Sharjah Footbridge Arch Steel Structures- United Arab Emirates | Made In China ZHM

No Pics.

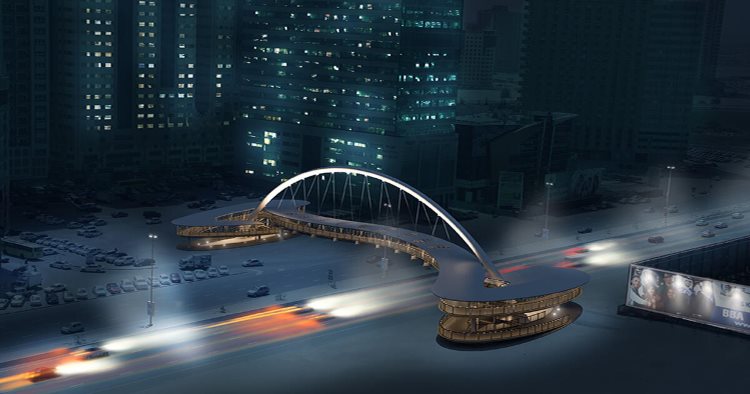

Sharjah Footbridge Arch Steel Structures in Operation in Night

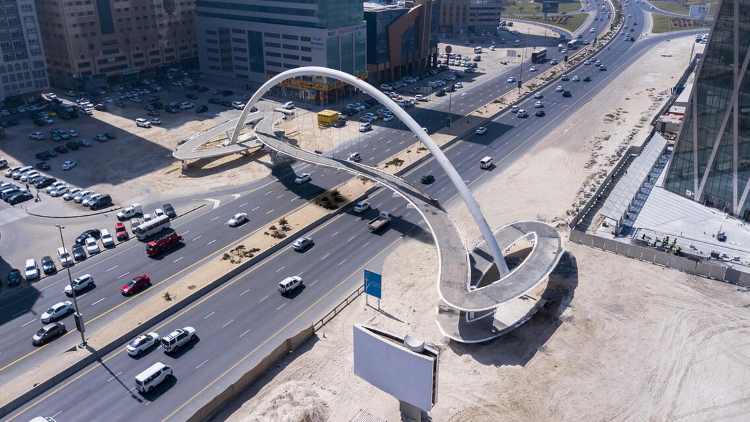

Sharjah Footbridge Arch Steel Structures in Operation in Night in day time

Al Ittihad Road Footbridge located in Sharjah, UAE is an arch suspended deck system with the curvy alignment of the walkway, fully integrated with elliptically spiral ramps placed at both ends of the bridge. Footbridge arch spans across the road by ca. 92m with a height of 26m above ground level. Width of walkway deck is 4.8m with 4m wide pedestrian clearance. The footbridge crosses Al Ittihad Road with ca. 70m wide road clearance underneath and min. 6m high clearance height under its deck. The structure provides pedestrian and cycle crossing under a shaded canopy. Crossing includes lighting and other electrical and drainage services. Installation of the bridge required keeping undisturbed traffic on Al Ittihad Road which is the main infrastructural artery linking Sharjah and Dubai.

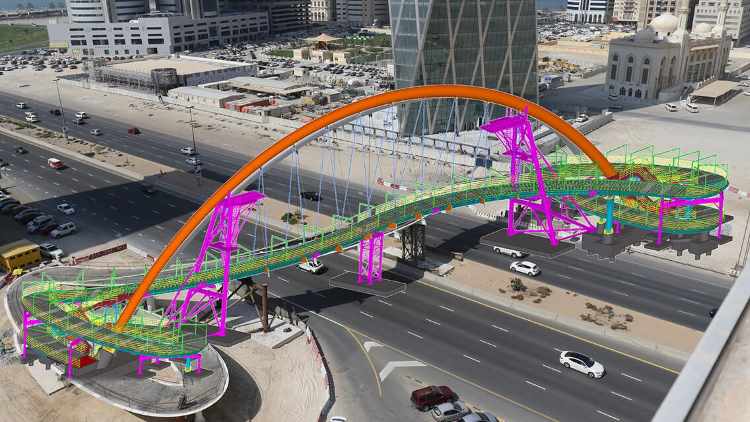

Sharjah Footbridge Arch Steel Structures under erection

Sharjah Footbridge Arch Steel Structures under erection

Sharjah Footbridge Arch Steel Structures under erection

ZHM BIM Engineering and Detailing Solution:

1) Continuous work over live traffic and with limited access on site.

2) Heavy fabrication, transportation, and installation in difficult conditions.

3) Curvy decking structure with a little number of supports required extensive temporary support design and temporary construction works.

4) Structural design is available for the final stage of the complete bridge only. Partial installation stages design was inclusive of all temporary supports and lifting/jacking hardware prepared by the Contractor.

5) Arc pipe of such a big span and section that its fabrication needed to be executed from ZHM in China and then arc shipped in pieces to UAE. Final assembly and preparation for installation in-house by the General Contractor.

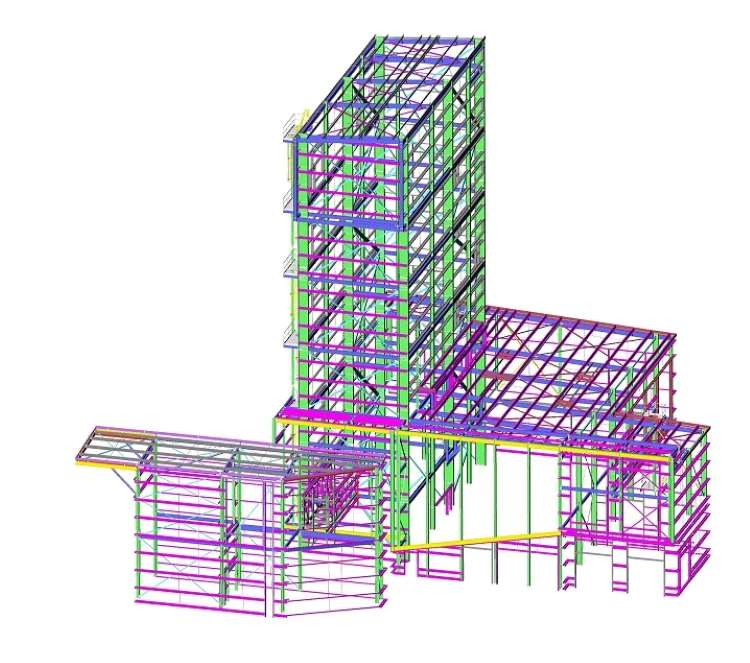

Sharjah Footbridge Arch Steel Structures: 3D BIM Model

Sharjah Footbridge Arch Steel Structures: 3D BIM Model

Sharjah Footbridge Arch Steel Structures: 3D BIM Model

Sharjah Footbridge Arch Steel Structures: 3D BIM Model

Sharjah Footbridge Arch Steel Structures: 3D BIM Model

Prior to this project, pedestrian crossing of the road in the Sharjah area was a serious hazard to the public. The Sharjah Urban Planning Council approved the unique footbridge design, which consists of a single arch that spanned over 92 metres length and 25 metres height. The arch was broken down into single 10 metre length pieces to accommodate less complex transport and easier handling. The arch would be constructed from ends and splice welded on site, where they would eventually meet in the centre section.

ZHM Huawu Steel during the tender phase submitted detailed documentation, showing full workflow, timescales, previous similar case studies and the necessary certification for CE marking of both raw materials and end product to BS EN 1090-1 and BS EN 1090-2 Execution Class 3. ZHM Huawu Steel’s engineers also effectively communicated with all the technical queries submitted both by the main contractor and the consultant in Europe. ZHM Huawu Steel had the advantage by having both offices and skilled personnel in the United Arab Emirates – the project country and the China - where the steel raw material was procured and the end product was fabricated .

Prior to production, ZHM Huawu Steel completed a comprehensive Inspection & Test Plan (ITP) with a breakdown of all the processes which included: welder qualification review, raw material inspection, component dimensional inspection, weld inspection and coating inspection. Strategic review, witness and certify hold points were incorporated for each of the stages. A 3rd party inspector was selected for the project as well by ZHM Huawu Steel and accepted by the client. After several iterations working with both the project client and consultant, the ITP was agreed and approved well before production started.

The steel bridge arch design required a 1524mm circular hollow section at a 60mm thickness at S355J2+N steel grade. Certain sections of the arch called for special steel grade S355+N Z25, where the Z25 required extra testing for through thickness ductility, important for special bridge components for both when high loads are transmitted through the thickness and also where large welds are specified on elements that are restrained against shrinkage. Few pipe mills in the world could produce this at such a low diameter to thickness ratio. The pipe section was also formed in a single piece using the JCOE process with a single longitudinal submerged arc weld. To bend the arch into a gradual curve required state of the art heat induction bending. Heat induction bending is used by locally heating the section along the length whilst pivoting it around a preset bend radius. The heat has to be very localized to prevent the previously bent section from plastically deforming producing an uncontrolled distortion. Each pipe was carefully checked using both manual methods and laser positioning equipment to calculate whether the bent product was within the project specific tolerances. The pipe weld was also inspected before and after heat induction bending.

After the heat induction bending, the pipes were slotted to include the hanger plates for the suspension cables. The footbridge deck followed a snake bend trajectory to improve aesthetics. Due to this, the geometry of the hangar plates all followed various planes relative to the plane of the arch which made fitting a complex matter. Using cutting edge laser sensors and highly skilled fitters, precise slotting and fitting was able to be carried out. All plates required full penetration double sided butt welding on a very thick section. This required a well-planned WPS (Weld Procedure Specification) and AWS trained welders working in confined spaces both inside and outside the pipe. Worker health and safety was always the number 1 priority and all appropriate measures were taken to prevent any accidents or health hazards.

While the client had called for the coating to be applied in the United Arab Emirates, there was a special requirement to coat certain sections that were inaccessible after welding of the diaphragm hanger plates. ZHM Huawu Steel applied the coating of which was inspected and approved by ZHM Huawu Steel’s SSPC certified coating inspector.

ZHM Huawu Steel completed and packed the pipe arch segments to minimize any chance for damage during shipment. The pipe segments were successfully delivered on time in May 2017 and construction is scheduled to commence in Q3 2017.

Sharjah Footbridge Arch Steel Structures: Curved Steel Plate for longitudinal submerged usrged welding

Sharjah Footbridge Arch Steel Structures: client inspectors factory inspection and acceptance of welding after NDT

Sharjah Footbridge Arch Steel Structures: arch pipes before blasting

Sharjah Footbridge Arch Steel Structures: arch pipes before blasting

Sharjah Footbridge Arch Steel Structures: arch pipes before blasting

Sharjah Footbridge Arch Steel Structures: base plate saddle flange T-joint welding inspection

Sharjah Footbridge Arch Steel Structures: Client notification

Sharjah Footbridge Arch Steel Structures: compartment partition stiffener plate welding

Sharjah Footbridge Arch Steel Structures: compartment partition stiffener plate welding inspection

Sharjah Footbridge Arch Steel Structures: instrumental geometrical dimentions inspection after assembly in workshop

Sharjah Footbridge Arch Steel Structures: Lifting ear lug welding inspection

Sharjah Footbridge Arch Steel Structures: Splicing Butt Full Penetration welding

Sharjah Footbridge Arch Steel Structures: Splicing Butt Full Penetration welding bevel treatment

Sharjah Footbridge Arch Steel Structures: Splicing Butt Full Penetration welding

Why ZHM Huawu Steel Footbridge Arch Steel Structures?

|

|

|

|

| Reliable and Customized Designs | Cutting Edge Designing Process | Free Online Price System | Easy Bolt-by-number Assembly |

|

|

|

|

| Over Two Decades of Experience | Value For Money | Unmatched in Quality and Craftmanship | Excellent Customer Service |

Would you like to see more information and images of ZHM’s Metal Steel Structure Footbridge Arch Steel Structures? Visit our Photo Gallery.

HOW CAN WE HELP YOU?

ZHM’s world-class team — together with our raw material suppliers and subcontractors — works to solve your most challenging design, engineering, farbrication or construction issues.

Contact ZHM by telephone at +86 135-8815-1981 (wechat and whatsapp) or send us your questions via email to info@zhmsteelworks.com