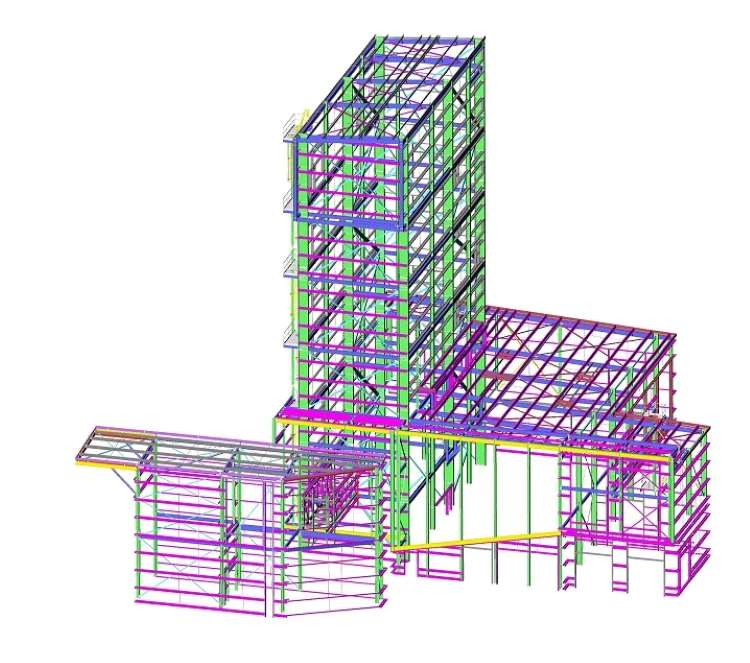

Steel Bypass Tunnel Access chambers For Rondout Tunnel Project, New York, USA

No Pics.

ZHM Huawu Steel was awarded the supply 2 sets of access chambers for the construction of Rondout west branch bypass tunnel in USA. The access chambers are manufactured in accordance with ASME Section VIII – Rules for Construction of Pressure Vessel.

The 13.5-foot-diameter (4.1 m) rock RWB Tunnel is approximately 45 miles (72 km) long, ranges in depth from 300 to 2,300 feet (91–701 m), and operates with an internal head of up to 1,200 feet (366 m). It was constructed during the late 1930s and 1940s using drill-and-blast methods. Most of the tunnel has an un-reinforced concrete liner. In areas of poor ground conditions and significant groundwater inflow during construction, steel “interliners” were incorporated in the lining system.

Since about 1970, leakage has been observed at the ground surface, especially in an area immediately west of the Hudson River near Roseton, New York. The geology in this area of the alignment is complex. The depth, from ground surface to the existing tunnel at the Hudson River, ranges from 600 to 900 feet (183–274 m).

- Constructing a bypass tunnel around the leaking areas in Roseton.

- Repair of Aqueduct in Wawarsing.

- Developing water supply augmentation projects.

ZHM Huawu Steel was awarded the supply 2 sets of access chambers for the construction of Rondout west branch bypass tunnel in USA.

The access chambers are manufactured in accordance with ASME Section VIII – Rules for Construction of Pressure Vessel.

Each set of access chambers consist of the following components:

- Shaft cap with flange

- Transition fitting with flange

- Access pipe with flange

- Other accessories (stud & nut, O-ring, and plug for telltale hole)

Fabrication Photos

Blasting and Painting

Packing & Shipping

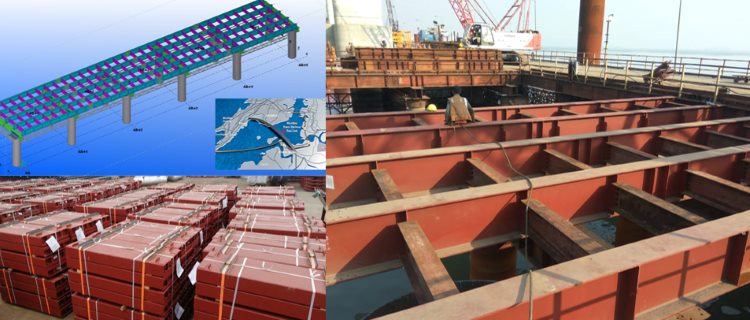

ZHM Huawu Steel fabricated and supplied 13 steel mono piles to Edgen Murray Europe. The project was part of the Mare Harbour base improvements in the Falkland Islands. Each steel mooring dolphin pile included fender mounting brackets and stiffeners, bollard supporting plates and topside deck plates.

ZHM Huawu Steel in conjunction with their regional agent Edgen Murray Europe supplied the mono-piles used as the mooring and breasting dolphins. Each pile was nearly 2.5 metres in diameter and lengths between 19.5m up to 34.8m per piece. The dolphin pile design incorporated a mounting flange for a cone fender system that weighed in excess of 15 metric tons that was each capable of absorbing over 300 ton metres with over 250 tons reaction force. Each dolphin consisted of the steel pile and an upper section bolted on to the top of the steel pile via internal flanges for the bollard and walkway deck mounting.

The service environment as classified under BS EN ISO 12944-2 was Category C5-M – Offshore Environments which is a very high marine atmospheric corrosivity category in regions with high salinity. The selected corrosion protection system for the steel dolphin mono-piles utilized a 380 microns dry film thickness approved coating.

Prior to production, ZHM Huawu Steel completed a comprehensive Inspection & Test Plan (ITP) with a breakdown of all the processes which included: welder qualification review, raw material inspection, component dimensional inspection, weld inspection and coating inspection. Strategic review, witness and certify hold points were incorporated for each of the stages. A 3rd party inspector was selected for the project as well by ZHM Huawu Steel and accepted by the client. After several iterations working with both the project client and consultant, the ITP was agreed and approved well before production started.

The production was completed successfully and was loaded to be shipped to the Falkland Islands in May 2017.

Fabrication Photos

Mono Piles Loading Photos

Why ZHM Huawu Steel Steel Bypass Tunnel Access chambers ?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM’s Metal Steel Structure Steel Bypass Tunnel Access chambers ? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com