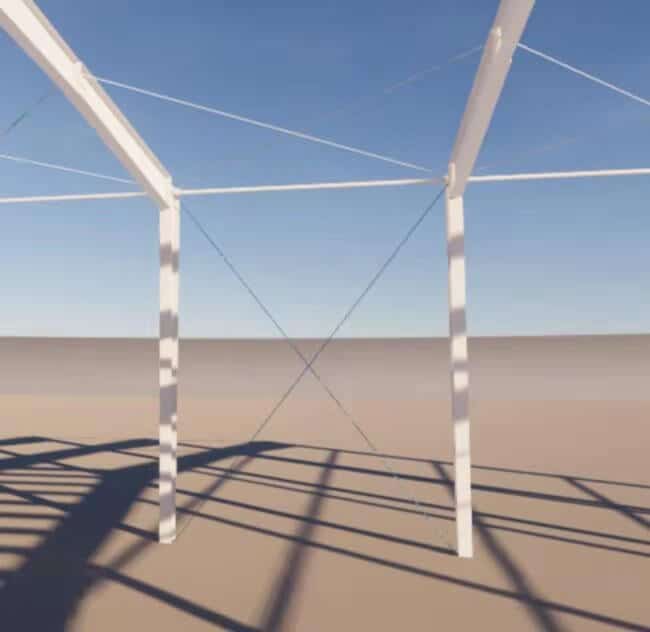

The Wall bracing is generally provided in the middle of the column. The tie beam at the top of the frame transfers the load of the roof bracing to the column bracing. If the building is more extended, additional wall bracing will be added—the bracing between the two columns is placed at 1/3 of the longitudinal direction. The column bracing can be designed as an X shape, and it can also be created as a V bracing, K Bracing, or even a portal frame.

It is best to use one type of inter-pillar bracing in the same building, and mixing several kinds of inter-column bracing is unsuitable. Due to functional requirements such as opening doors, windows, or other factors, port frame bracing or truss bracing can be used. When the bracing system must mix, the rigidity should be as consistent as possible. If the rigidity requirements cannot be met, the vertical-horizontal force of each bracing should be individually analyzed to ensure the stability and safety of the structure. At the same time, attention should be paid to the bracing set.

Form of wall bracing

Generally speaking, light steel workshops without cranes can use

Crossed round bars with tensioners serve as supports between columns at angles between 30 and 60 degrees.

When the height of the factory building is not considerable, single-layer support should be used. When the height is more than 50% greater than the span, double-layer support should be used; for factories with cranes, rigid support should be used: the support members are

Steel cross bracing is generally divided into two layers (lower column support below the crane beam and upper column support above the crane beam).

The Materials for Bracing

In addition to angle steel, cross-bracing between columns in tall buildings can also be done using steel pipes. The steel pipe has the characteristics of saving materials, simple production, and looks reliable and beautiful in the building.

The connection nodes between the column bracing are similar to the horizontal bracing. It must be noted that the upper end of the column bracing and the horizontal pressure rod must be at a point with the column center. Similarly, the lower end of the bracing between columns should intersect the center of the column as far as possible with the bottom of the column foot to avoid eccentric forces. A reinforced concrete beam can be added below the ground if the column foot surface is higher than the ground.

- Pre:None

- Next:Large Span Roof Steel Structur 2024/4/19